Tooth structure of groove (corrugated) paper forming compression roller for cigarettes

A groove and cigarette technology, applied in the direction of machining/deformation, to achieve the effect of clear groove outline, improved coke reduction effect, and simple structure

Pending Publication Date: 2022-06-10

HONGYUN HONGHE TOBACCO (GRP) CO LTD

View PDF14 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the quality of products in the domestic market is uneven, and there are more or less problems such as slot disorder and unclear appearance, which also affect the focus reduction effect.

However, the conventional roll tooth structure requires high dimensional accuracy, high manufacturing cost, and it is easy to chip and damage the tooth during use.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

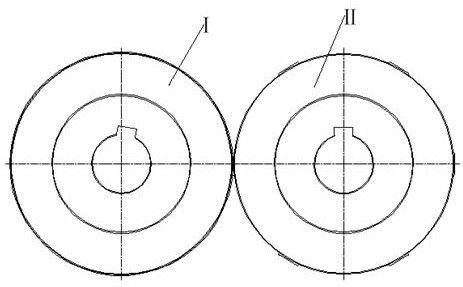

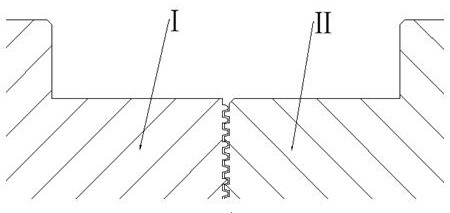

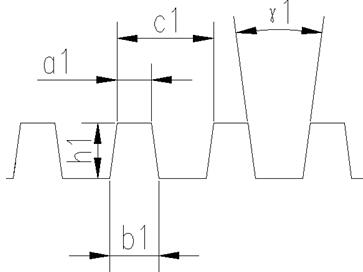

The invention relates to a tooth structure of a compression roller for forming groove (corrugated) paper for cigarettes, which belongs to the field of cigarette filter tip forming machinery and has the advantages that the compression roller is simple in structure, the manufacturing cost is reduced, the tooth height of a manufactured corrugated groove tip rod is 0.4-0.5 mm, the contour of a formed groove is clear and uniform, and the uniformity between corrugated paper and tows is ensured. A uniform air layer can be formed between the corrugated paper and the outer layer cigarette paper, so that the amount of air penetrating into tows can be greatly increased, the air and smoke in the filter tip are uniformly mixed, the concentration of the smoke is reduced, and the tar reduction effect is effectively improved.

Description

technical field [0001] The invention belongs to the field of cigarette filter forming machinery, and in particular relates to a tooth structure of a grooved (corrugated) paper forming pressure roller for cigarettes. Background technique [0002] High-efficiency cigarettes with a corrugated inner ring. The outer layer of the cigarette is cigarette paper, and a layer of corrugated paper is wrapped inside the cigarette paper. Corrugated grooves are formed on the inner ring of the cigarette paper to increase the intake of fresh air, reduce the temperature of the smoke, and reduce the smoke. The harm of gas to the oral cavity and nasal cavity. [0003] The price of imported groove forming paper production equipment remains high. At present, the quality of products in the domestic market is uneven, and there are more or less problems such as slot disorder and unclear appearance, which also affect the focus reduction effect. However, conventional roll teeth require high dimension...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B31F1/20

CPCB31F1/20

Inventor 曹炳强谢伟刘承钧周靖博李季蒙杨俊峰

Owner HONGYUN HONGHE TOBACCO (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com