Carbon fiber cloth winding forming device for small-diameter shaft products and method for processing shaft products

A carbon fiber cloth, winding forming technology, which is applied in the field of small diameter shaft products carbon fiber cloth winding forming device and processing shaft products, can solve the problems of fracture, bending deformation of the winding mechanism mandrel, etc., and achieves short production cycle, easy loading and unloading, Simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

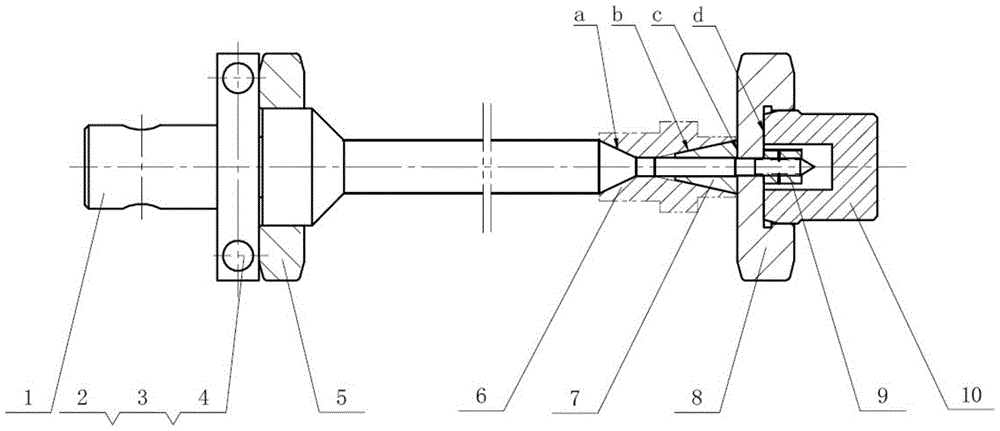

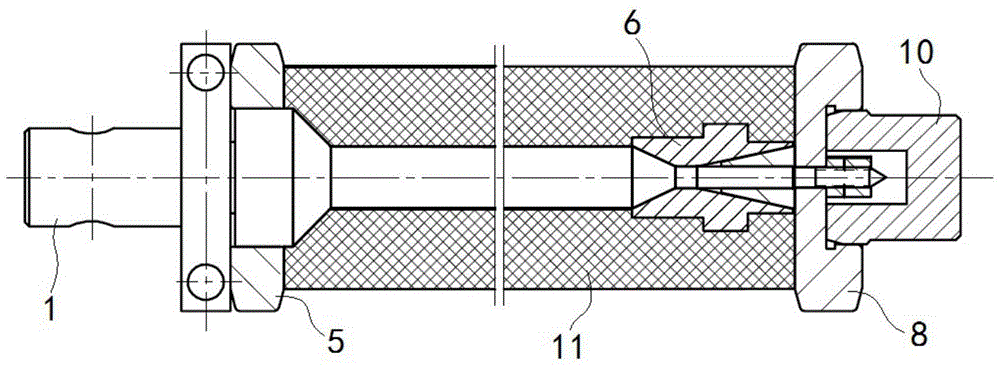

[0038] Attached to a carbon fiber cloth winding and forming device for small-diameter shaft products figure 1 , The device is mainly composed of mandrel 1, snap rings 2, 3, screws 4, front baffle 5, throat lining 6, bushing 7, back baffle 8, nut 9, sleeve 10.

[0039] When working, clamp the mandrel 1 of the product contour forming part on the lathe; the left end of the mandrel is fitted with the front baffle 5 of the demoulding part; the first snap ring 2, the second snap ring 3 and the screw 4 are stuck on the big end of the mandrel It is used to locate the front baffle so that parts can be quickly disassembled during demoulding; the axial force transmission mechanism placed at the top of the lathe is throat bushing 6, bushing 7, rear baffle 8, and sleeve 10; the lock placed at the end of the mandrel Tighten the nut 9.

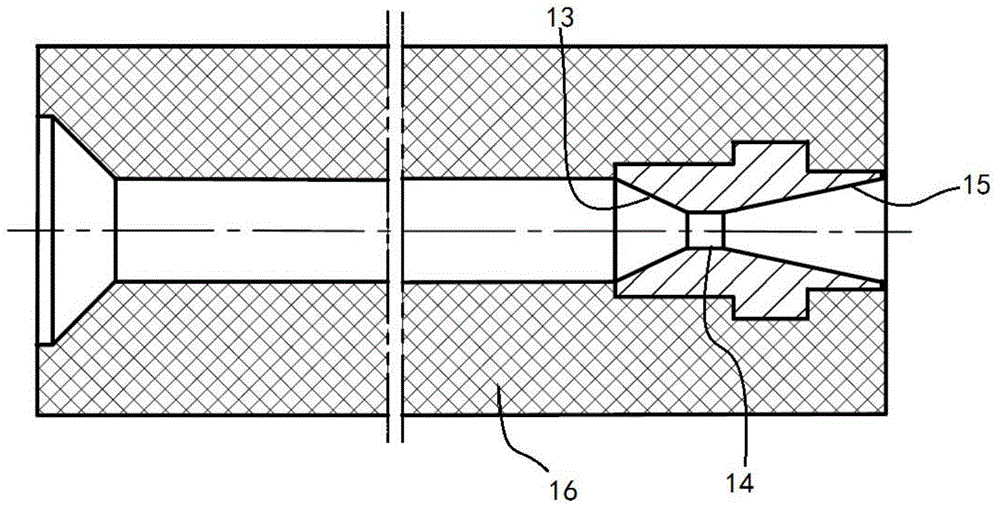

[0040] The mandrel 1 is located between the front baffle 5 and the rear baffle 8 and is a carbon fiber cloth winding section; the side of the carbon fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com