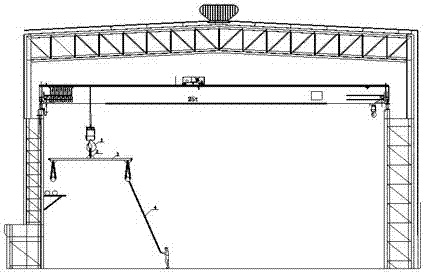

Hoisting method of driving pole method

A hoisting method and shoulder pole technology, which are applied in the directions of transportation and packaging, trolley cranes, load hanging components, etc., can solve problems such as unsmooth progress, dense distribution of production equipment, slow hoisting construction progress, etc., and achieve the effect of saving the use of machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

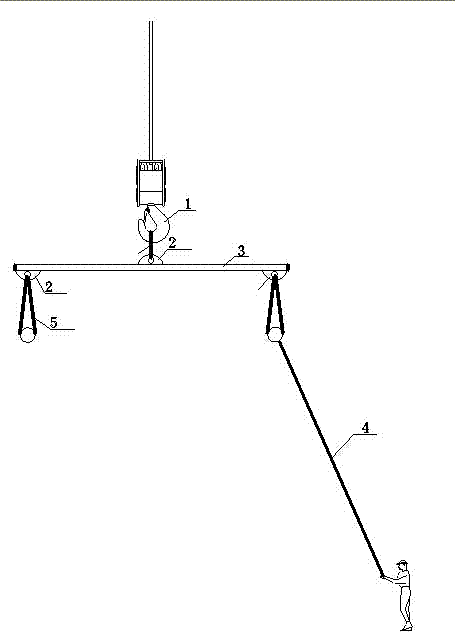

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] In the figure, a hoisting method of the present invention with a driving pole method includes the following construction steps:

[0019] Step 1 Make a shoulder pole hoisting device: select the lever according to the weight of the hoisting parts;

[0020] Step 2: Making the lifting lug 2: making the lifting lug 2 according to the weight of the hanger, the shape of the lifting lug 2 is semicircular, and the number is 3; the center of the upper surface of the lever 3 is provided with a lifting lug 2, Two ends of the lower surface of the lever 3 are respectively provided with a lifting lug 2;

[0021] Step 3 Fix the sling 5 and the hanger on the driving hook 1 through the lug 2 on the upper surface of the lever 3, and tie the traction rope 4 to the balance hanger;

[0022] Step 4 Run the crane, reverse the hanging part to the position where it needs to be hoisted,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com