An Ellipse Spherical Plug Type Inlet Valve for Reciprocating Compressor

An elliptical spherical surface, compressor technology, applied in mechanical equipment, machine/engine, variable displacement pump components, etc., can solve the problems of complex valve movement laws, low work efficiency, and high intake valve failure rate, and improve the design. Mach number, improved efficiency of the whole machine, and small geometric flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

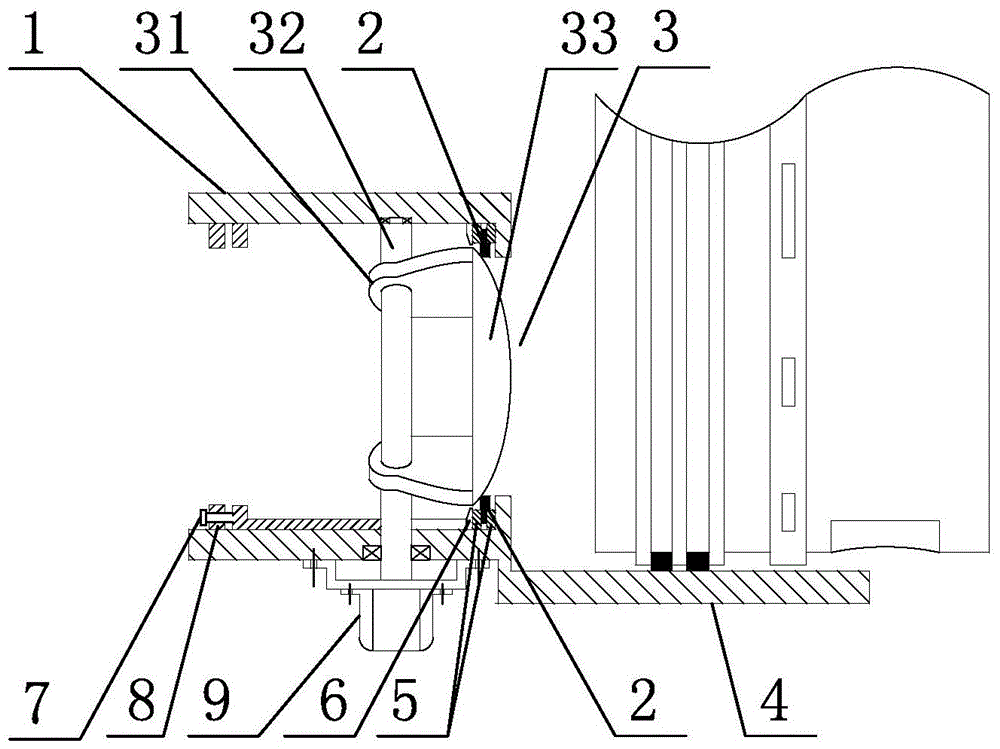

[0019] Such as figure 1 As shown, the reciprocating compressor 4 elliptical spherical plug-type intake valve of the present embodiment includes a cylindrical valve body 1, a valve seat 2 and a valve core 3 located in the valve body 1, and the valve body 1 can be welded or flanged directly. Connect to the intake port of compressor 4 cylinder.

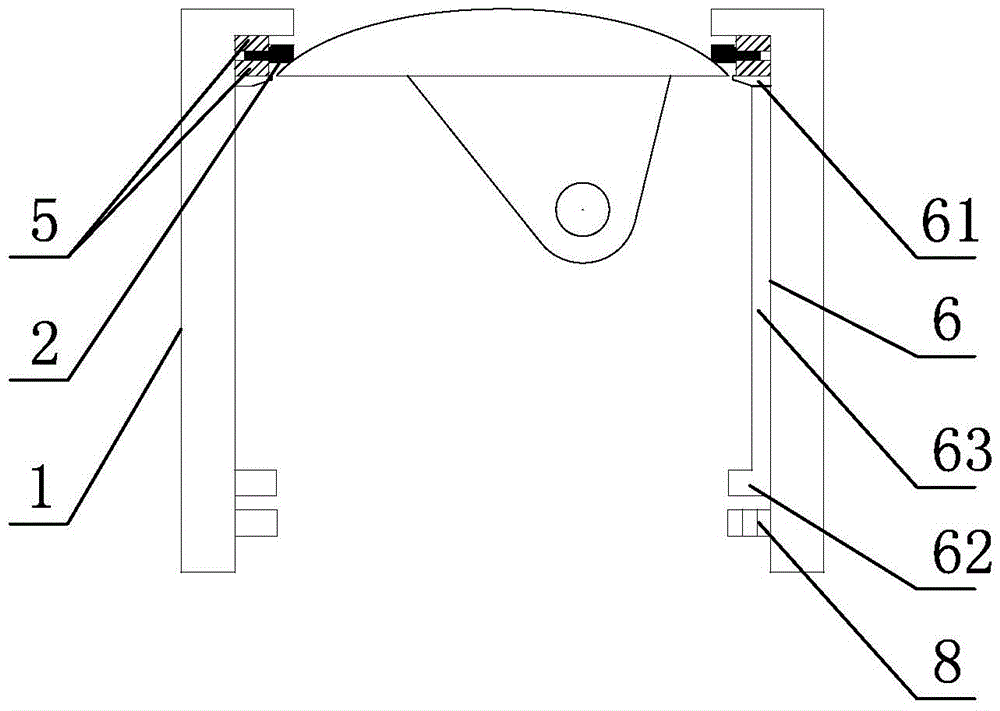

[0020] Such as figure 2 As shown, the valve seat 2 is an annular valve seat 2. The annular valve seat 2 can be made of wear-resistant non-metallic materials such as PEEK, and is installed at the air outlet of the valve body 1. Elastic seals are provided on both sides of the annular valve seat 2. There are two pieces 5, that is, two elastic seals 5, one of which is set on the side of the annular valve seat 2 facing the air outlet of the valve body 1, and the other is set on the side of the annular valve seat 2 facing the air inlet of the valve body 1 The elastic sealing member 5 is preferably an annular elastic sealing washer, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com