Method for setting a parking brake in a vehicle

A parking brake and controller technology, applied in the direction of brake, brake type, axial brake, etc., can solve problems such as clamping force error value, current drop, brake motor voltage disturbance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

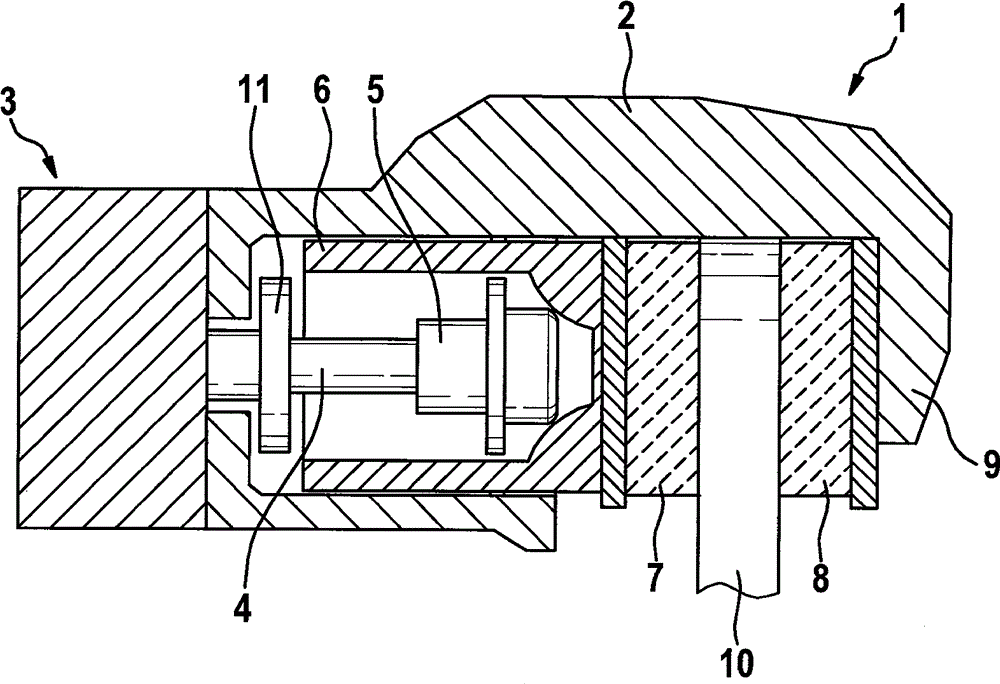

[0025] exist figure 1 shows an electromechanical parking brake 1 for immobilizing the vehicle in a stationary state. The parking brake 1 comprises a brake caliper 2 with a caliper 9 which engages a brake disc 10 . As an actuator, the parking brake 1 has an electric motor serving as a brake motor 3 , which drives a spindle 4 in rotation, on which a spindle nut configured as a spindle nut is rotatably supported. The spindle member 5. As the main shaft 4 rotates, the main shaft member 5 is adjusted in the axial direction. The spindle member 5 moves inside a brake piston 6 which is the seat of a brake lining 7 which is guided by the brake piston 6 towards the brake disc. 10 squeezes. On the opposite side of the brake disk 10 there is a further brake lining 8 which is fixedly held on the clamp 9 .

[0026] Inside the brake piston 6, the spindle member 5 can move axially forwards in the direction of the brake disc 10 during a rotational movement of the spindle 4, or vice versa....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com