Variable inlet cross-section oil-gas separator

A technology of oil-gas separator and inlet cross-section, which is applied in the direction of machines/engines, crankcase ventilation, mechanical equipment, etc. It can solve the problems of poor separation effect of the separator, influence of separation efficiency, and uncompact structure, etc., and achieve high oil-gas separation efficiency, Simple structure, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in combination with specific embodiments.

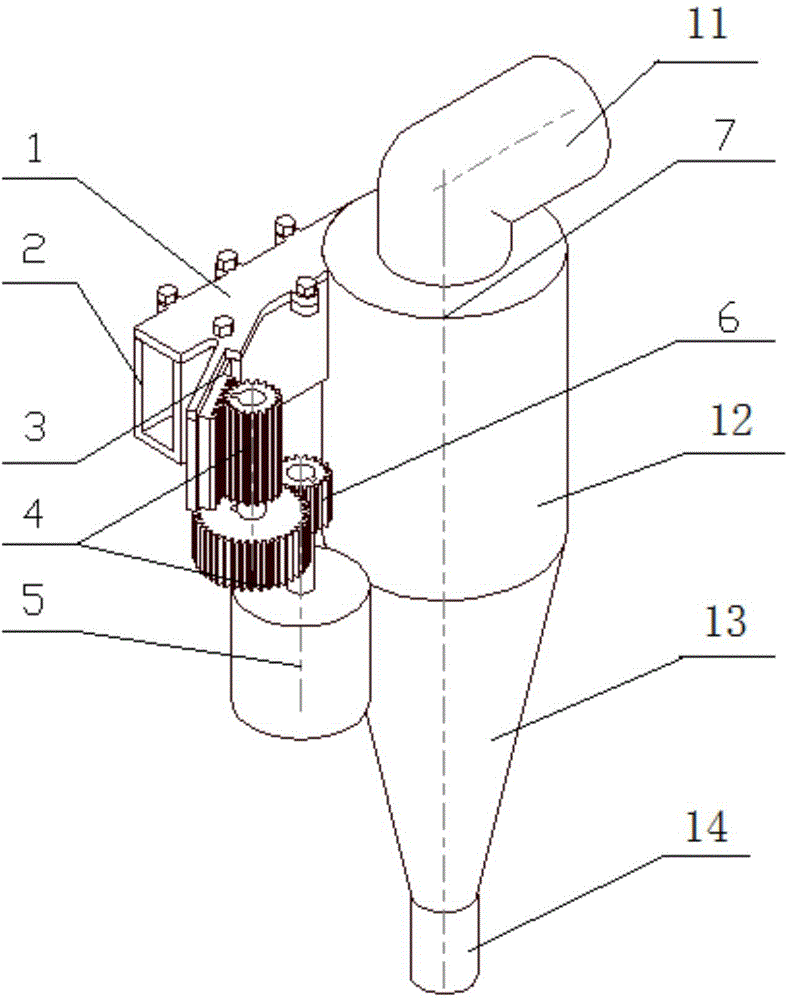

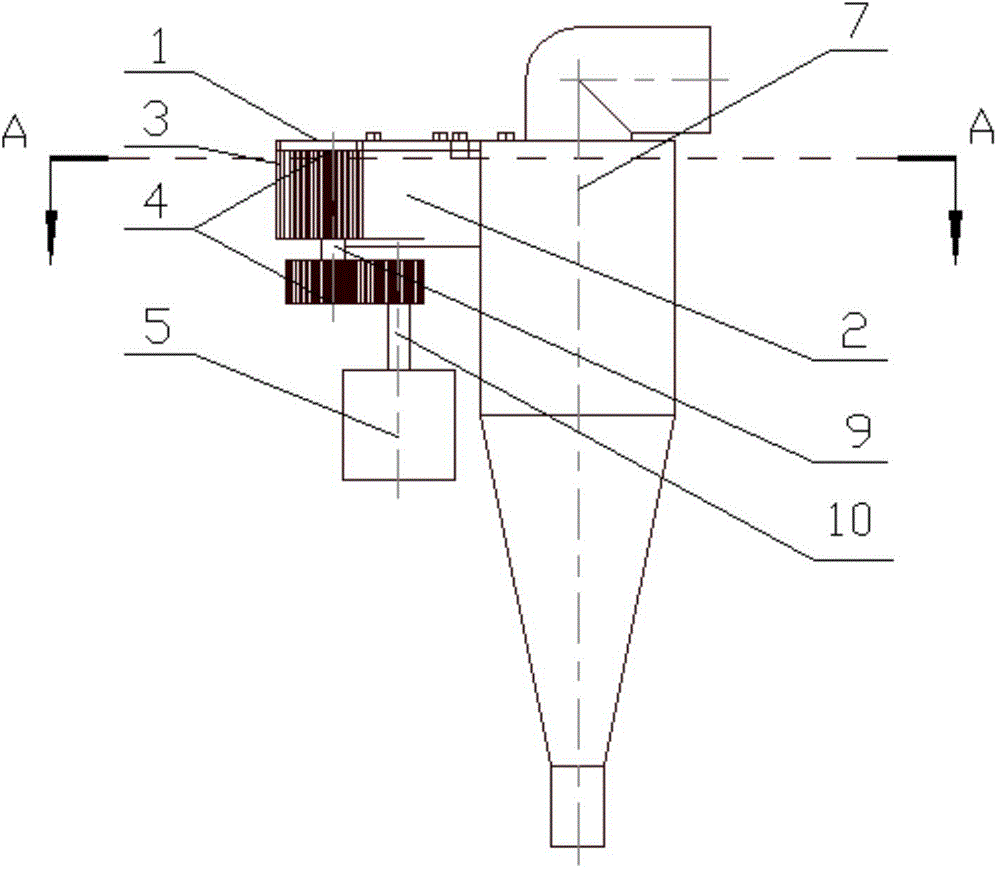

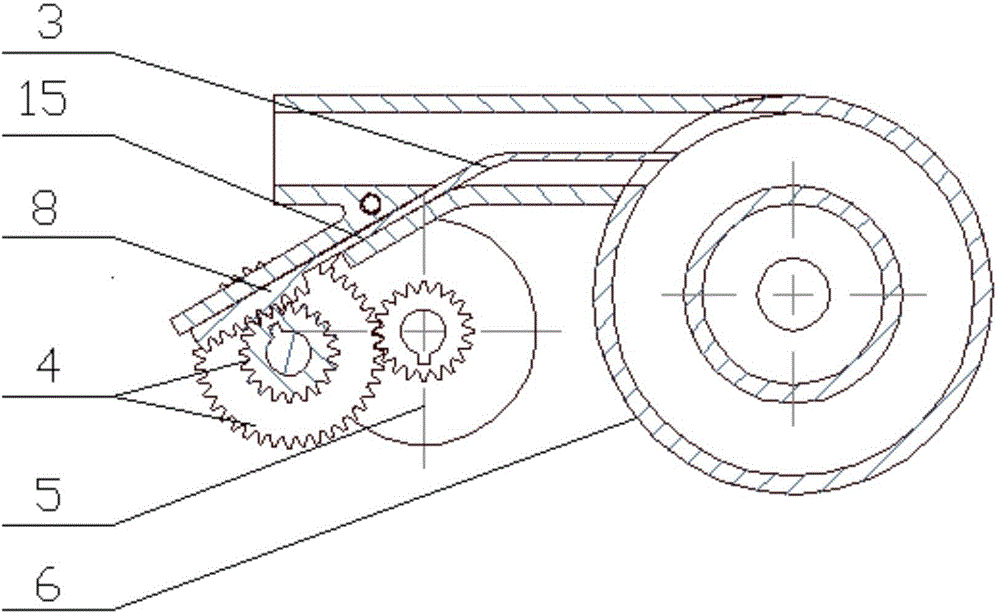

[0021] The invention provides a variable inlet section oil-gas separator, such as figure 1 As shown, it includes the main body 7 of the cyclone oil-gas separator, the intake pipe section 2 with guide grooves, the cover plate of the intake pipe section 1, the sliding plate 3, the reduction gear set 4, the stepping motor 5, and the main body of the cyclone oil-gas separator 7 Including air outlet 11, cylindrical section 12, conical section 13 and oil outlet 14 connected in sequence; stepper motor 5 is provided with stepper motor gear 6; reduction gear set 4 includes upper gear and lower gear connected by gear shaft 9 gears such as image 3 As shown, the end of the sliding piece 3 is a rack 8, the sliding piece 3 is installed in the guide groove 15 of the intake pipe section, and can slide in the intake pipe section 2 along the guide groove, the end of the rack meshes with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com