Mineral water bottle

A mineral water bottle and bottle body technology, applied in packaging, lining/inner coating, coating, etc., can solve the problems of high production cost and complicated process, and achieve the effects of reduced reproduction cost, fast process and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

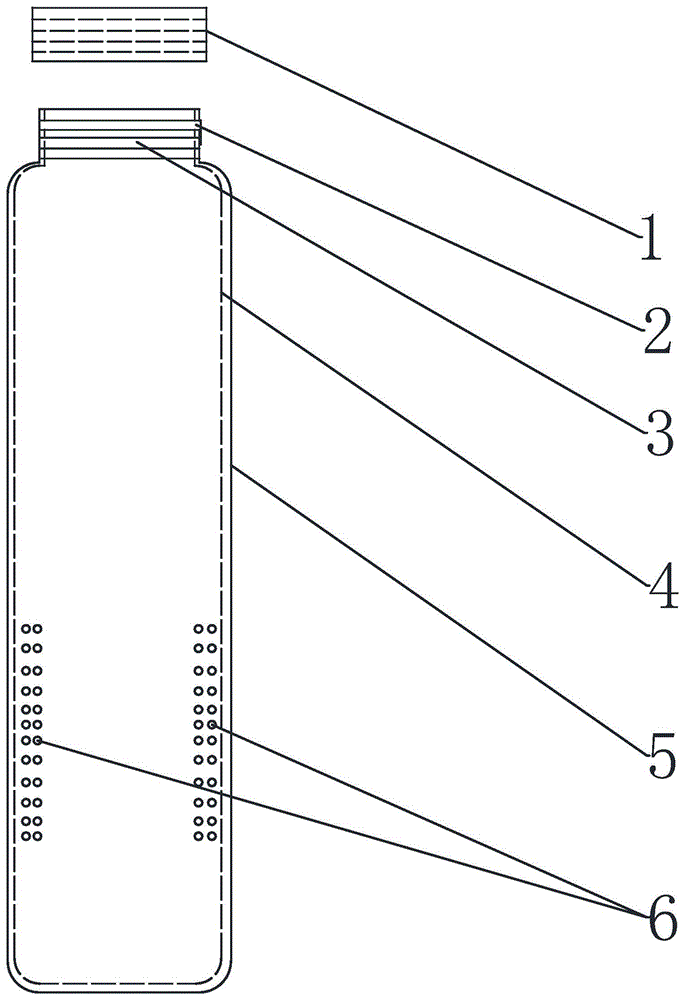

[0017] Such as figure 1 As shown, a mineral water bottle includes a bottle body 6 and a bottle cap 1, the bottle cap 1 and the bottle body 6 are screwed together by a spiral ring or connected by pulling, and the inner wall of the bottle body 6 is closely attached to a layer of film 4, and the film The shape of 4 is identical with bottle body 6 shapes, and the opening of film 4 is fastened the opening of bottle body 6 by tearing tab 3, and film 4 is polyester film 4 or plastic film 4, and bottle body 6 is also provided with antiskid structure 5.

[0018] The principle of the present invention is: by setting a layer of tight film 4 on the inner wall of the bottle body 6, the water storage capacity of the mineral water is not affected. After the water bottle is sterilized, tear off the tear-off sheet 3 that fastens the opening of the bottle body 6, and then pull out the film 4 to be directly reused for mineral water production. The process is simple, the process is fast, and the ...

Embodiment 2

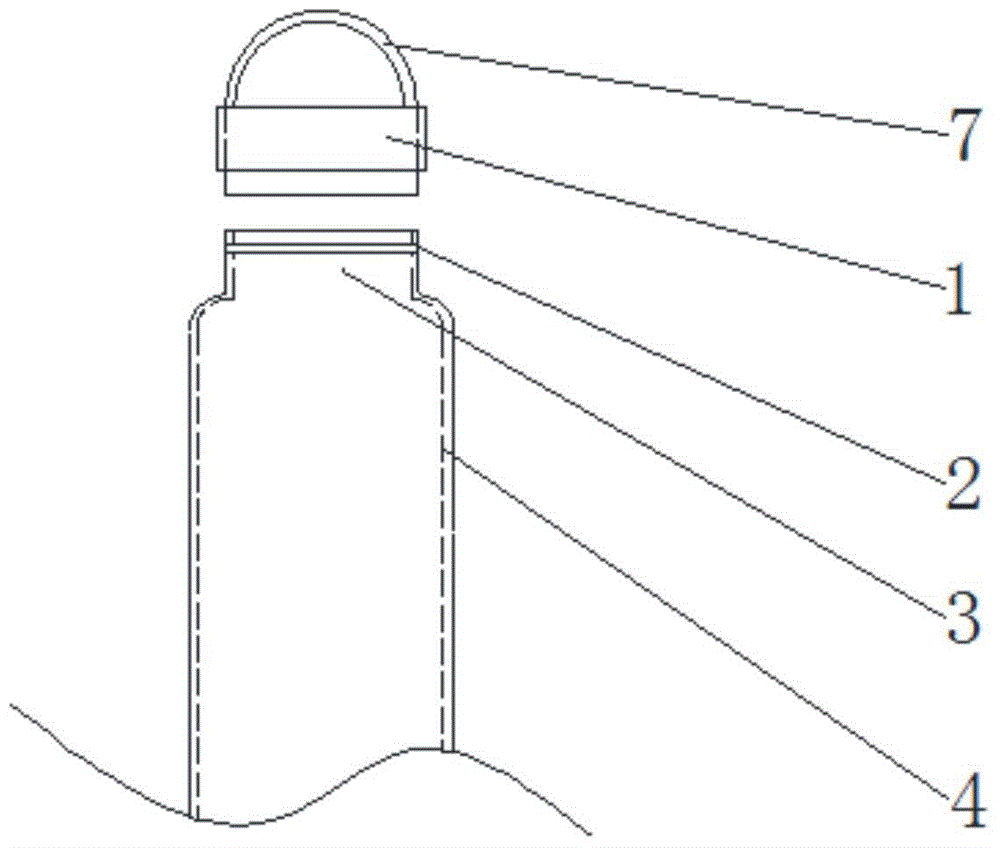

[0020] Such as figure 2 As shown, the principle is the same as that of Example 1, except that the bottle cap 1 is connected to the bottle body 6 by pulling, the top of the bottle cap is provided with a pull ring 7, and the film 4 is a plastic film 4.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap