Motor for rolling-assisting transmission

A motor and body technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of easy burnout, poor mechanical reliability, low overload capacity, etc., to improve electrical and mechanical reliability, excellent speed regulation performance, overload powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

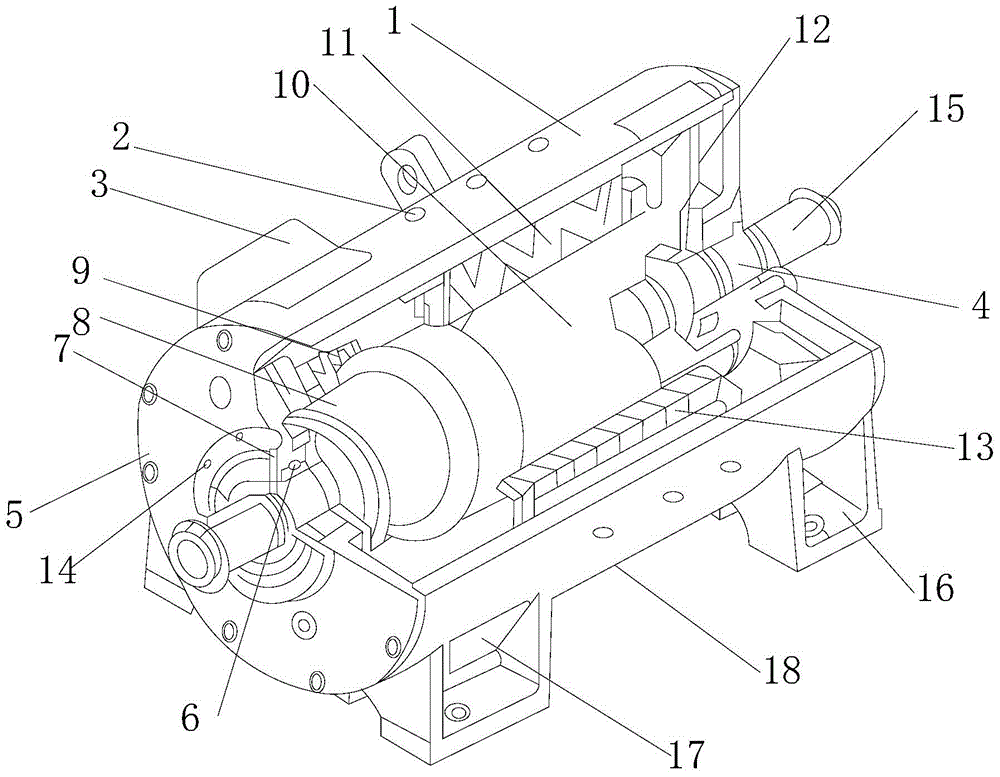

[0012] The present invention will now be further described in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0013] Such as figure 1 A rolling auxiliary transmission motor shown has a body 1 and a machine base 2, the outer surface of the body 1 is provided with an outlet box 3, the center of the body 1 is provided with a rotating shaft 4, and the two ends of the body 1 End caps 5 are provided, bearings 6 are provided at both ends of the rotating shaft 4, bearing covers 7 are provided on the bearings 6, a commutator 8 is provided on the rotating shaft 4, a brush holder 9 is provided on the commutator 8, and the middle of the rotating shaft 4 An armature 10 is provided with a main pole iron core 11 on the armature 10, a fan 12 is provided in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com