Method for preparing ferroelectric thin film through magnetron sputtering and ferroelectric thin film

A ferroelectric thin film and magnetron sputtering technology, applied in sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problem of increasing device thermal budget, reducing process efficiency, and damage to device structure and performance, etc. problem, achieve the effect of high residual polarization intensity, solve excessive requirements, and prevent thermal budget

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

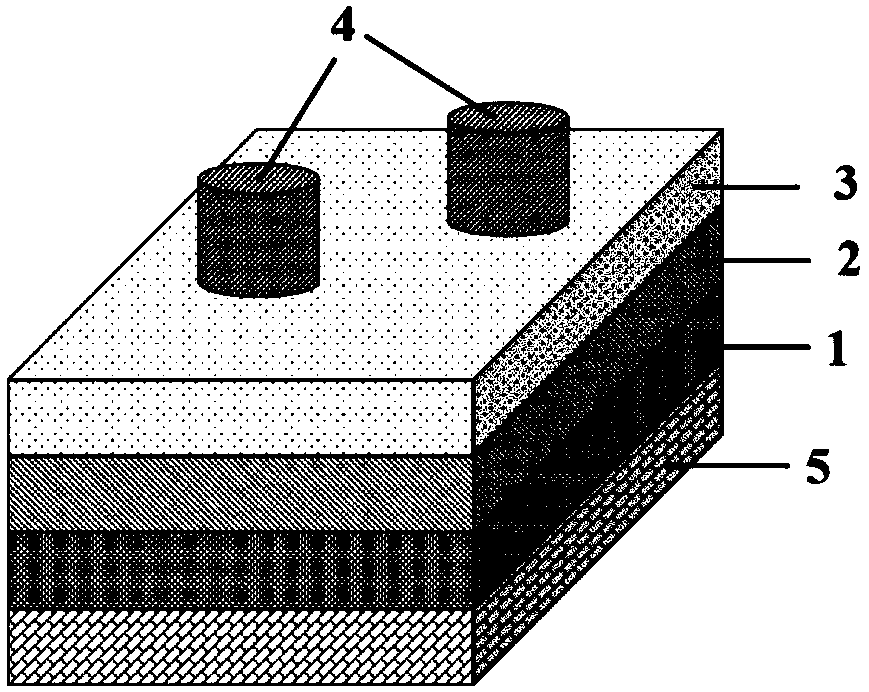

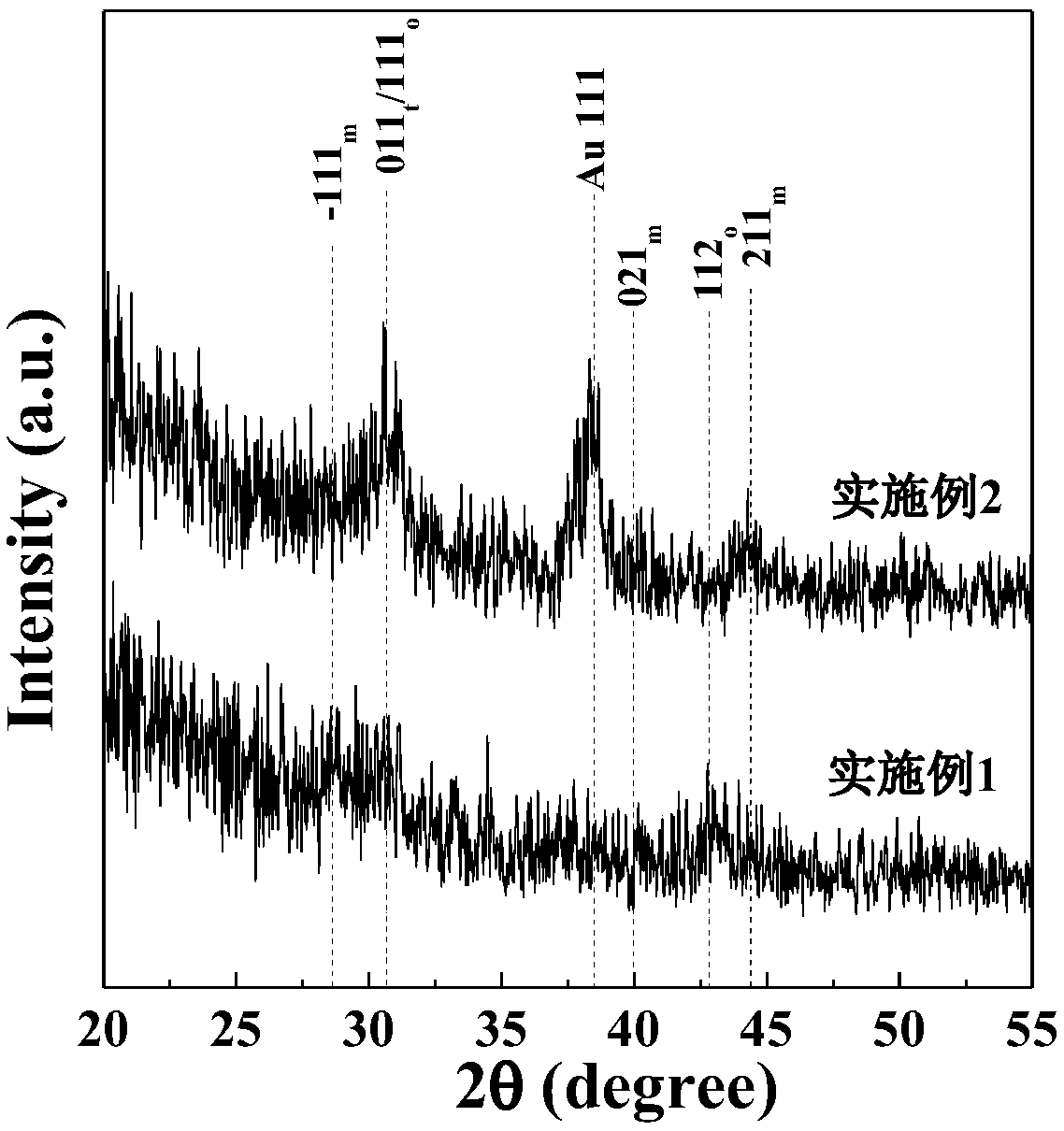

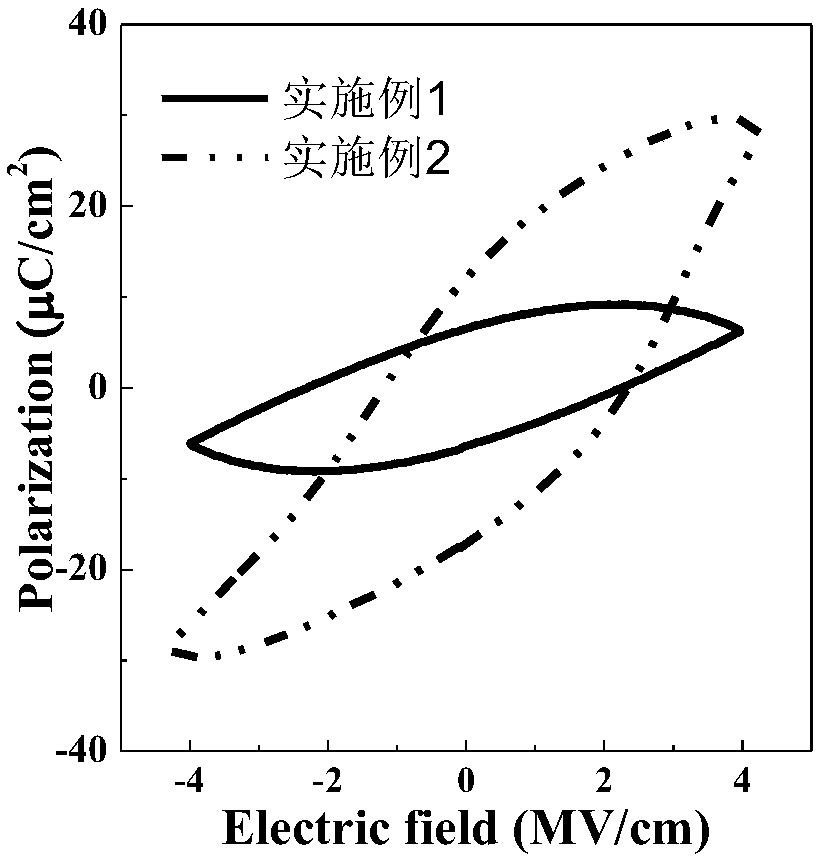

Embodiment 1

[0089] Will n + -Si(100) substrate with 98% H 2 SO 4 With 30% H 2 O 2 The mixing ratio is 5:5 solution cleaning for 10 minutes to remove surface organic matter and particles. After rinsing with deionized water, soak in 1% HF solution for 8s to remove the silicon surface oxide layer. Will clean n + -Si (100) substrate and zirconium-doped hafnium oxide-based ceramic target are placed in the reaction chamber. Adjust the vacuum degree of the reaction chamber, first use a mechanical pump to vacuum the reaction chamber to 10 -2 Pa, then use mechanical pump and molecular pump to simultaneously evacuate the reaction chamber to 10 -5 Pa; Then pass argon and oxygen with a flow ratio of 10:1 into the reaction chamber to adjust the pressure of the reaction chamber to 2Pa and adjust the power to 60W. Under this pressure and power condition, the ignited plasma source ionizes the introduced gas to form an ion current. The ion current is used to bombard the surface of the zirconium-doped hafni...

Embodiment 2

[0092] Will n + -Si(100) substrate with 98% H 2 SO 4 With 30% H 2 O 2 The mixture ratio is 1:1 solution for cleaning for 10 minutes to remove surface organic matter and particles. After rinsing with deionized water, soak in 1% HF solution for 10s to remove the silicon surface oxide layer. Will clean n + -Si(100) substrate and zirconium-doped hafnium oxide-based ceramic target are placed in the reaction chamber, and the zirconium-doped hafnium oxide-based ceramic target is adjusted to n + -Si (100) substrate distance to 55mm. Adjust the vacuum degree of the reaction chamber, first use a mechanical pump to vacuum the reaction chamber to 10 -2 Pa, then use mechanical pump and molecular pump to simultaneously evacuate the reaction chamber to 10 -6 Pa; then pass pure argon into the reaction chamber to adjust the pressure of the reaction chamber to 2Pa and adjust the power to 60W. Under this pressure and power condition, the ignited plasma source ionizes the introduced gas to form an ...

Embodiment 3

[0095] Will n + -Si(100) substrate with 98% H 2 SO 4 With 30% H 2 O 2 The mixed solution is cleaned for 10 minutes to remove surface organic matter and particles. After rinsing with deionized water, it is soaked in 1% HF solution for 10s to remove the silicon surface oxide layer. Will clean n + -Si(100) substrate is placed in the reaction chamber to adjust the zirconium-doped hafnium oxide-based ceramic target and n + -Si (100) substrate distance to 55mm. Adjust the vacuum degree of the reaction chamber, first use a mechanical pump to vacuum the reaction chamber to 10 -2 Pa, then use mechanical pump and molecular pump to simultaneously evacuate the reaction chamber to 10 -6 Pa; then pass pure argon into the reaction chamber to adjust the pressure of the reaction chamber to 2Pa and adjust the power to 50W. Under this pressure and power condition, the ignited plasma source ionizes the introduced gas to form an ion current. The ion current is used to bombard the surface of the zir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com