Energy-saving heating network heater

A heat network heater and water heating technology, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., can solve the problem of damage to the support of heat exchange tubes and support plates, rising condensed water temperature, and steam Problems such as high inlet flow rate, to ensure the safety of equipment operation, reduce the steam flow rate, and achieve the effect of large heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

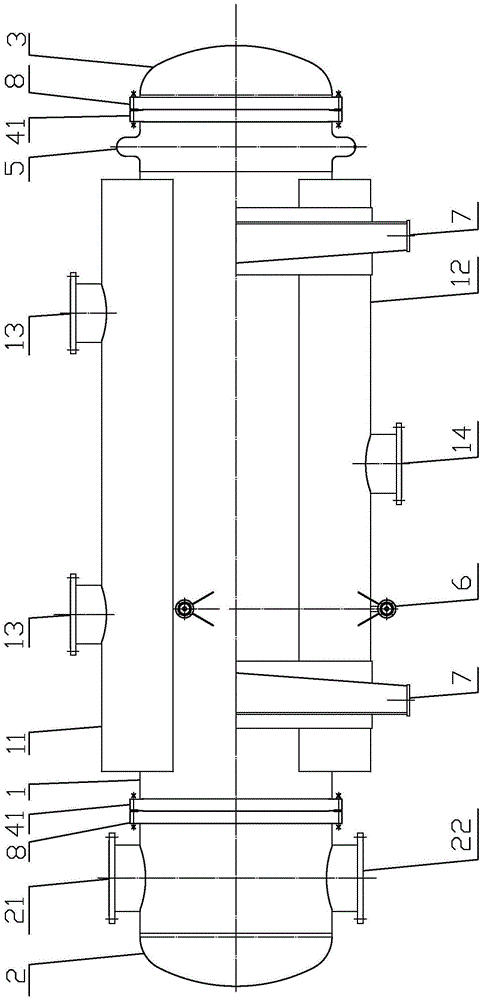

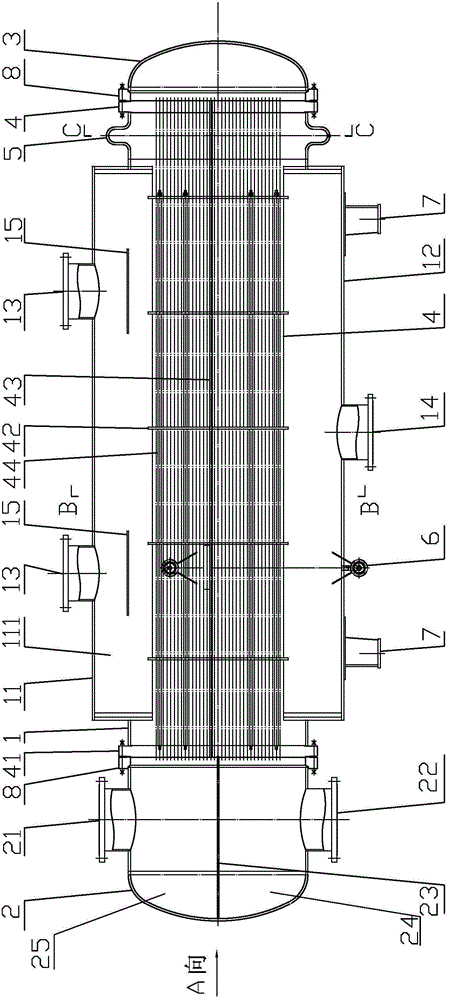

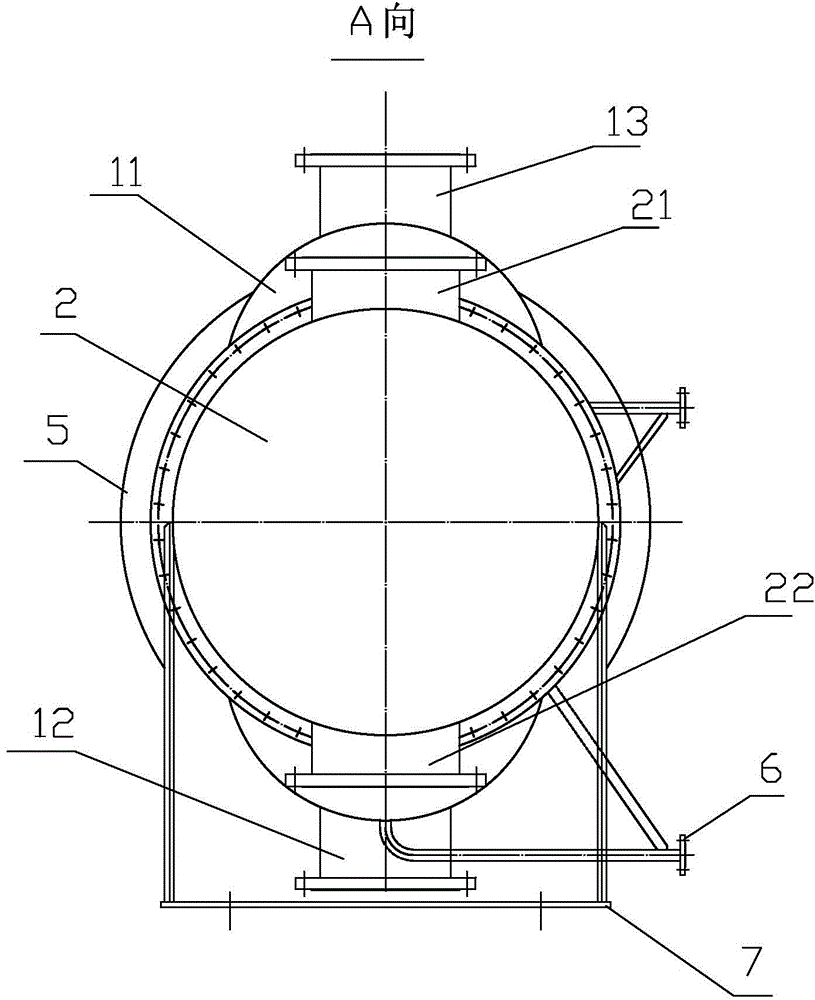

[0040] Refer to the attached figure 1 To attach Figure 7 The energy-saving heating network heater of the present invention will be described in detail below.

[0041] The energy-saving heating network heater of the present invention has a structure comprising a shell 1, a front end tube box 2, a rear end tube box 3 and a tube bundle 4, the front end tube box 2 is arranged on the front part of the shell 1, and the rear end tube box 3 is arranged on the At the rear of the shell 1, the tube bundle 4 is arranged in the shell 1, and the upper and lower parts of the front end tube box 2 are respectively provided with a heated water outlet connecting pipe 21 and a heated water inlet connecting pipe 22, and the shell 1 is a cylinder The upper and lower parts of the housing 1 are respectively provided with a steam buffer enclosure 11 and a hydrophobic storage enclosure 12. The sections of the steam buffer enclosure 11 and the hydrophobic storage enclosure 12 are respectively arc-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com