A kind of spicy sauce for cold dishes and its preparation process

A technology for sauces and cold dishes, which is applied to the field of spicy sauce and its preparation technology, can solve the problems of complex seasoning operations for cold dishes, difficult to clean tableware, poor taste, etc., and achieves refreshing and non-greasy taste, easy cleaning, and simple use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

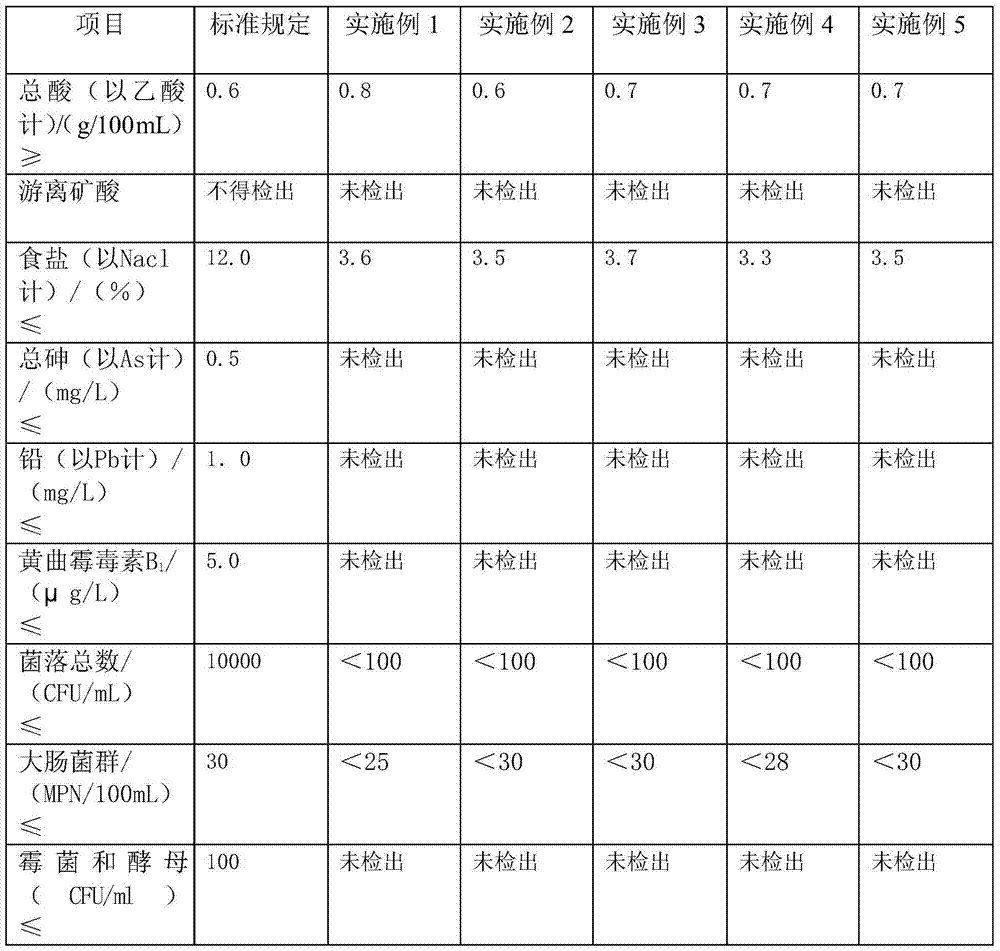

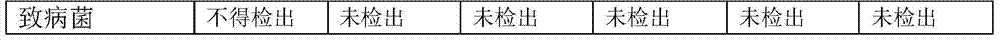

Examples

Embodiment 1

[0022] A spicy sauce for cold dishes, the raw material composition of the spicy sauce includes: by weight percentage, 52% of pure water, 11% of rice vinegar, 1.8% of edible lactic acid, 20% of brewed soy sauce, 8% of salt %, white sugar 5%, monosodium glutamate 0.7%, nucleotide disodium 0.1%, sodium carboxymethyl cellulose 0.063%, xanthan gum 0.097%, potassium sorbate 0.1%, chicken paste 0.5%, black bean paste 0.42 %, water-soluble pepper oleoresin 0.06%, water-soluble capsicum essence 0.06%, water-soluble capsanthin 0.07%, water-soluble sesame oil essence 0.03%.

Embodiment 2

[0024] A spicy sauce for cold dishes, the composition of the raw materials of the spicy sauce includes: in weight percentage, 56% of pure water, 9% of rice vinegar, 1.5% of edible lactic acid, 18% of brewed soy sauce, 10% of salt %, white sugar 3%, monosodium glutamate 0.8%, nucleotide disodium 0.06%, sodium carboxymethyl cellulose 0.067%, xanthan gum 0.093%, potassium sorbate 0.07%, chicken paste 0.8%, soy meat paste 0.39% %, water-soluble pepper oleoresin 0.07%, water-soluble capsicum essence 0.07%, water-soluble capsanthin 0.07%, water-soluble sesame oil essence 0.01%.

Embodiment 3

[0026] A kind of spicy sauce for cold dishes, the raw material composition of described spicy sauce comprises: by weight percentage, pure water 54.2%, rice vinegar 10%, edible lactic acid 1.7%, brewed soy sauce 19%, salt 9% %, white sugar 4%, monosodium glutamate 0.6%, nucleotide disodium 0.08%, sodium carboxymethyl cellulose 0.065%, xanthan gum 0.095%, potassium sorbate 0.08%, chicken paste 0.6%, soy meat paste 0.41 %, water-soluble pepper oleoresin 0.05%, water-soluble capsicum essence 0.05%, water-soluble capsanthin 0.05%, water-soluble sesame oil essence 0.02%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com