High-pressure oil pump mounting seat with sound insulation structure

A high-pressure oil pump and mounting seat technology, which is applied to fuel injection devices, charging systems, and fuel injection pumps with noise reduction measures, can solve problems affecting the NVH performance of the whole machine, and achieve the effect of improving NVH performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

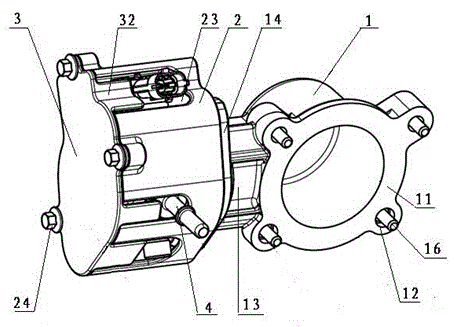

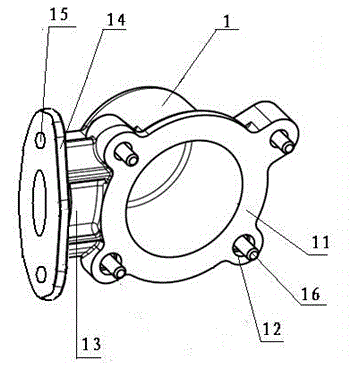

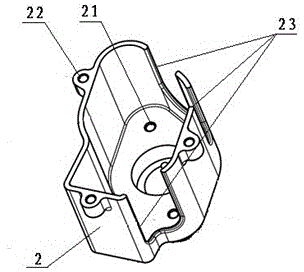

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] see Figure 1 to Figure 5 A high-pressure oil pump mounting seat with a sound-insulating structure is shown, including a mounting seat body. The mounting seat body consists of a high-pressure oil pump cam chamber 1, a first flange 11 connected to the lower end of the high-pressure oil pump cam chamber, and a high-pressure oil pump. The support member 13 on the side wall of the cam chamber and the second flange 14 connected with the support member are composed of four first bolt holes 12 on the first flange 11, and four first bolt holes 12 on the second flange 14. There are two second bolt holes 15, and its outstanding substantive features are:

[0021] It also includes a soundproof box body 2 connected to the second flange 14 of the mounting seat body, and a sealing cover 3 connected to the soundproof box body; the bottom of the soundproof box body 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com