A method for preparing cigarette filter rods with lyocell tow

A cigarette filter rod and tow technology, which is applied in the field of cigarette filter preparation, can solve the problems that polylactic acid fiber does not show outstanding cigarette tar reduction performance, affects the sensory quality of cigarettes, and has a long process flow, etc., and achieves good biodegradability, The effect of high industrialization realization and mature process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

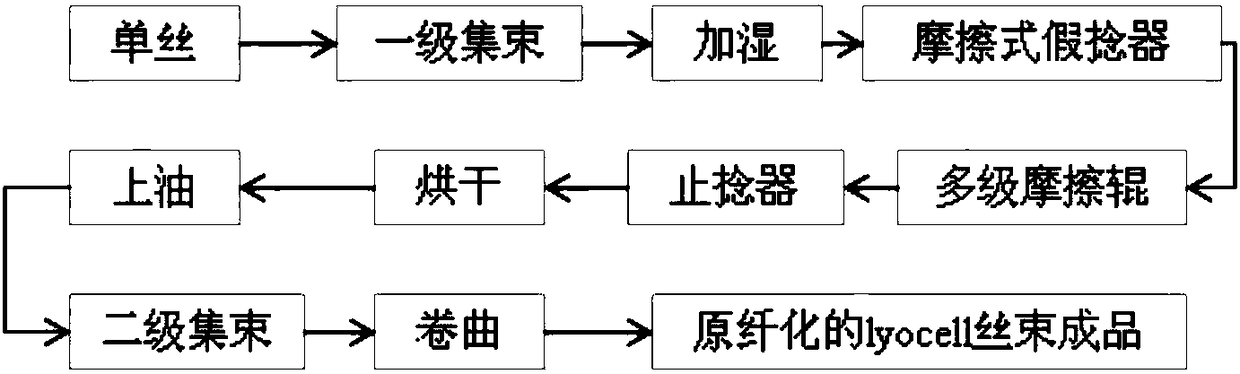

Method used

Image

Examples

Embodiment 1

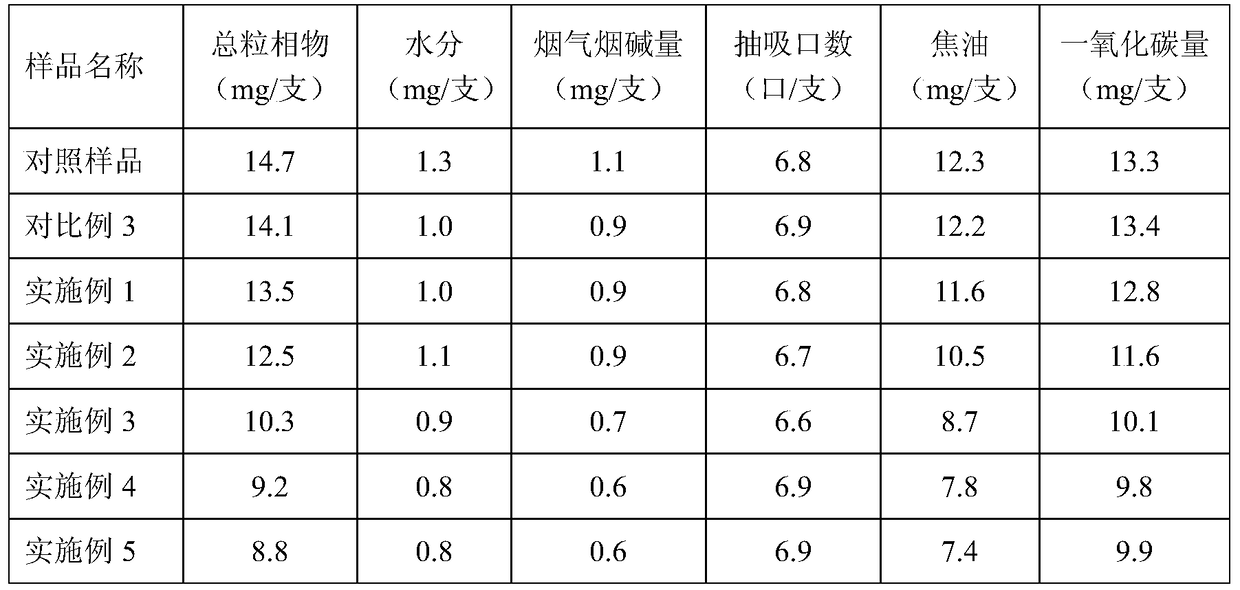

[0023] Adopt the method of embodiment 1 to prepare the lyocell long filament of 3.33dtex linear density of monofilament, the tow of 50dtex of filament linear density is gathered in one stage, through friction disc type false twister and friction roller fibrillation treatment, beating degree is 20 The fibrillated tow of °SR is bundled in two stages to obtain a tow with a linear density of 3.8ktex. After crimping, the cigarette filter rod forming machine is used to produce a cigarette with a length of 100mm, a pressure drop of 2800Pa, and a circumference of 24.0mm filter stick.

Embodiment 2

[0025] Adopt the method of embodiment 1 to prepare the lyocell long filament of monofilament linear density 3.33dtex, the tow of 100dtex is 100dtex by one-stage clustering, through friction disc false twister and friction roller fibrillation treatment, beating degree is 25 The fibrillated tow of °SR is bundled in two stages to obtain a tow with a linear density of 3.8ktex. After crimping, the cigarette filter rod forming machine is used to produce a cigarette with a length of 100mm, a pressure drop of 2800Pa, and a circumference of 24.0mm filter stick.

Embodiment 3

[0027] Adopt the method for embodiment 1 to prepare the lyocell long filament of 3.33dtex linear density of monofilament, the tow of 200dtex of linear density of one-stage clustering, through friction disc type false twister and friction roller fibrillation treatment, beating degree is 32 The fibrillated tow of °SR is bundled in two stages to obtain a tow with a linear density of 3.8ktex. After crimping, the cigarette filter rod forming machine is used to produce a cigarette with a length of 100mm, a pressure drop of 2800Pa, and a circumference of 24.0mm filter stick.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com