A kind of method for making imitation wood grain texture cement prefabricated products

A technology of imitating wood grain and prefabricated products, which is applied to the production of imitated wood grain textured cement prefabricated products, the production of cement prefabricated plank boards, and the field of cement prefabricated products. It can solve the problems of short service life, non-slip resistance in rainy days, and low bearing strength. Achieve good results, reduce usage, and reduce felling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

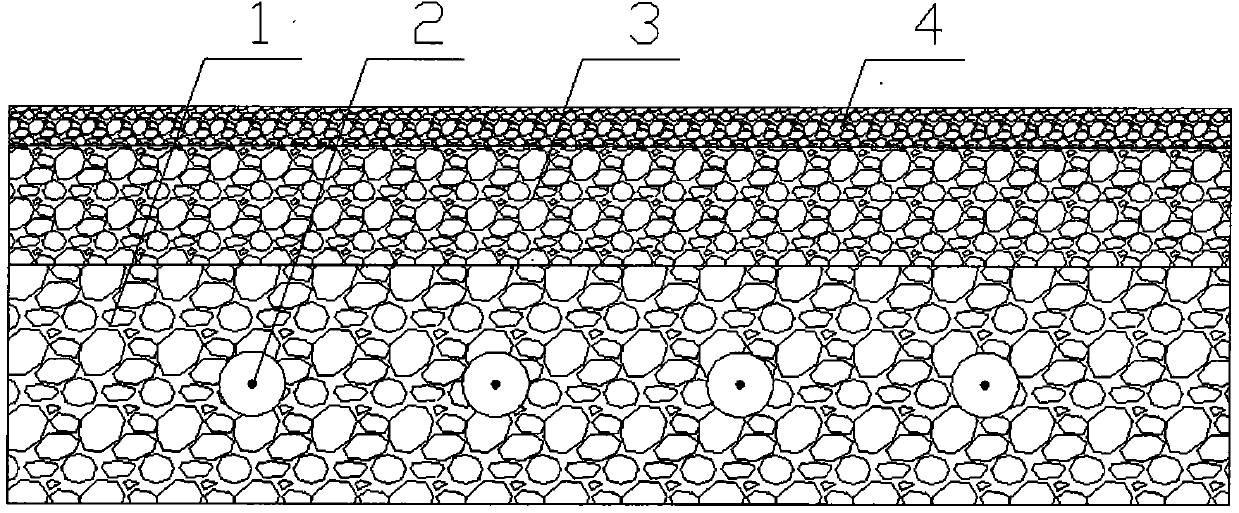

[0014] Taking imitation wood-grain plank board as an example, the specific embodiment of the present invention is described below. The method of imitating wood-grain texture cement prefabricated by wood mainly includes three steps: the method includes using silica gel to extract the wood-grain texture surface of the wood board to make a mold The high-strength anti-seepage cement concrete layer 1 is made; when the cement concrete layer 1 is not dry, the wood grain texture mold molded by silica gel is placed on the cement concrete layer 1 by pressure or vibration with a machine or manually, and the wood grain texture is placed on the cement concrete layer 1. When the cement concrete layer 1 is not dry, the cement concrete layer 1 is subjected to setting treatment, and the imitation wood grain cement concrete layer 1 is placed in a cool place to dry naturally or by heating.

[0015] Choose wood boards with good real wood grain, fix them well, and dry them in shape. Brush the dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com