Upflow anaerobic sludge bed + anoxic/aerobic + anammox reactor process for deep denitrification of late landfill leachate

A flow-type anaerobic sludge and anaerobic ammonium oxidation technology, applied in water/sludge/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve unfavorable process engineering applications and reaction condition control Strict and other issues, to achieve the effect of saving oxygen supply, reducing toxic effects, and reducing sludge generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

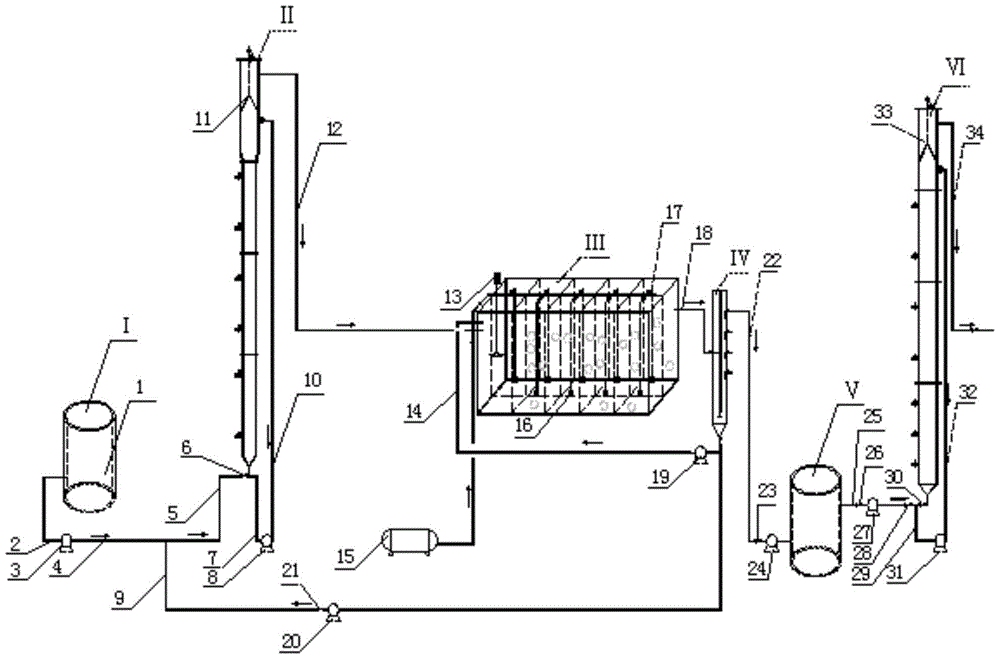

[0044] Combined example: The experimental water was taken from a waste landfill in Beijing, and the water quality is as follows: COD=2000~3000mg·L -1 , NH 4 + -N=700~2000mg·L -1 , TP=9~15mg·L -1 , TN=1000~2300mg·L -1 , NO x - -N=0.5~15mg·L -1 , PH=7~8. Conventional water quality indicators such as COD, ammonia nitrogen, nitrite nitrogen, and nitrate nitrogen all adopt national standard methods. TON, TN, TOC, IC, TC, etc. use TN / TOC analyzer (Multi N / C3000, Jena, Germany). The integrated water tank and the intermediate water tank are made of stainless steel, and the effective volume is 50L and 20L respectively. The effective volumes of UASB and ANAOR are 8.25L and 4.25L, respectively. The A / O reactor is made of plexiglass with an effective volume of 15L, divided into 10 compartments evenly. The first compartment is an anoxic zone, and the rest are an aerobic zone. The material of the secondary sedimentation tank is plexiglass, and its effective volume is 20L, and each cycle pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com