Boiler two-stage economizer overhauling platform

A technology for overhauling platforms and energy savers, applied in the direction of hoisting devices, etc., can solve the problems of difficult installation, unsafe and inconvenient ladders, and occupying a lot of space, so as to facilitate maintenance or operation, and maintain the safety and reliability of equipment, which is beneficial to The effect of people passing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

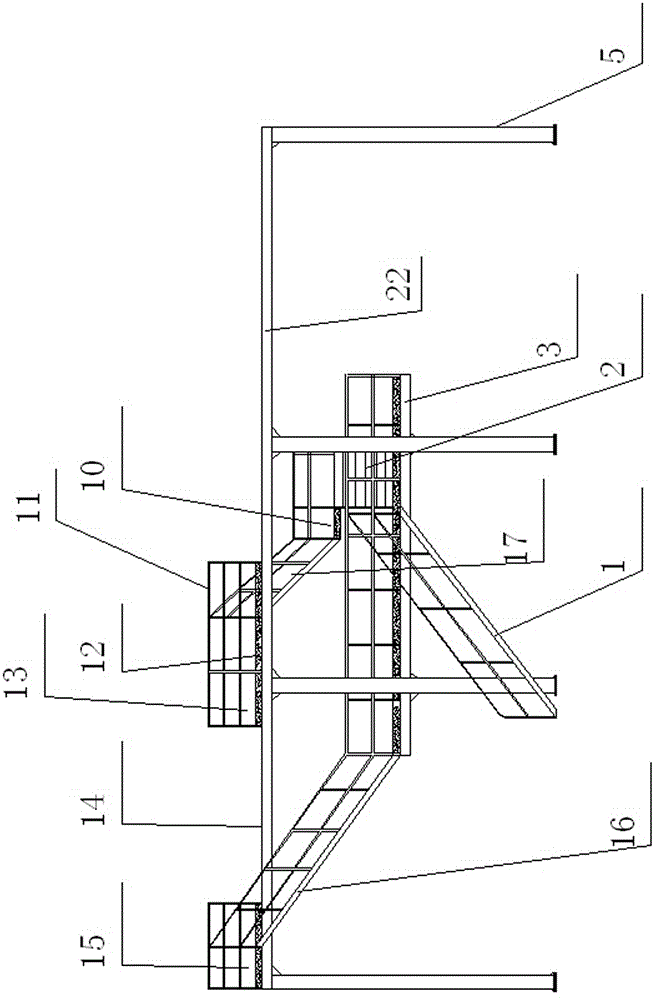

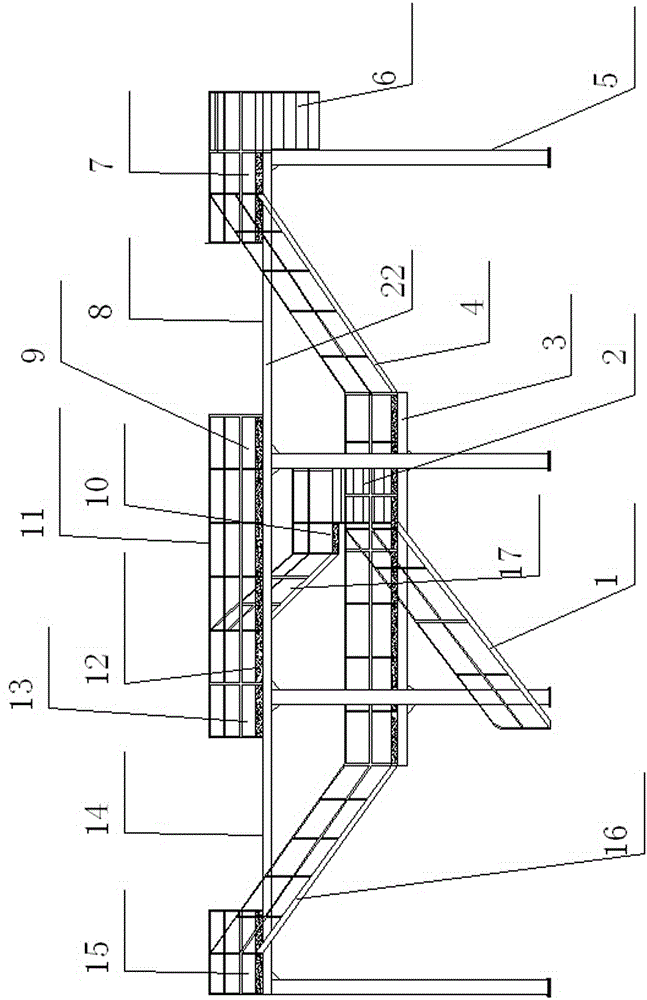

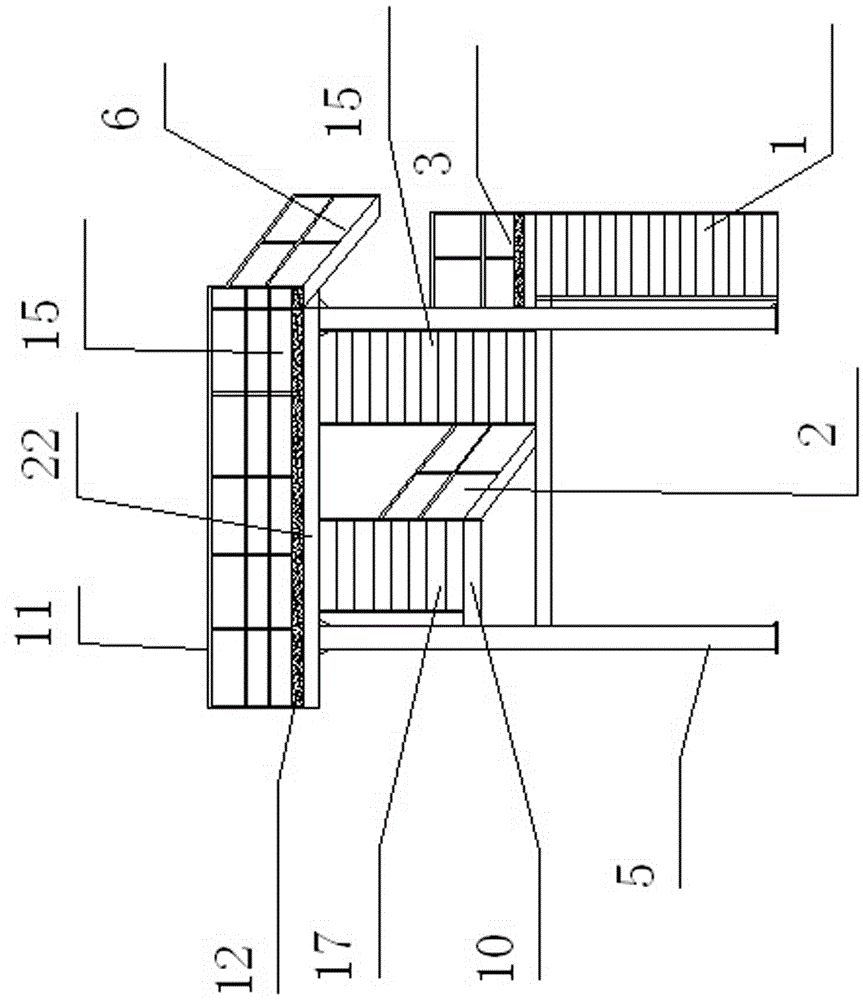

[0022] Such as figure 1 As shown, the maintenance platform of a boiler secondary economizer of the present invention includes an upper platform 22 for placing a secondary economizer, and the upper platform 22 is provided with a Corresponding to the first mounting base 14, the first mounting base 14 is used to install the left secondary economizer 18, and the upper platform 22 is respectively provided with the first upper maintenance platform 15 and the second Two upper maintenance platforms 13, the first upper maintenance platform 15 is arranged on the left side of the second upper maintenance platform 13, the first upper maintenance platform 15 and the second upper maintenance platform 13 cross the left boiler chimney 20 laterally; the upper The lower platform 3 is arranged below the platform 22, the first escalator 16 is arranged between the lower platform 3 and the first upper maintenance platform 15, the middle platform 10 is arranged between the lower platform 3 and the u...

Embodiment 2

[0025] Such as Figure 2 to Figure 6As shown, the maintenance platform of a boiler secondary economizer of the present invention includes an upper platform 22 for placing a secondary economizer, and the upper platform 22 is provided with a Corresponding to the first mounting base 14, the left secondary economizer 18 is placed on the first mounting base 14, and the upper platform 22 is respectively provided with a first upper maintenance platform 15 and a second The upper maintenance platform 13, the first upper maintenance platform 15 is arranged on the left side of the second upper maintenance platform 13, the first upper maintenance platform 15 and the second upper maintenance platform 13 cross the left boiler chimney 20 laterally; the upper platform 22 is provided with a lower platform 3 below, a first escalator 16 is arranged between the lower platform 3 and the first upper maintenance platform 15, a middle platform 10 is arranged between the lower platform 3 and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com