Support ring component chromium plating method and shield jig

A technology for supporting rings and components, applied in the direction of electrolysis components and electrolysis processes, can solve the problems of leakage of chromium, rough chromium layer, long production cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

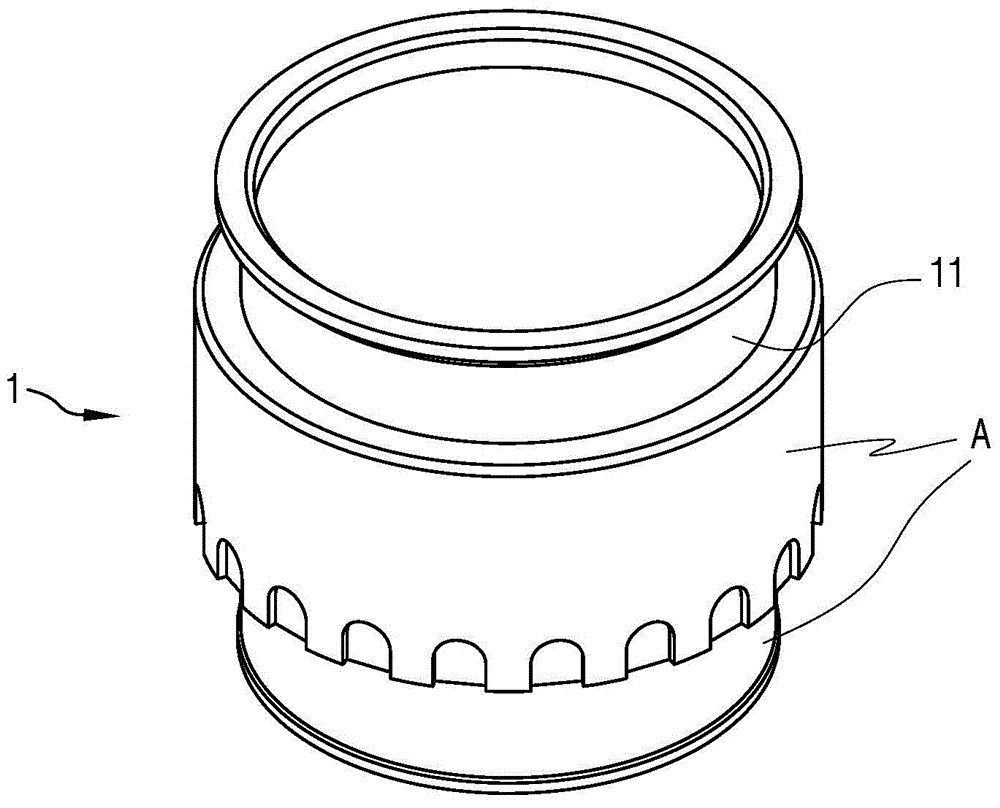

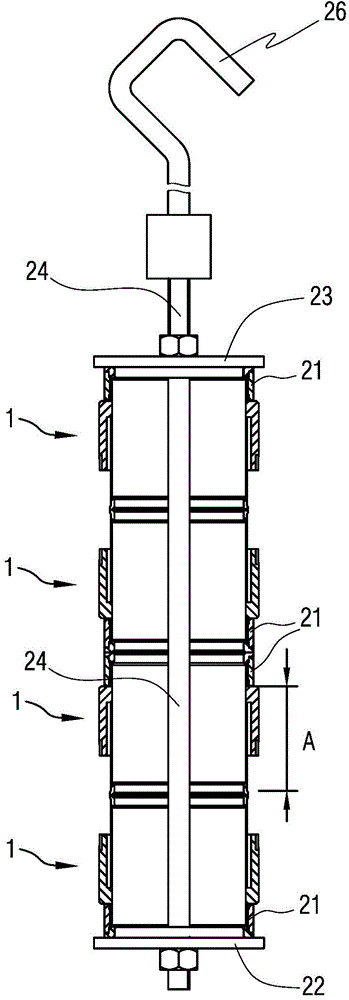

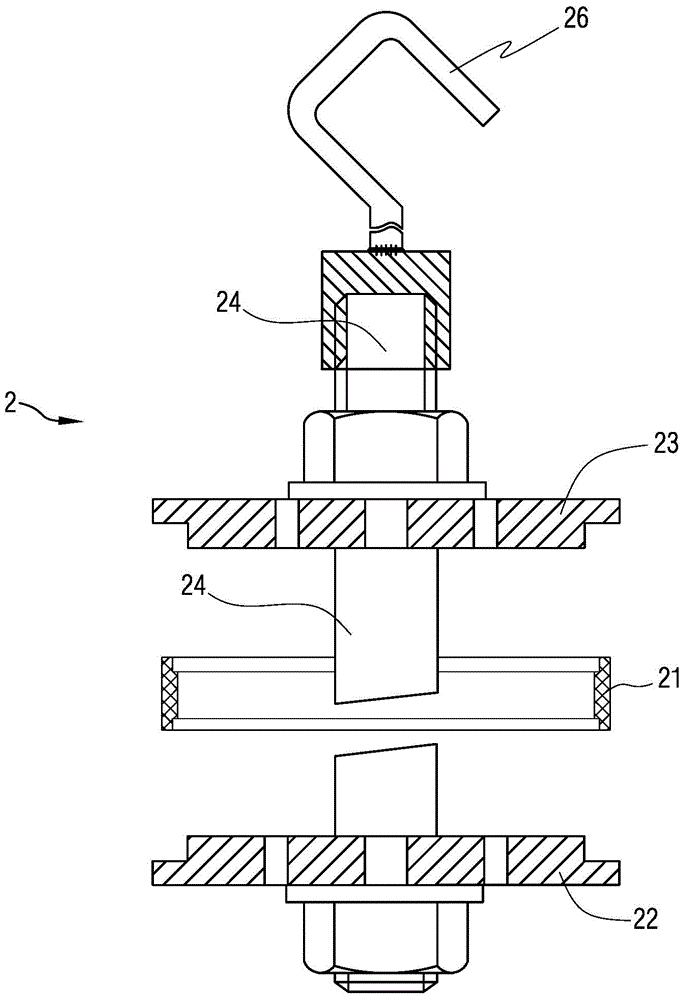

[0022] The present invention provides a method for figure 1 The chrome-plating method and fixture of the shown support ring assembly 1. Specifically, figure 1 The support ring assembly 1 has a cylindrical structure, the upper end of the support ring assembly 1 has a groove 11, and there is a chrome-plated outer circular surface A immediately below the groove 11; except for the chrome-plated outer circular surface A Except that chrome plating is required, the remaining surfaces of the support ring assembly 1 do not need chrome plating. In a specific embodiment, it is required that the diameter of the chrome-plated outer circular surface A before chrome-plating is φ74.98...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com