A slide rail assembly machine

An assembly machine and slide rail technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low installation efficiency and inconvenient processing operations, and achieve high installation efficiency, saving manufacturing costs, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

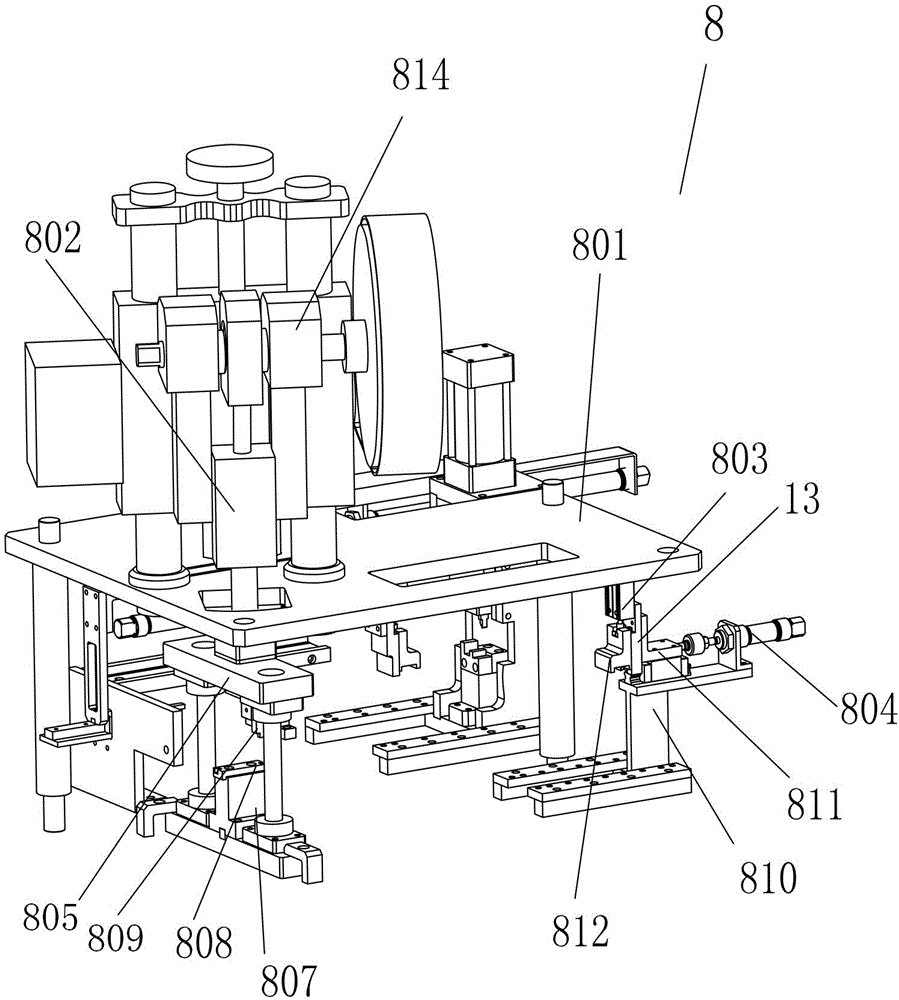

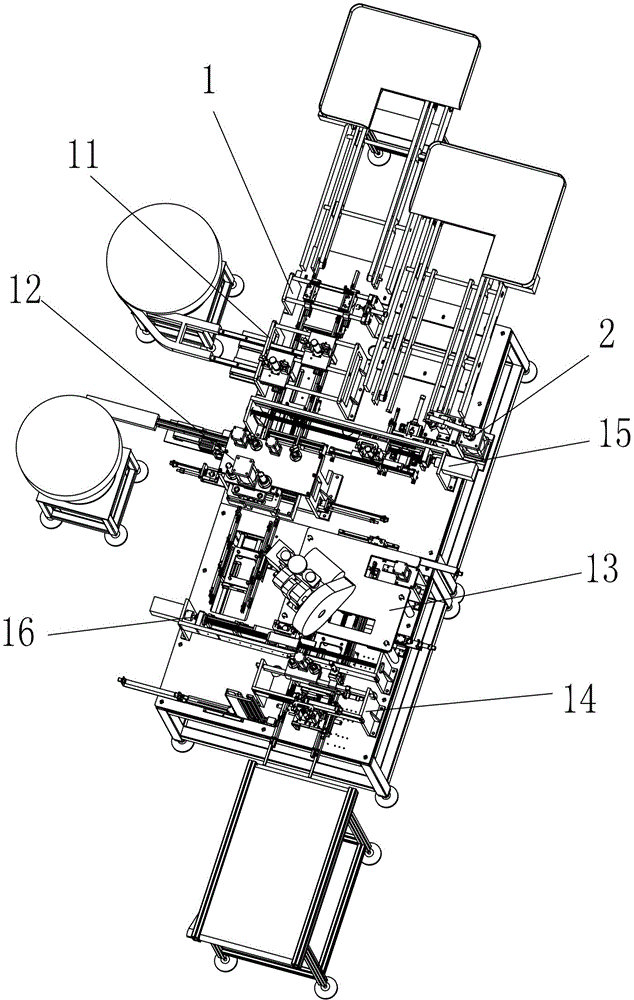

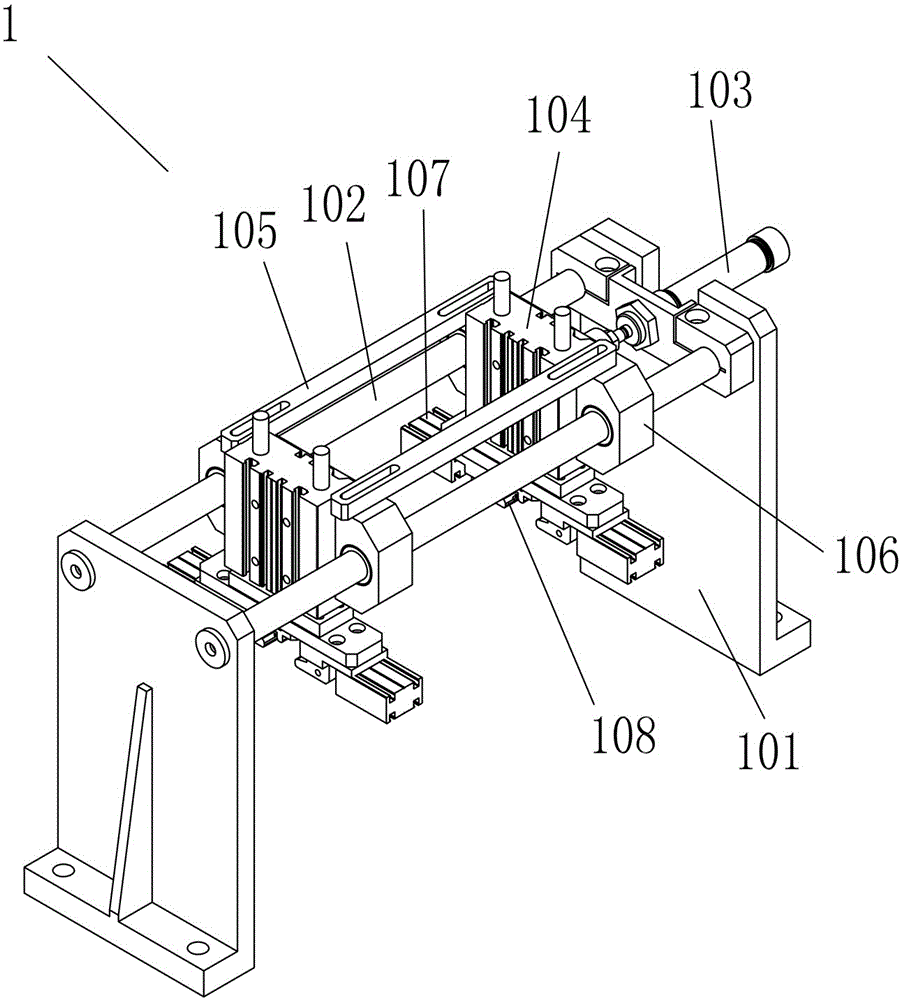

[0067] as reference Figure 1 to Figure 14 Describe a slide rail assembly machine according to an embodiment of the present invention, which includes an oiling mechanism 1 with a middle rail on one side of the conveyor table for oiling. On the side of the mechanism 11, there is a bumping mechanism 2 for dotting the middle rail. Between the bead nesting mechanism 11 and the bumping mechanism 2, there is a movable rail for sending the movable rail to the rear end of the bead nesting mechanism 11 and intersecting with the middle rail. The socketed first guide rail conveyor 15, the rear end of the bead nest mechanism 11 is also provided with the first mixed installation mechanism 12 for hitting side points and installing the middle rail sliding bead parts, and the first mixed installation mechanism 12 side is provided with for The second hybrid installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com