Fiber laser output head having light beam focusing characteristic and power monitoring function

A fiber laser and power monitoring technology, which is applied in the direction of lasers, laser components, laser components, etc., can solve problems such as optical damage, fiber end face reflection, and excessive working power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

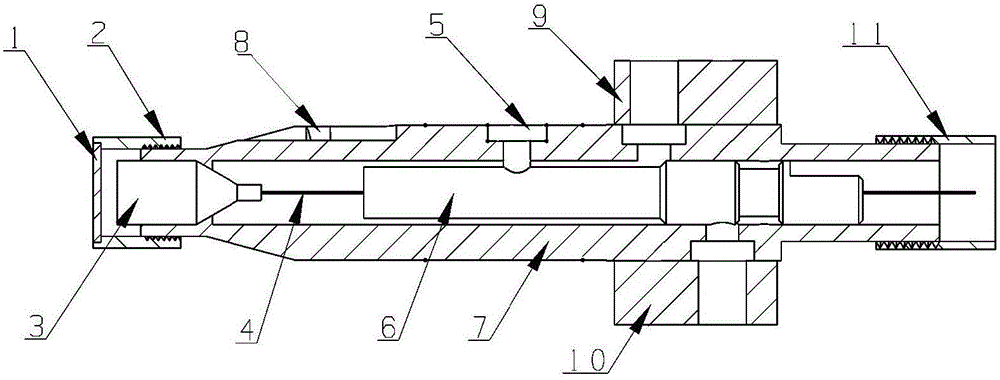

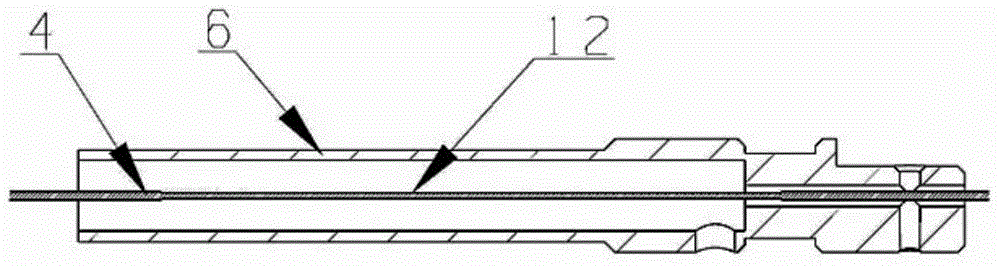

[0011] like figure 1 and figure 2 As shown, a fiber laser output head with beam focusing characteristics and power monitoring function, the fiber laser output head is composed of a laser power transmission device and an external packaging device, the laser power transmission device includes a beam focusing system, a quartz end cap 3, The optical fiber 4 and the mode stripper 12, the external packaging device includes a photoelectric monitoring system 5, a water flow guide tube 6, a metal shell 7, a clamping lock 8, a water inlet connector 9, a water outlet connector 10, and a metal optical cable connector 11; the beam focusing system includes Focus lens 1, focus adjustment device 2.

[0012] The focus lens 1 is inlaid at the end of the focus adjustment device 2 .

[0013] One end of the metal cylinder 7 is fixed to the inner wall of the focus adjustment device 2 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com