Bakery shortenings from palm diacylglycerol

A technology of palm diacylglycerol oleate and palm diacylglycerol, which is applied in baking, food science, dough processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation of palm diacylglycerol shortening involves the steps of blending, cooling, plasticizing and tempering of the oil mixture. Palm-based shortening does not need to be hydrogenated because palm oil has a natural solids content. Therefore, palm-based shortening does not have the harmful effects of trans fatty acids.

[0060] The palm-based bakery of the present invention is prepared by physically blending or mixing the palm diacylglycerol stearin with the palm mid-fraction or the palm diacylglycerol oleate with the palm stearin Food shortening. Preferably, the blending or mixing is performed under mechanical agitation, and more preferably under stirring. The mixture is preferably stirred at about 70°C until a homogeneous mixture is obtained. The mixture is then subjected to cooling followed by plasticizing under continuous agitation until the mixture achieves complete crystallization and becomes a shortening. Those of ordinary skill in the art will recogn...

Embodiment 1

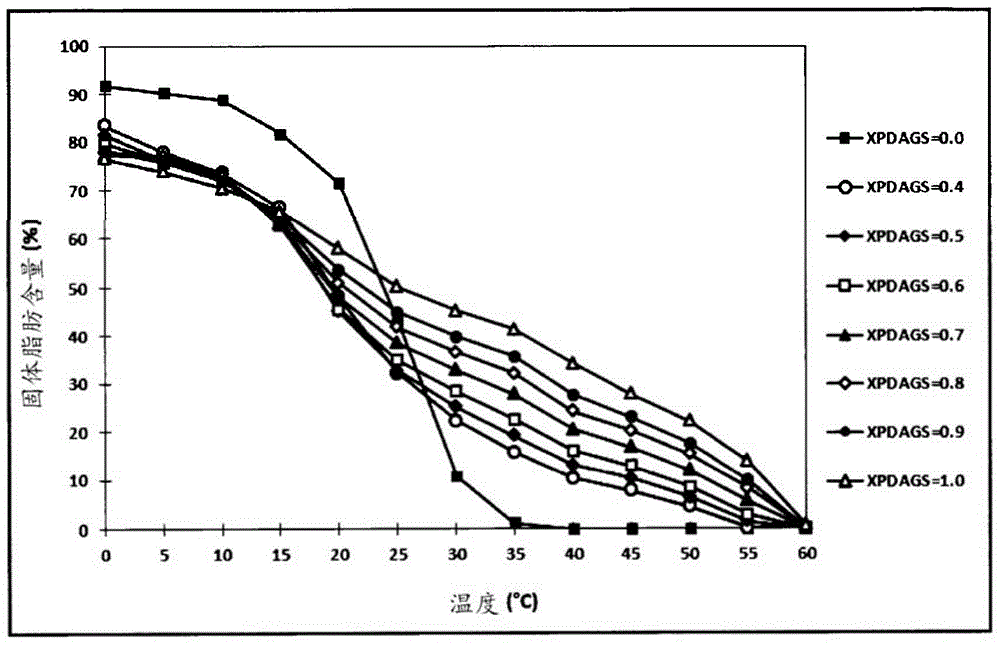

[0086] Example 1: Palm Diacylglycerol (PDAG) Stearate / Palm Mid Fraction (PMF)

[0087] This example illustrates one embodiment of a bakery shortening according to the invention, wherein the bakery shortening comprises palm diacylglycerol stearin and palm mid-fraction prepared using the method described above.

[0088] Readings were taken for shortenings containing varying amounts of palm diacylglycerol (PDAG) stearate and palm mid-fraction (PMF) and are shown in Table 1.

[0089] Table 1: Physicochemical characteristics of shortening containing PDAG stearate and PMF

[0090]

[0091] PDAG stearate has a high composition of palmitic acid and this contributes to the high SMP of 55.07°C; making it undesirable for food applications. Meanwhile, hard PMF, which is characterized by a sharp melting point, has a low SMP of 32.10°C. The blend of PDAG stearate and PMF appeared to slowly decrease the SMP of the binary mixture from about 55.07°C to 50.6°C (Table 1). This indicates ...

Embodiment 2

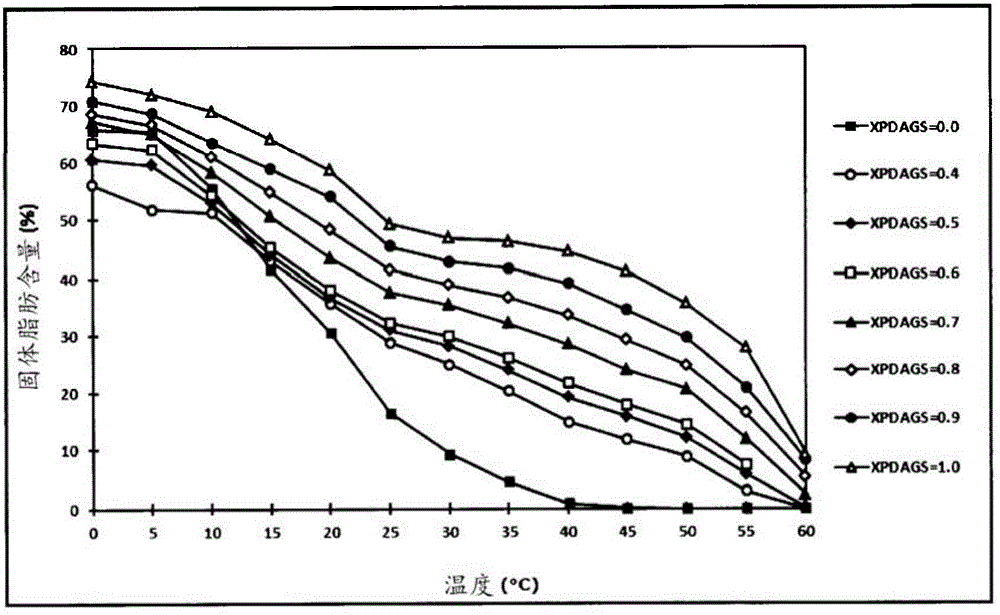

[0095] Example 2: Palm Diacylglycerol (PDAG) Stearate / Refined, Bleached and Deodorized Palm Oil (RBDPO)

[0096] Readings were taken for shortenings containing palm diacylglycerol (PDAG) stearate and refined, bleached, and deodorized (RBDPO) and are shown in Table 2.

[0097] Table 2: Physicochemical characteristics of shortening containing PDAG stearate and RBDPO

[0098]

[0099]

[0100] RBDPO with comparable amounts of unsaturated and saturated fatty acids has an SMP of about 38.8°C. PDAG stearate with a high amount of palmitic acid contributes to the high SMP of 59.40°C, making this undesirable for food applications. Similar to PMF, blends of RBDPO with PDAG stearate from 10% to 60% showed a decrease in SMP values for binary mixtures of PDAG stearate and RBDPO from about 51.98°C to about 50.2°C (Table 2) .

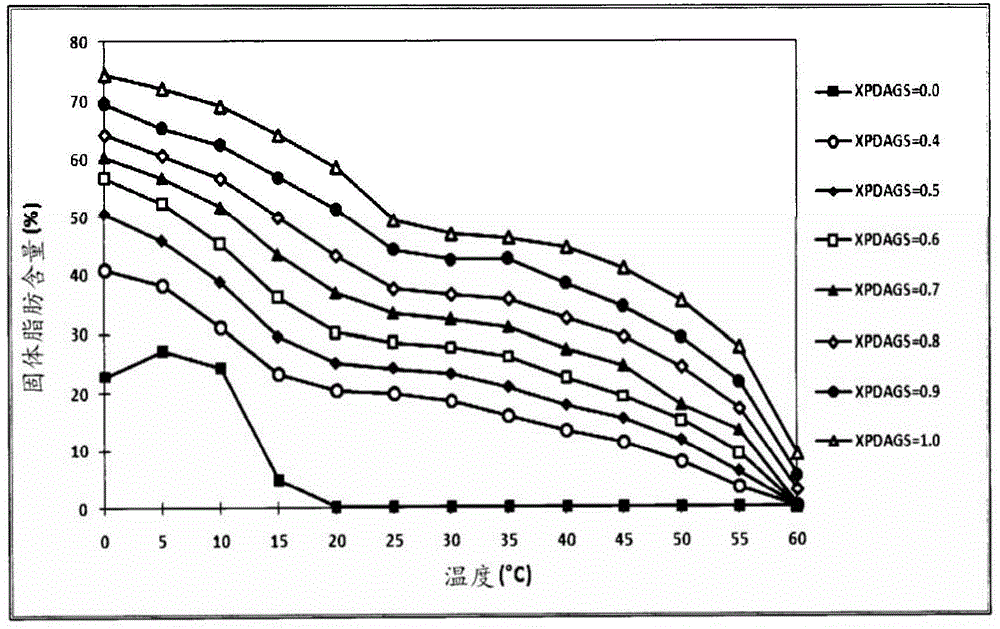

[0101] Both RBDPO and PMF have different SFC curves. Similar to PMF, blends containing 10% to 60% of RBDPO and PDAG stearate showed a decrease in the SFC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com