Foam plastic combined stripping and transecting machine

A technology of cross-cutting machine and sponge, which is applied in the directions of sending objects, thin material processing, transportation and packaging, etc., to achieve the effect of compact structure, complete functions, convenient disassembly, assembly, maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

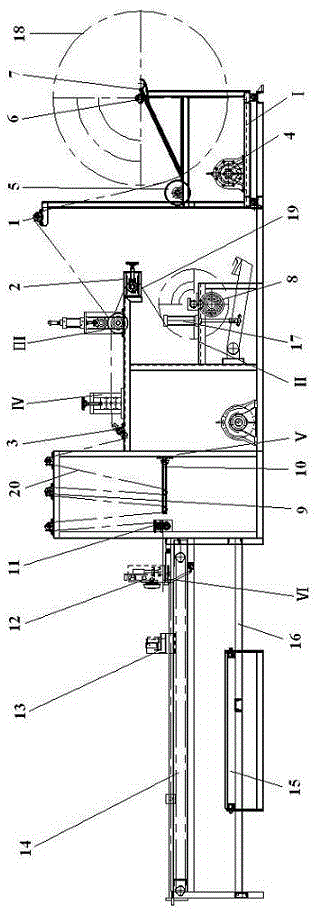

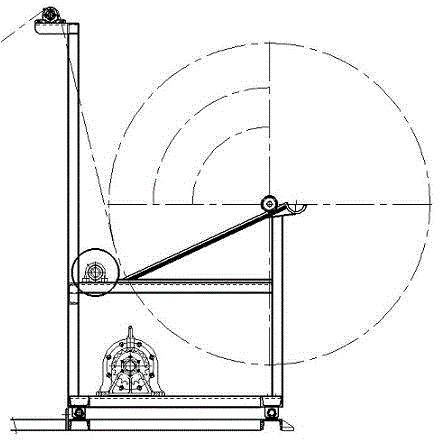

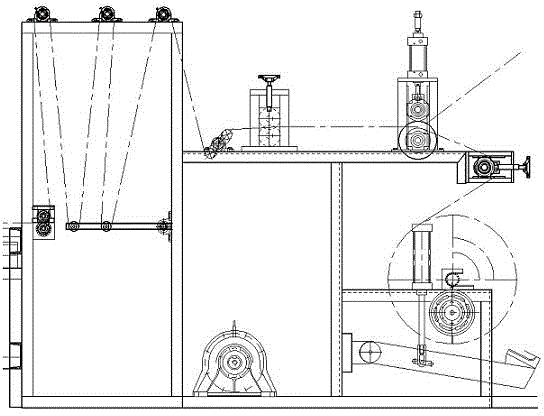

[0021] Such as figure 1 — Figure 4 , a sponge composite slitting and cross cutting machine, including a frame, on which there are sponge active unwinding device Ⅰ, release paper automatic feeding passive unwinding device Ⅱ, heating composite device Ⅲ, and multi-knife slitting device Ⅳ. Material storage rack Ⅴ, material pulling cross-cutting device Ⅵ and discharging traversing supporting plate 15. A sponge coil traction and conveying device 1 is provided on the frame at the rear end of the sponge active unwinding device I, and a drive cylinder 17 and a brake 8 are provided on the frame of the passive unwinding device II for automatic feeding of release paper. The heating compound device III is set on the upper frame of the release paper automatic feeding passive unwinding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com