Medium- and long-chain fatty acid grease rich in 1, 3-dilaurate-palmitic acid triglyceride and preparation and application thereof

A technology of palmitic acid triglyceride and medium and long-chain fatty acids, which is applied in the field of bio-manufacturing of functional oils and fats, can solve the problems of no characteristics of raw edible oils, no site specificity of solid acid catalysts, no richness, etc., and achieve good results. Application value, promotion of body weight gain, effect of low requirements on reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Add 5.0g of palm stearin and 12.12g of lauric acid (molar ratio is 1:10) into a 100ml round bottom flask, fill it with nitrogen, cover with an inversion plug, and place it in a constant temperature water bath shaker at 65°C for a period of time, After the reaction substrate is mixed evenly and in a liquid state, add 1.712g (w / w=10%) of AO IM lipase (provided by Hangzhou Kangyuan Food Technology Co., Ltd.), then fill with nitrogen protection, cover the opening plug, React for 2.5h under the condition of 200r / min.

[0025] (2) After the reaction, remove the immobilized enzyme by filtration, collect the mixed material, use KOH to neutralize the free fatty acid, extract the glyceride with n-hexane, and then distill and remove the n-hexane to obtain the target product. The obtained product was determined by a gas chromatography spectrometer, and the content of 1,3-dilauric acid-2-palmitic acid triglyceride was 39.59%.

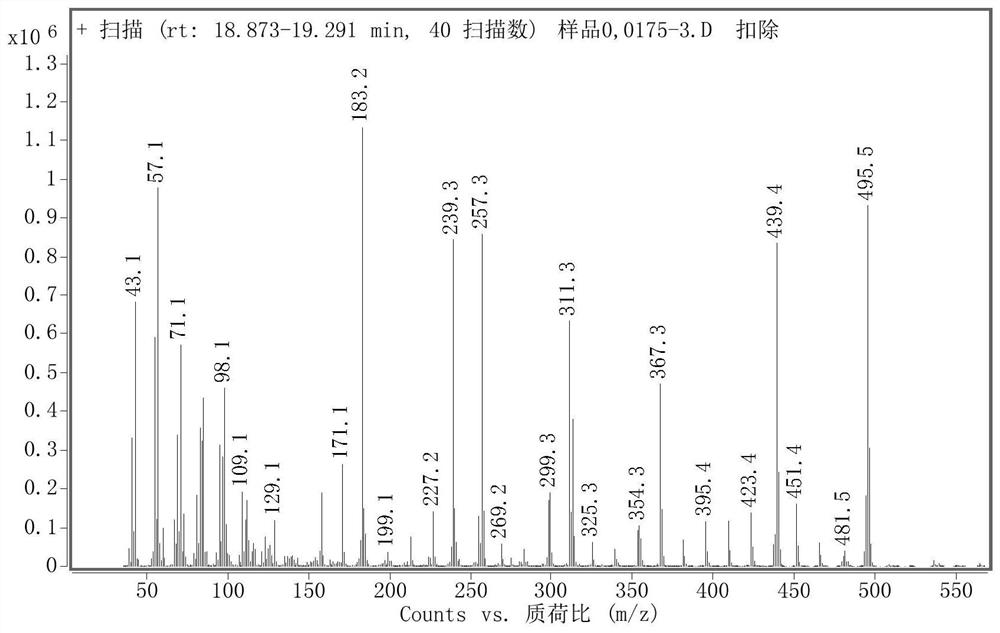

[0026] The mass spectrum of 1,3-dilauric acid-2-pa...

Embodiment 2

[0032] (1) Add 5.0g of palm stearin and 9.7g of lauric acid (molar ratio: 1:8) into a 100ml round bottom flask, fill it with nitrogen, cover with an inversion plug, and place it in a constant temperature water bath shaker at 60°C for a period of time. After the reaction substrates were mixed uniformly and in liquid state, 1.178g RM IM lipase (w / w=8%) was added, then flushed with nitrogen protection, covered with an inversion plug, and reacted at 200r / min for 7h.

[0033] (2) After the reaction, remove the immobilized enzyme by filtration, collect the mixed material, use KOH to neutralize the free fatty acid, extract the glyceride with n-hexane, and then distill and remove the n-hexane to obtain the target product. The obtained product was determined by a gas chromatography spectrometer, and the content of 1,3-dilauric acid-2-palmitic acid triglyceride was 31.76%.

Embodiment 3

[0034] Example 3 (1) Add 5.0 g of palm stearin and 9.7 g of lauric acid (the molar ratio is 1:8) in a 100 ml round bottom flask, fill with nitrogen, cover with an inversion plug, place in a constant temperature water bath shaker at 60°C After a period of time, after the reaction substrate is mixed uniformly and becomes liquid, add 1.178g TL IM lipase (w / w=8%), then flush with nitrogen protection, cover with an inversion plug, and react at 200r / min for 16h.

[0035] (2) After the reaction, remove the immobilized enzyme by filtration, collect the mixed material, use KOH to neutralize the free fatty acid, extract the glyceride with n-hexane, and then distill and remove the n-hexane to obtain the target product. The obtained product was determined by a gas chromatography spectrometer, and the content of 1,3-dilauric acid-2-palmitic acid triglyceride was 24%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com