Welding equipment for oil plug seat of automobile axle housing

A technology of welding equipment and screw plug seat, which is applied in the field of welding equipment for automotive axle housing refueling screw plug seat, which can solve the problems of insufficient weld width, unfixed workpiece, easy-to-shake solder joints, etc., so as to improve welding quality and weld shape Beautiful and avoid the effect of welding porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

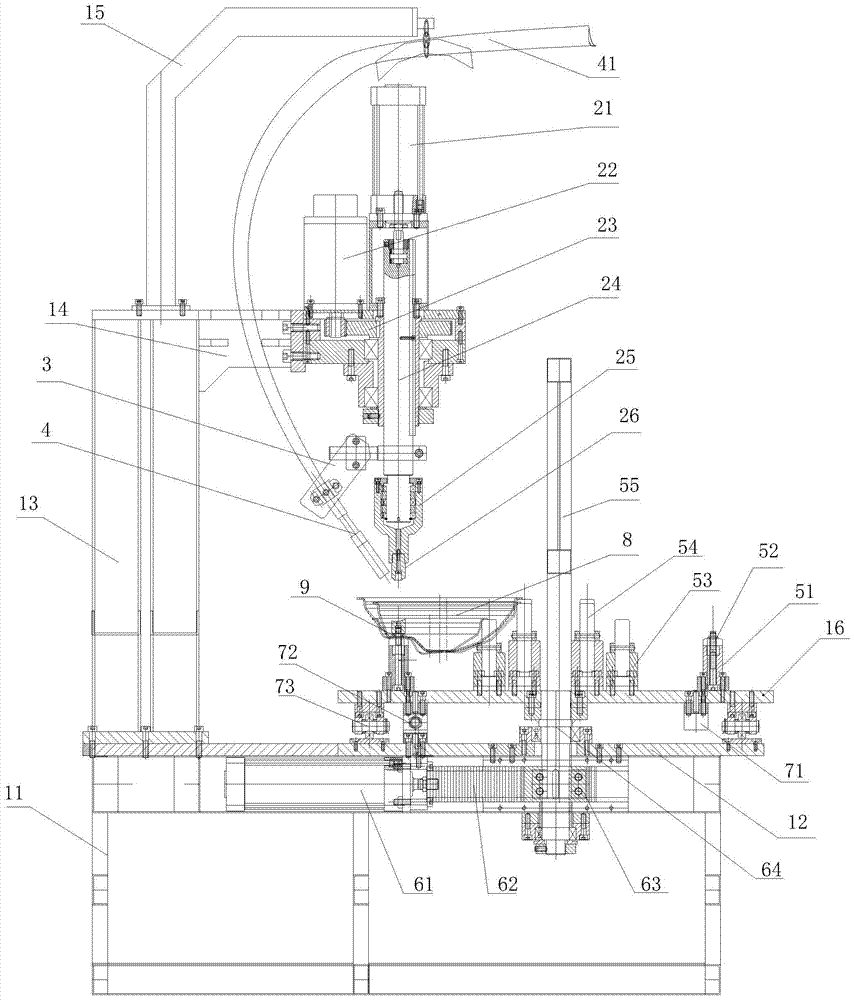

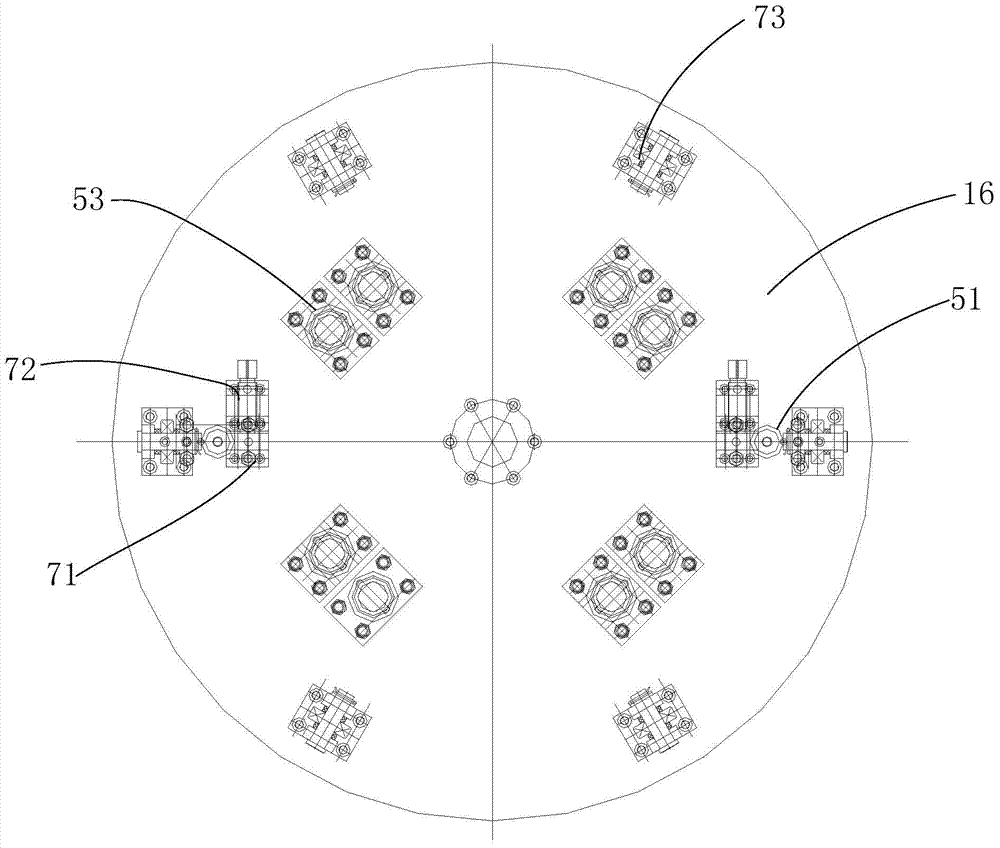

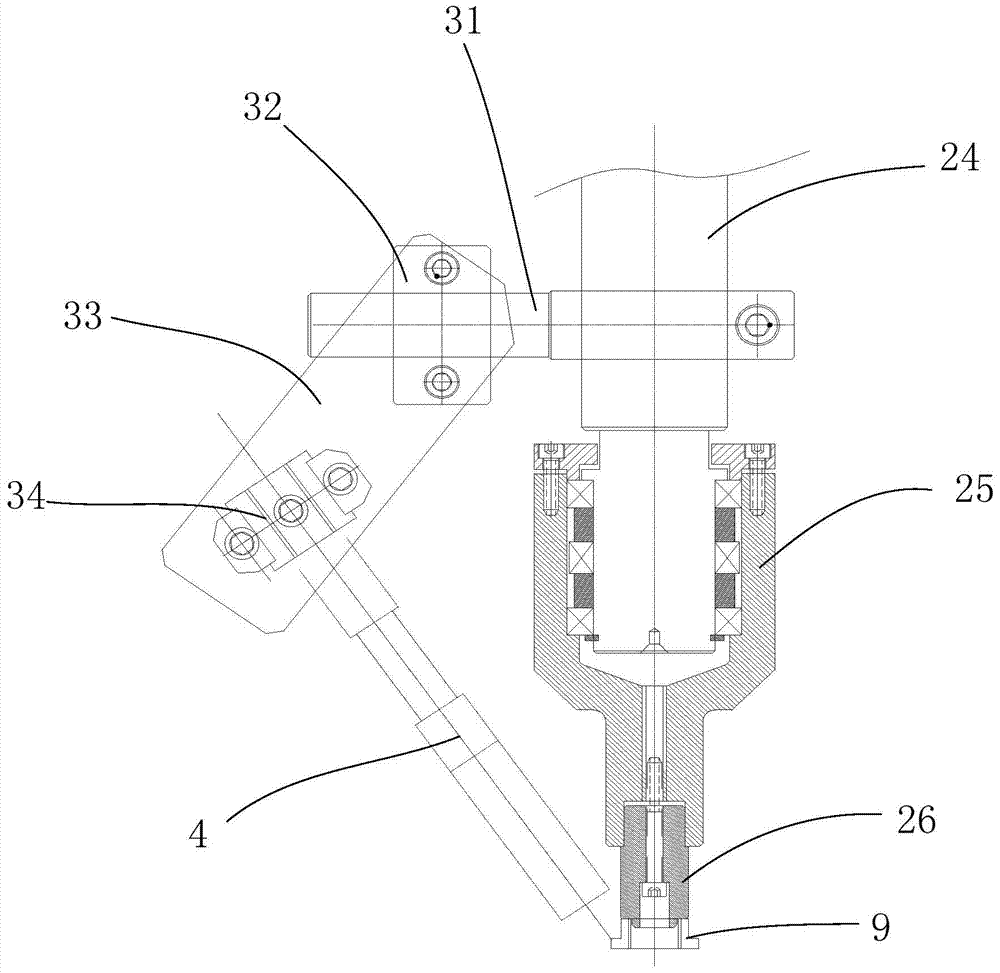

[0058] Such as figure 1 As shown, the present invention provides a kind of welding equipment for automobile axle housing refueling screw plug seat, comprising a base 12 installed on a frame 11, a welding support 13 and a workbench 16 are installed on the base 12, and a rear end is installed on the workbench 16. The bridge cover positioning mechanism, the welding support 13 is equipped with an up and down propulsion mechanism, the up and down propulsion mechanism is equipped with a pressing mechanism and a welding torch 4, the pressing mechanism and the welding torch 4 are located above the workbench 16, and the up and down propulsion mechanism is installed through the support seat 14 On the welding support 13, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com