Method for increasing formation bearing pressure during drilling plugging

A technology of pressure bearing capacity and formation, applied in the field of leakage plugging materials, can solve the problems of difficulty in bridging, easy to crush and deform, and difficult to form, and achieve the effect of easy bridging and improvement of pressure bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 The preparation of hard type plugging material

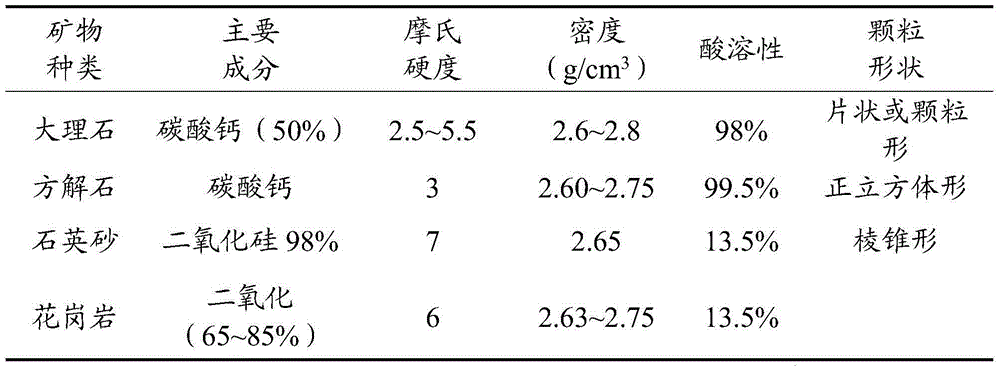

[0041] (1) Mix 70-80 parts of calcite, 0-10 parts of marble, 0-10 parts of quartz and 0-10 parts of granite to obtain rigid plugging agent GFD;

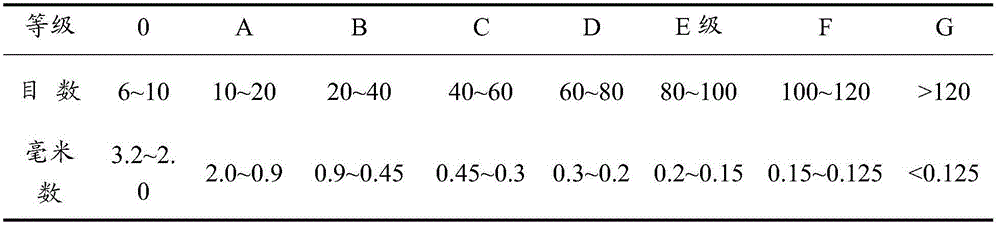

[0042] (2) Grind the rigid plugging agent GFD into 0, A-G8 particle size grades, as shown in Table 2 below:

[0043] Table 2 Level Classification

[0044]

Embodiment 2

[0045] The preparation of embodiment 2 auxiliary materials

[0046] Walnut shells, ultra-fine calcium carbonate and mica were respectively ground into various particle size grades as shown in Table 2 in Example 1 above.

Embodiment 3

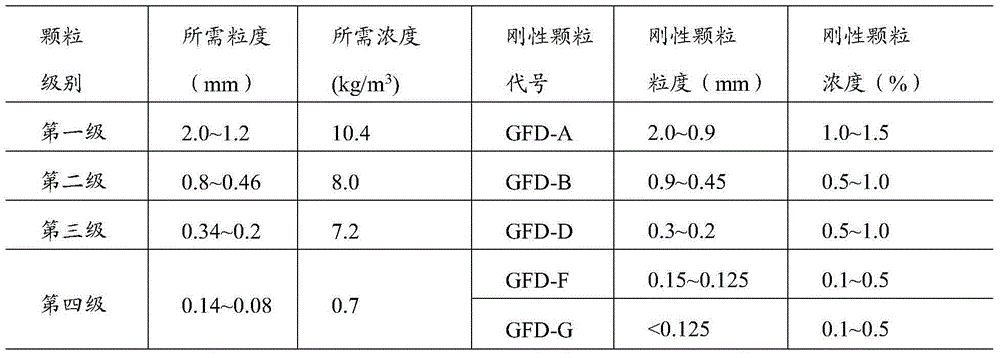

[0047] The establishment of embodiment 3 optimal ratio relation table

[0048] 1. Experimental instruments: improved DL plugging tester, HTHP water loss tester, etc.

[0049] Use the DL-type plugging instrument to modify, remove the lower marble, and add a stainless steel crack mold, where the crack on the mold is wedge-shaped to simulate the crack. According to the stratum data statistics, the fracture opening in the stratum is selected as 0.5, 1, 1.5, 2, 3mm. If the fracture opening is greater than 3 mm, the leakage rate is too high, and the wellhead is generally lost. For cracks smaller than 0.5mm, the phenomenon is not obvious in indoor experiments.

[0050] 2. Test drugs:

[0051] For base slurry with 4% bentonite content, add 0.1% NaOH, 0.05% KPAM, 4% SMC, 4% SMP-1, 0.5% LS-2, 4% FRH, 2% Fk-10, 0.3% SP-80, The density is 1.60g / cm 3 .

[0052] 3. Subjects

[0053]The experiment of improving the pressure bearing capacity of the formation with pressure plugging in We...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com