Evaluation method of crude oil paraffin inhibitor

An evaluation method and wax inhibitor technology, which are applied in the field of oilfield chemistry, can solve the problems affecting the effective evaluation of the wax inhibitor, long time, inaccurate data, etc., to achieve accurate and reliable experimental results, shorten the evaluation time, and good contrast. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

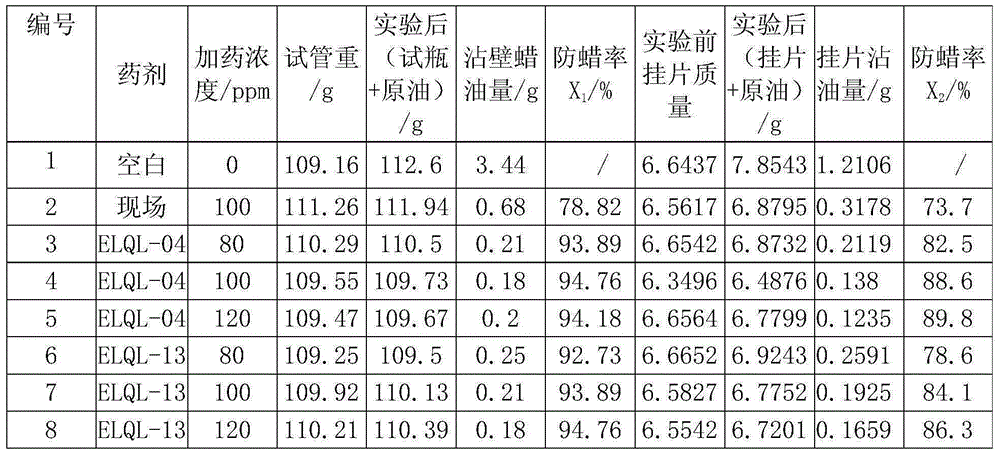

Embodiment 1

[0028] A kind of evaluation method of crude oil wax inhibitor, comprises the following steps:

[0029] 1) Take a sample: take the crude oil emulsion that has not been separated into water as a sample;

[0030] 2) Add wax inhibitor: Use a 100ml centrifuge test tube, add 80g of on-site oil-water sample after weighing, cover the bottle stopper and place it in a water bath with constant temperature (oilfield field temperature), after a certain period of constant temperature (the purpose is that the oil-water sample reaches Take it out; add a certain concentration of anti-wax agent, and shake it by hand for 100 times to mix the medicine and oil evenly;

[0031] 3) Wax stained wall weighing test piece treatment: pre-treated the surface of the on-site material test piece (the size can be customized according to the internal volume of the centrifuge tube, such as 5cm / 0.15cm / 1.3cm / 0.8cm (long, thick and wide holes)), Analytical balance weighs and records its initial mass, and then use...

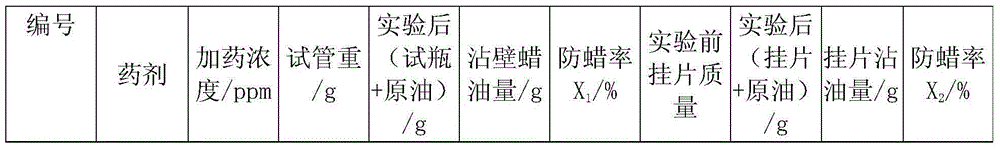

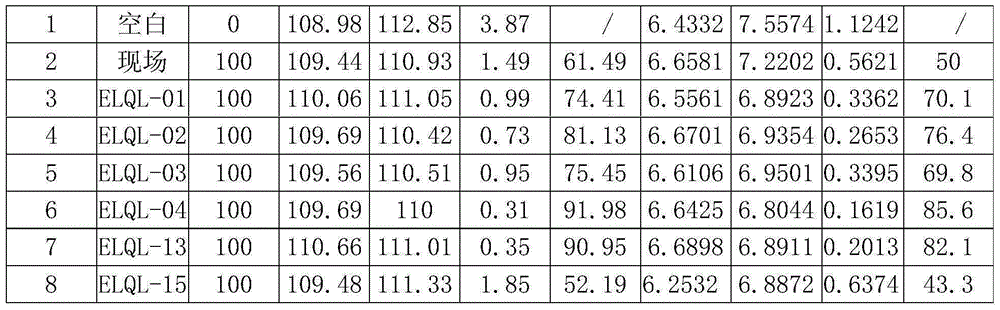

Embodiment 2

[0050] A kind of evaluation method of crude oil paraffin inhibitor, process step, use crude oil, experiment temperature etc., are the same as embodiment 1.

[0051]

[0052] This embodiment has positive effects such as simplicity, quickness, reliable data, and the ability to more accurately screen and evaluate wax inhibitors suitable for use in oil fields, and can slow down the precipitation of wax around the well wall, production casings, and oil pipelines. Guarantee the normal production and operation of the oil field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com