A heavy-duty connector for internal and external wiring of electrical panels

A technology of external wiring and electrical screen, applied in the direction of two-part connection device, connection, electrical components, etc., can solve the problems of troublesome disconnection, heavy workload, high wiring error rate, and ensure anti-interference ability, convenient fixation, and disassembly. Convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

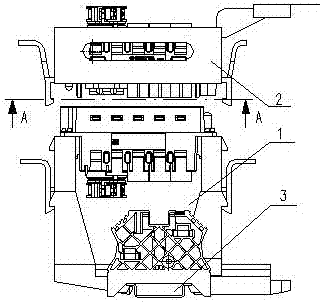

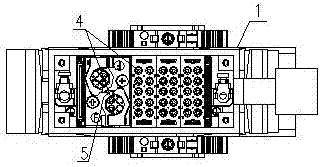

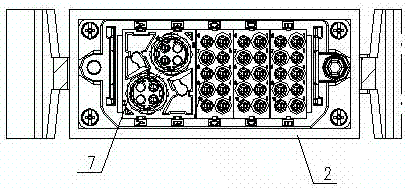

[0022] like figure 1 , 2 , 3 and 4 are structural schematic diagrams of the present invention, a heavy-duty connector for realizing internal and external wiring of the electric screen cabinet, including a plug 1 and a socket 2, the plug 1 is provided with a base plate 3, and the base plate 3 is fixed in the electrical cabinet On the guide rail, there are male pins 4 and male pin sleeves 5 inside the plug 1, male pins 4 are arranged inside the male pin sleeve 5, the rear ends of the male pins 4 are connected to wires, and the rear ends of the male pin sleeves 5 are The terminal is connected to the shielding layer of the shielded wire. The socket 2 is provided with a female plug sleeve 6 and a female pin sleeve 7 inside. The female pin sleeve 7 is provided with a female plug sleeve 6. The rear end of the needle sleeve 7 is connected to the shielding layer of the shielding wire. The plug 1 and the socket 2 are connected through the male ferrule frame 8 and the female ferrule fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com