Advanced pier column pre-arranging gob-side entry retaining method

A technology for empty entry retaining and pier column, which is applied in earth-moving drilling, ground mining, underground mining and other directions, can solve the problems of high cost, low support resistance, high operation risk, etc., and achieves low risk and convenient installation. , the effect of a comfortable working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

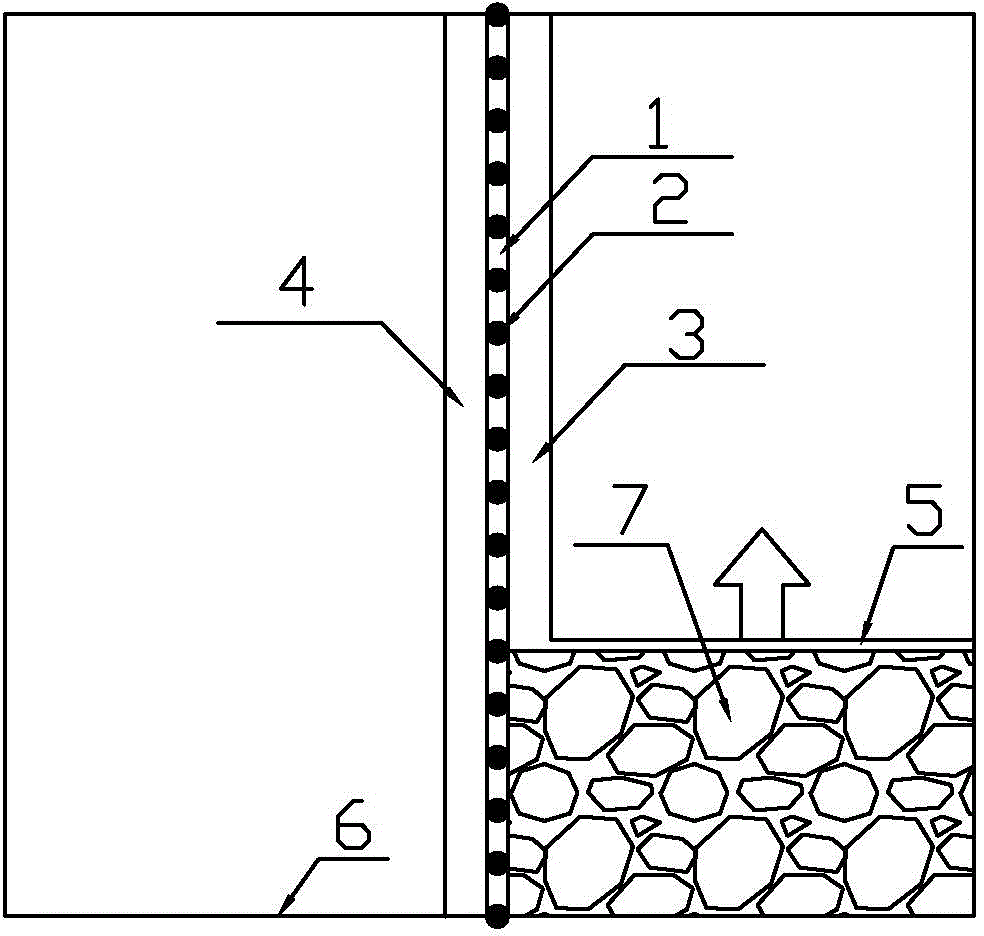

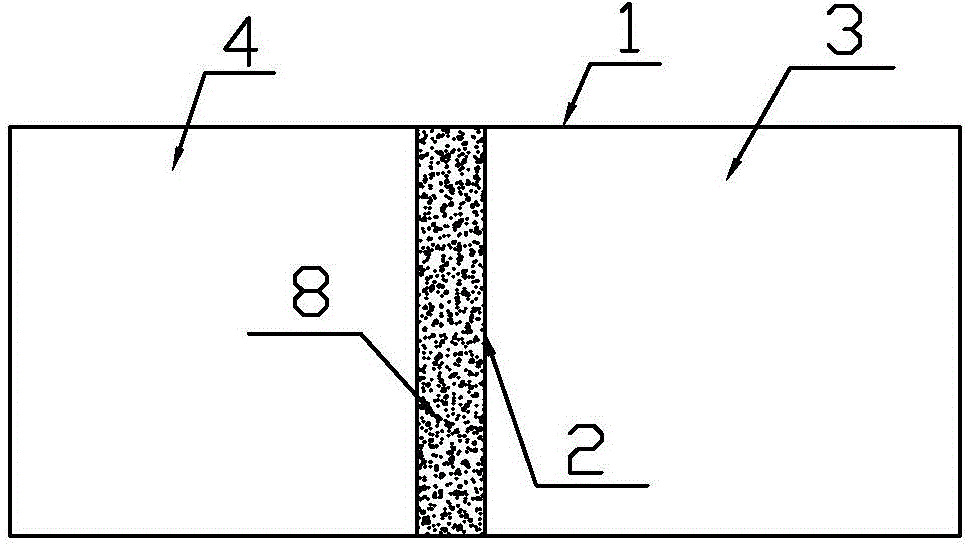

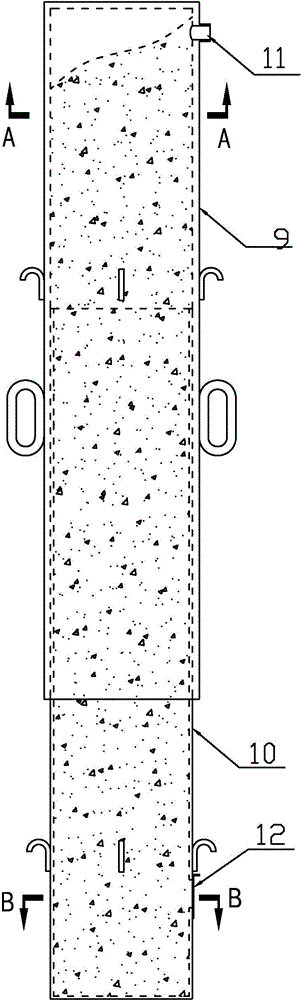

[0025] Attached below Figure 1-5 Specific embodiments of the present invention are further described in detail.

[0026] In order to alleviate the tense situation of excavation replacement and improve the recovery rate of high-quality coal resources in a certain mine, the mining roadway layout of the working face adopts the advanced reserved piers and gob-side entry retention technology. The specific implementation steps are as follows:

[0027] 1) First excavate a small-section rectangular roadway (clear width×clear height: 4000mm×3000mm), and then brush the side to the design section size (clear width×clear height: 6400mm×3000mm) to form a complete roadway (1);

[0028] 2) Lag the brush side working face 20m, assemble the steel pipes 9 and 10 near the middle of the roadway 1 and inject the sand filling material 8 through the sand filling port 11, install the piers 2 one by one according to the row spacing of 1.5m, so that the two sides of the pier 2 Design cross-sectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com