Thermal insulation technology for wallboard frame

A wallboard and frame technology is applied in the field of wallboard frame thermal insulation and wallboard frame thermal insulation system in prefabricated housing, which can solve the problems of prefabricated housing thermal insulation performance failing to meet energy-saving requirements, increasing living costs, and poor thermal insulation performance. Achieve the effect of good thermal insulation performance, complete thermal insulation system and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

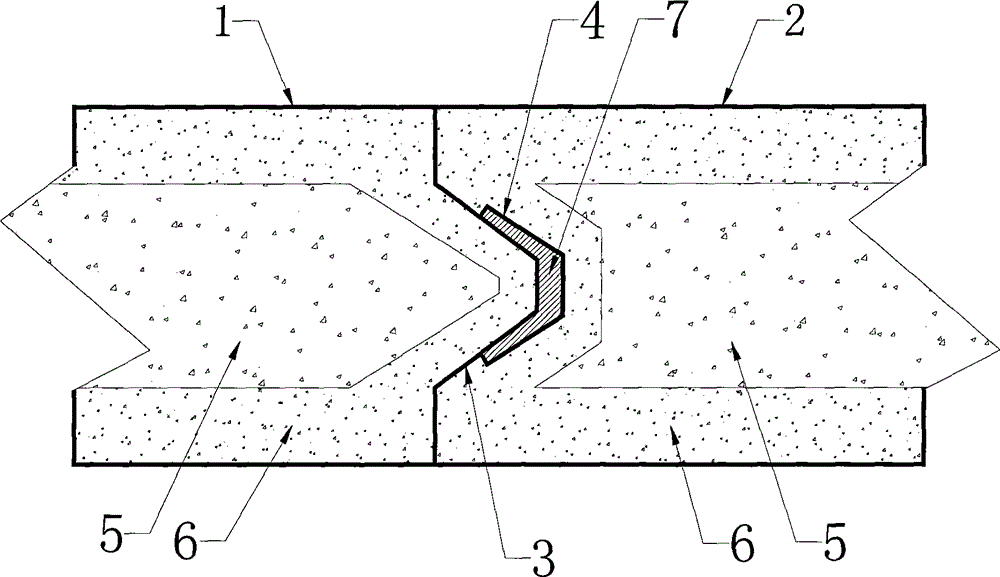

[0018] The convex wall panel mold and the concave wall panel mold are used to pour concrete once, arrange the reinforcement cage, pour the insulation material, and pour concrete twice to obtain the convex wall panel frame 1 and the concave wall panel frame 2, which are installed by a crane. The tongue 3 of the convex wall panel frame 1 is connected with the notch 4 of the concave wall panel frame 2, and the position of the tongue-and-groove joint is added with an insulating material such as extruded board, polyurethane board, polyethylene or polystyrene as an insulating layer. The tongue-and-groove insulation layer 7 and the wallboard inner insulation layer 5 are combined to form a wallboard frame insulation system, so that any cross-sectional position of the wallboard frame has an insulation layer to avoid cold bridges.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com