Plastic steel formwork

A formwork and plastic steel technology, which is applied in the field preparation of formwork/formwork components and building components, construction, etc., can solve the problems of easy deformation of plastic steel, achieve good protection performance, reliable sealing connection, and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

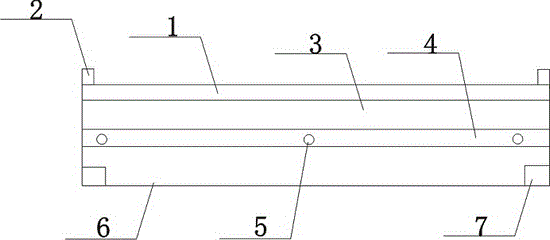

[0015] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0016] Such as figure 1 The preferred embodiment of the plastic-steel formwork shown in the present invention includes a panel 1, the upper surface of the panel 1 is provided with steel connecting wedges 2 near the two sides, the steel connecting wedges 2 are fixed on the panel 1, and the lower surface of the panel 1 is provided with ribs The plate 3, the rib 3 and the panel 1 are consolidated into a whole by anchoring, the screws are built between the rib 3 and the panel 1, the lower surface of the rib 3 is provided with a reinforced steel flange plate 4, and the reinforced steel flange 4 A gasket is connected between the upper surface and the rib plate 3, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap