Integral bridge and bridge material

An integrated, bridge-based technology, applied to bridge materials, bridges, bridge parts, etc., can solve problems such as large impact, complicated manufacturing process, and difficult mechanization, and achieve the effect of short construction time on site, shortened construction period, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

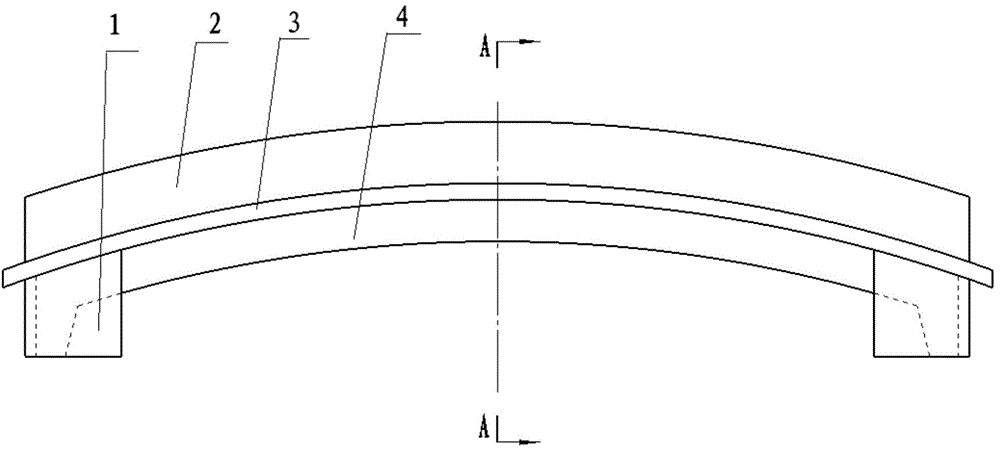

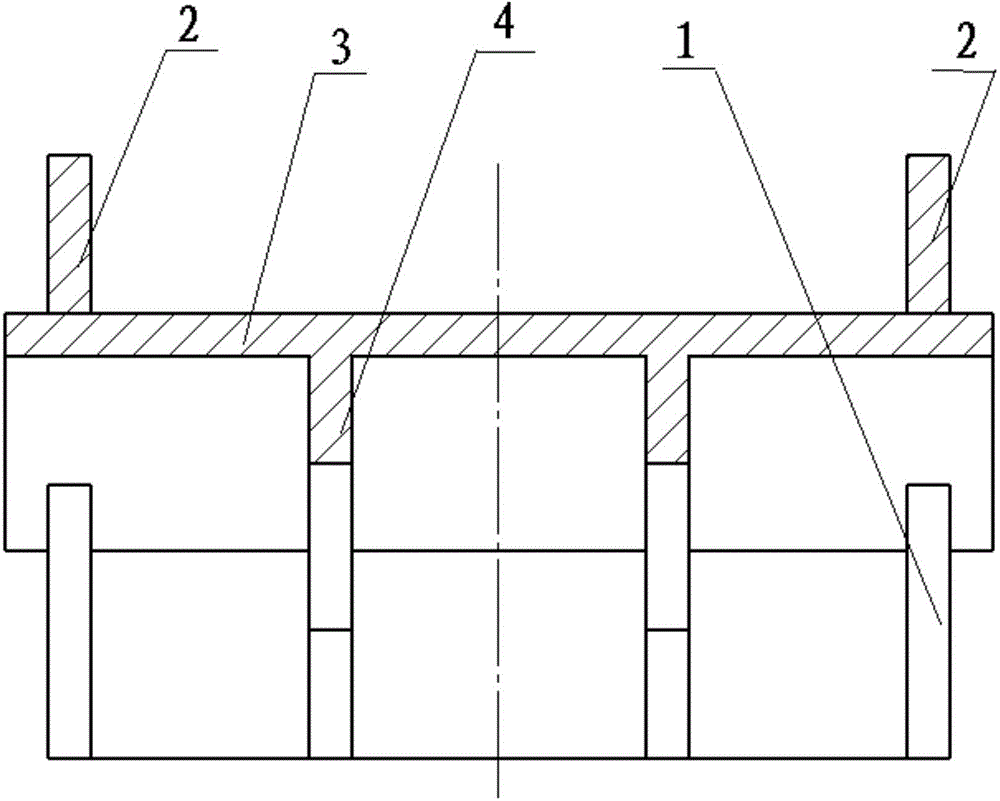

[0026] Such as figure 1 with figure 2 As shown, there is no obvious difference in appearance between the integrated bridge of the present invention and the existing bridge. A one-piece bridge may only have a deck 3 . For ease of installation, the one-piece bridge may include support columns 1 . In order to increase the flexural strength, the one-piece bridge may include stiffeners 4 . For the safety of pedestrians and vehicles, the integrated bridge can include guardrails 2 .

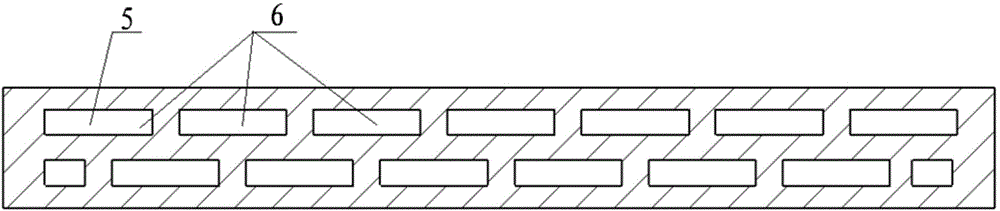

[0027] The difference between the integrated bridge of the present invention and the prior art lies in that the internal structures of the bridge components such as the support column 1, the guardrail 2, the bridge deck 3 and the reinforcing rib 4 are different from the prior art. The support column 1, the guardrail 2, the bridge deck 3 and the reinforcing rib 4 al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com