Process for production of micronutrient rich zero trans shortenings

A technology of micronutrients and shortening, applied in the direction of edible oil/fat, edible oil/fat phase, extended composition, etc., can solve the problem of not paying attention to selection and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

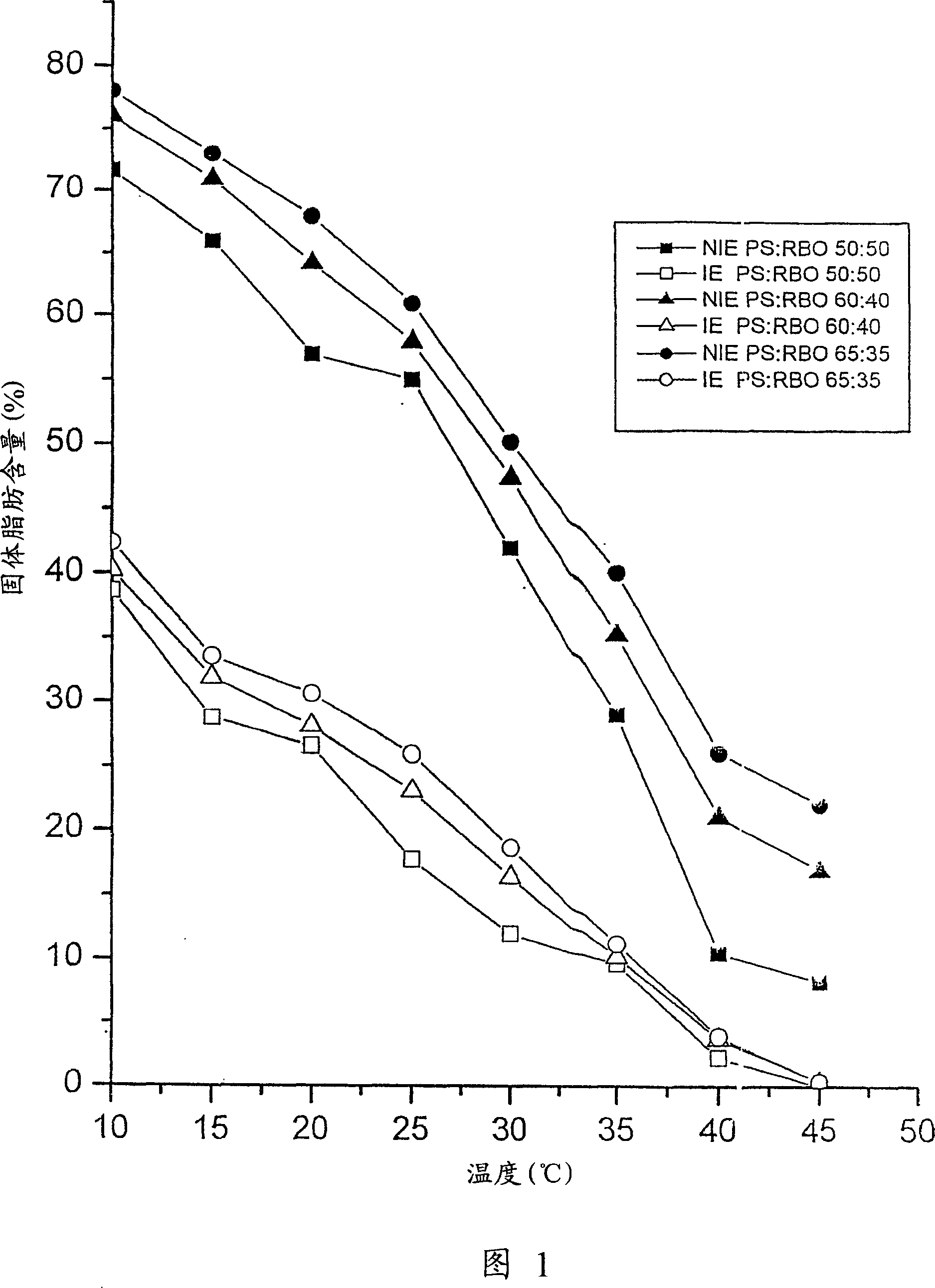

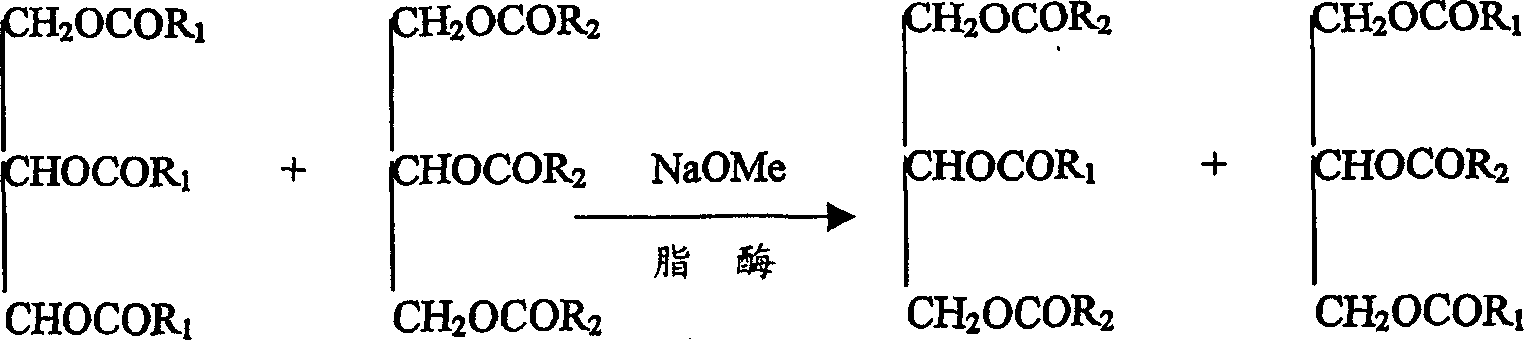

[0034] 18 kg of palm stearin, rice bran oil mixture in a ratio of 50:50 was heated to 80° C. under vacuum and 0.5% sodium methoxide catalyst was added, and the mixture was vigorously stirred at this temperature for 30 minutes. After reacting for 30 minutes, the mixture was cooled to 70°C. A measure of citric acid to deactivate the catalyst (117 g) was dissolved in 2.5 liters of water and added to the reactor with slow stirring for 30 minutes and the aqueous layer was separated. The reaction mixture was washed to neutral using hot water at 85 °C. Deodorization of interesterified fats (1-5 mabr, 160°C, 2.5 hours). The resulting interesterified fat was cooled to 70°C and processed using a margarine crystallizer.

[0035] The coolant temperature of the margarine crystallizer is adjusted to 20°C so that the equilibrium temperature of the product obtained at the mutator feed barrel is 50°C, and 8 kg of homogeneously molten interesterified fat mixture is at 70°C to A feed rate of ...

Embodiment 2

[0037] 20 kg of palm stearin, rice bran oil mixture in a ratio of 60:40 was heated to 85° C. under vacuum (80 mmHg) and 0.5% sodium methoxide catalyst was added, and the mixture was vigorously stirred at this temperature for 60 minutes. After reacting for 60 minutes, the mixture was cooled to 70°C. A measure of citric acid to deactivate the catalyst (130 g) was dissolved in 2.5 liters of water and added to the reactor with slow stirring for 30 minutes and the aqueous layer was separated. The reaction mixture was washed to neutral using hot water at 80 °C. Deodorization of interesterified fats (1-5 mabr, 160°C, 2.5 hours). The resulting interesterified fat was cooled to 70°C and processed using a margarine crystallizer.

[0038] The coolant temperature of the margarine crystallizer was adjusted to 15°C. 10 kg of the homogeneous molten interesterified fat mixture was fed into a margarine crystallizer at 70°C at a feed rate of 10 kg / hour and into a scraped surface heat exchang...

Embodiment 3

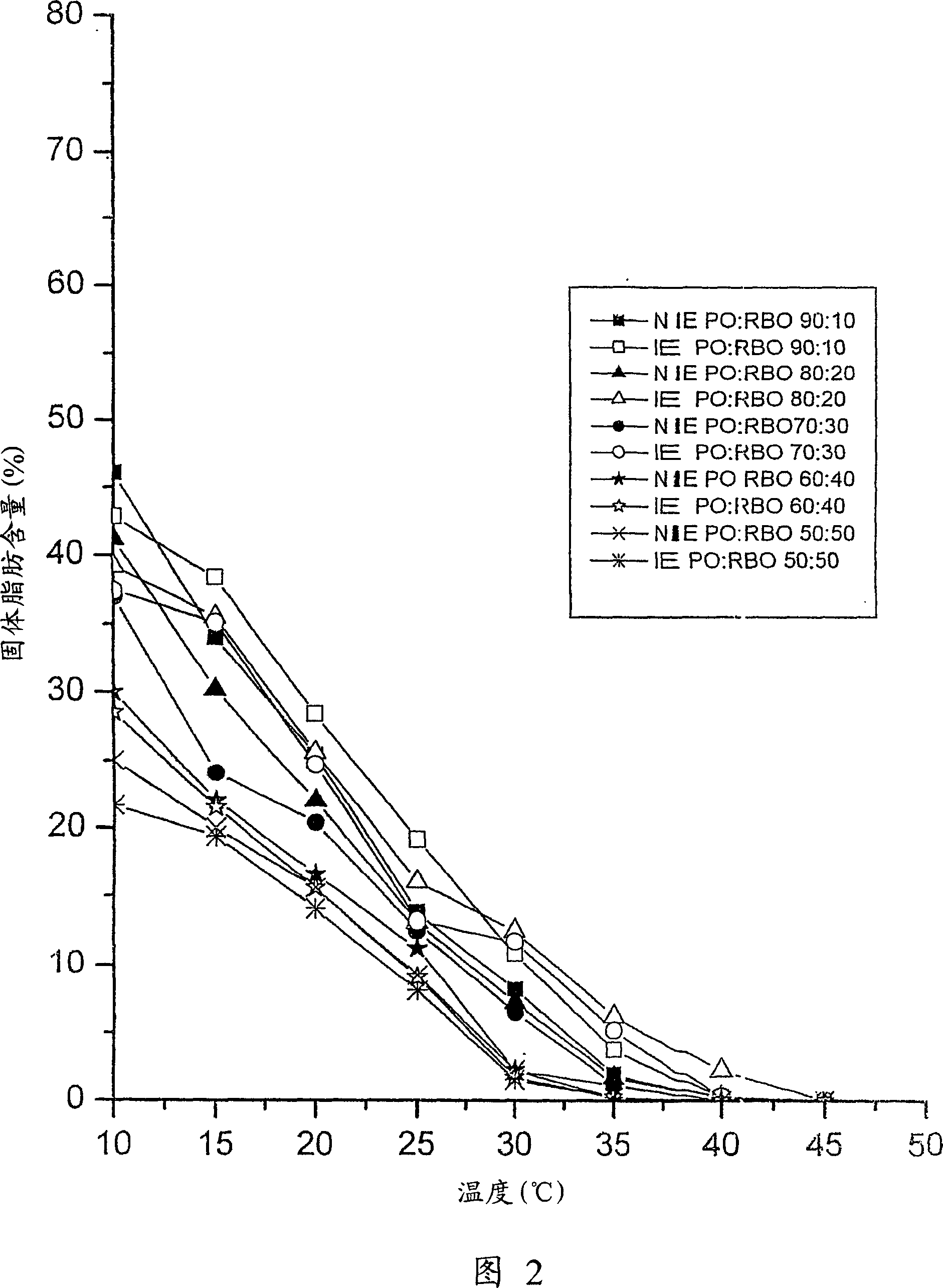

[0040] 18 kg of palm oil, rice bran oil mixture in a ratio of 70:30 was heated to 85° C. under vacuum (80 mmHg) and 0.5% sodium methoxide catalyst was added, and the mixture was vigorously stirred at this temperature for 30 minutes. After reacting for 30 minutes, the mixture was cooled to 70°C. A measure of citric acid to deactivate the catalyst (117 g) was dissolved in 2.5 liters of water and added to the reactor with slow stirring for 30 minutes and the aqueous layer was separated. The reaction mixture was washed to neutral using hot water at 80 °C. Deodorization of interesterified fats (1-5mbr, 160°C, 2.5 hours).

[0041] The resulting interesterified fat was cooled to 70°C and fed into a margarine crystallizer at a feed rate of 10 kg / hour and into a scraped surface heat exchanger (mutator). The pressure in the variator was adjusted to 8 bar and at 26.2°C the material crystallized to the desired level. Adjust the speed of the mutator to 200 rpm. At a temperature of 26.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com