Novel grounded copper rod and assemblies thereof

A copper rod, a new type of technology, applied in the direction of connecting contact materials, etc., can solve the problems of poor grounding, re-drilling, waste of time and cost, etc., to achieve stable and firm contact, reduce construction costs, and have no safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

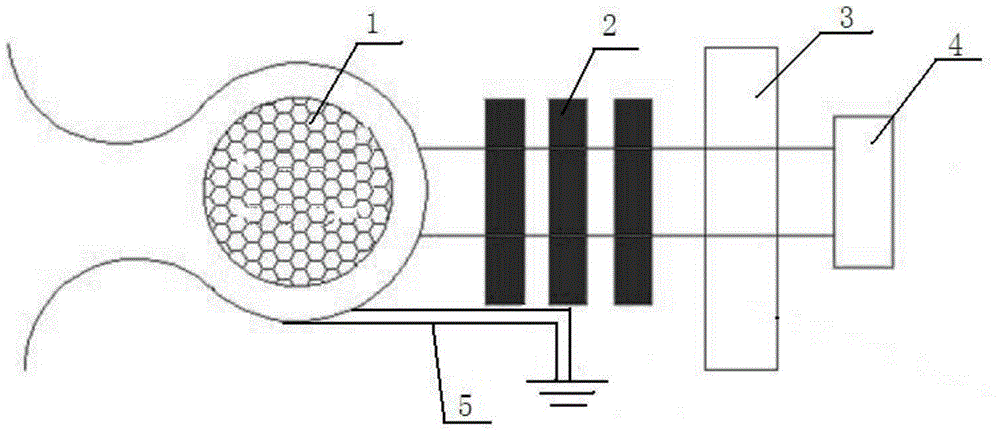

[0025] Such as figure 1 As shown in , this embodiment discloses a new type of grounding copper rod and its components, which include several copper rods 1, cable trays 3, and insulating terminals 4, and the above-mentioned copper rods 1 and cable trays 3 are connected through the above-mentioned insulating terminals 4, An insulating material 2 is provided between the insulating terminal 4 and the copper rod 1 , and the insulating material 2 ensures the insulation of the insulating terminal.

[0026] The above-mentioned copper rod 1 is also connected to a grounding wire 5, and the above-mentioned grounding wire 5 is also connected to a wiring cabinet and a grounding bar; the above components are combined into a complete grounding system.

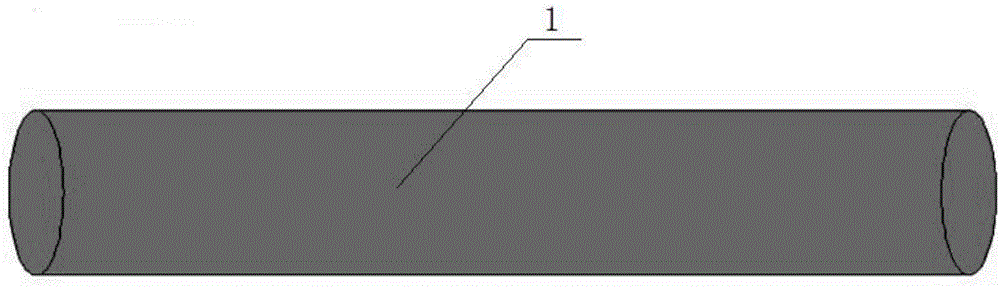

[0027] Such as figure 2 As shown, the above-mentioned copper rod 1 is a cylindrical copper pipe, its specification is generally 4*40mm, and its length is 6 meters, which is equivalent to an effective area of 4*40mm, and its diameter is ab...

Embodiment 2

[0030] Such as figure 1 As shown in , this embodiment discloses a new type of grounding copper rod and its components, which include several copper rods 1, cable trays 3, and insulating terminals 4, and the above-mentioned copper rods 1 and cable trays 3 are connected through the above-mentioned insulating terminals 4, An insulating material 2 is provided between the insulating terminal 4 and the copper rod 1 , and the insulating material 2 ensures the insulation of the insulating terminal.

[0031] The above-mentioned copper rod 1 is also connected to a grounding wire 5, and the above-mentioned grounding wire 5 is also connected to a wiring cabinet and a grounding bar; the above components are combined into a complete grounding system.

[0032] Such as figure 2 As shown, the above-mentioned copper rod 1 is a cylindrical copper pipe, its specification is generally 4*40mm, and its length is 6 meters, which is equivalent to an effective area of 4*40mm, and its diameter is ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com