Miniature inclined surface vibration reducer

A shock absorber and slope technology, which is applied in the field of micro-slope shock absorbers, can solve problems such as inability to achieve vibration reduction, and achieve the effects of stable and reliable reciprocating motion, large selectivity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

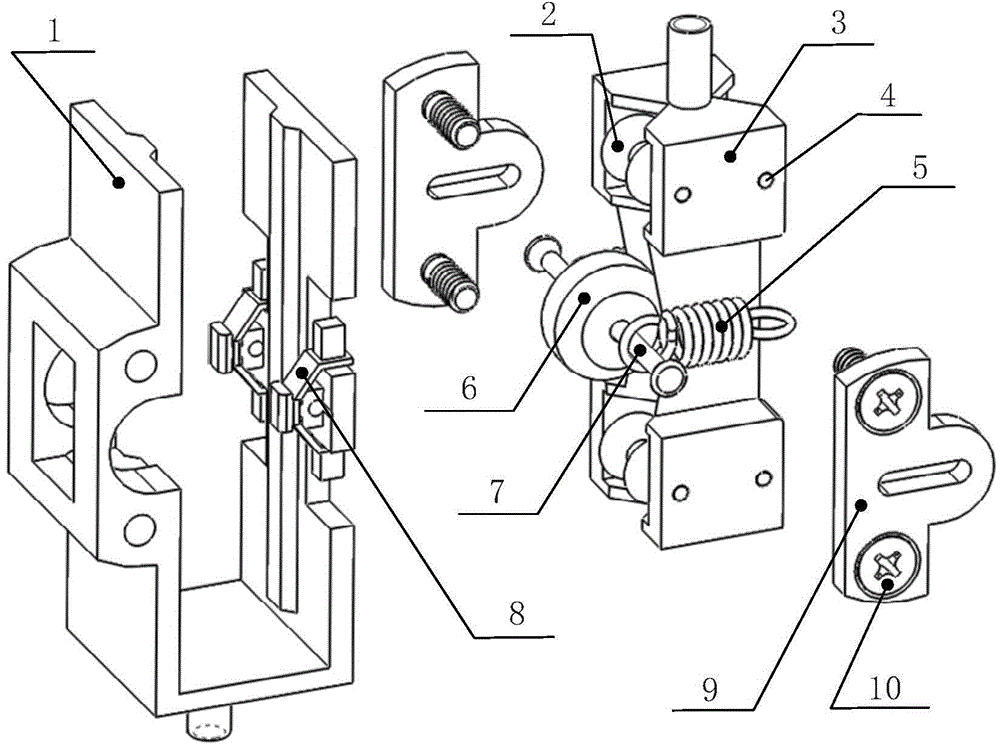

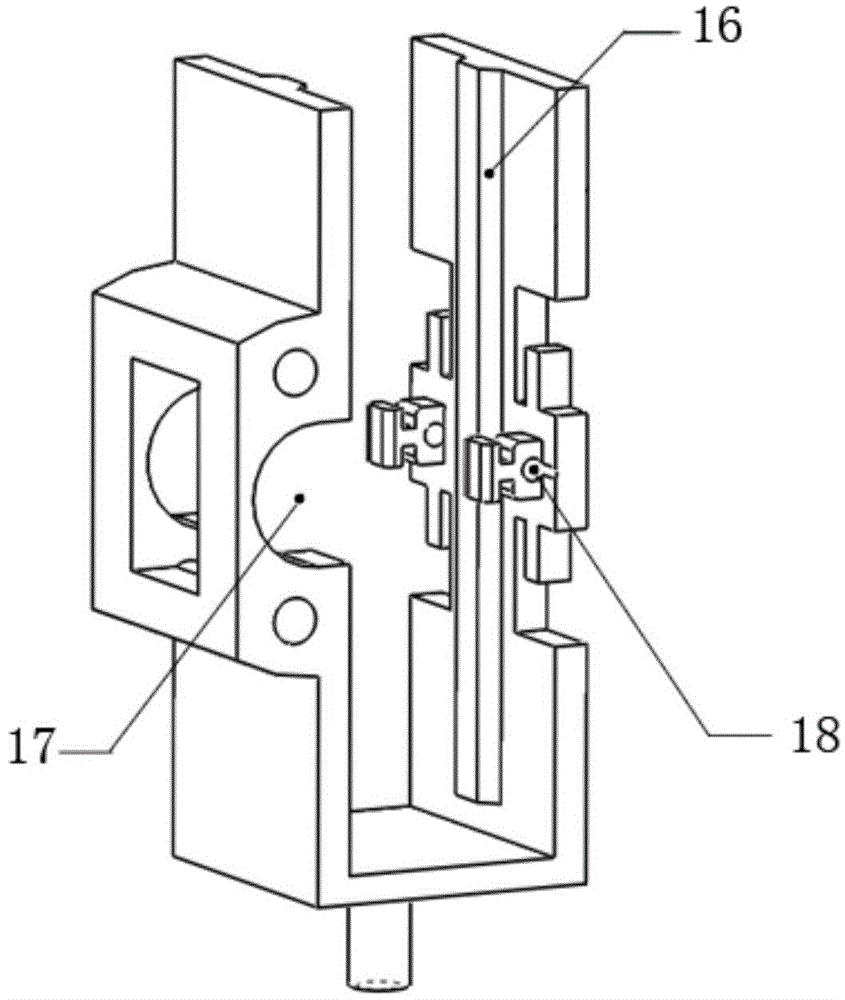

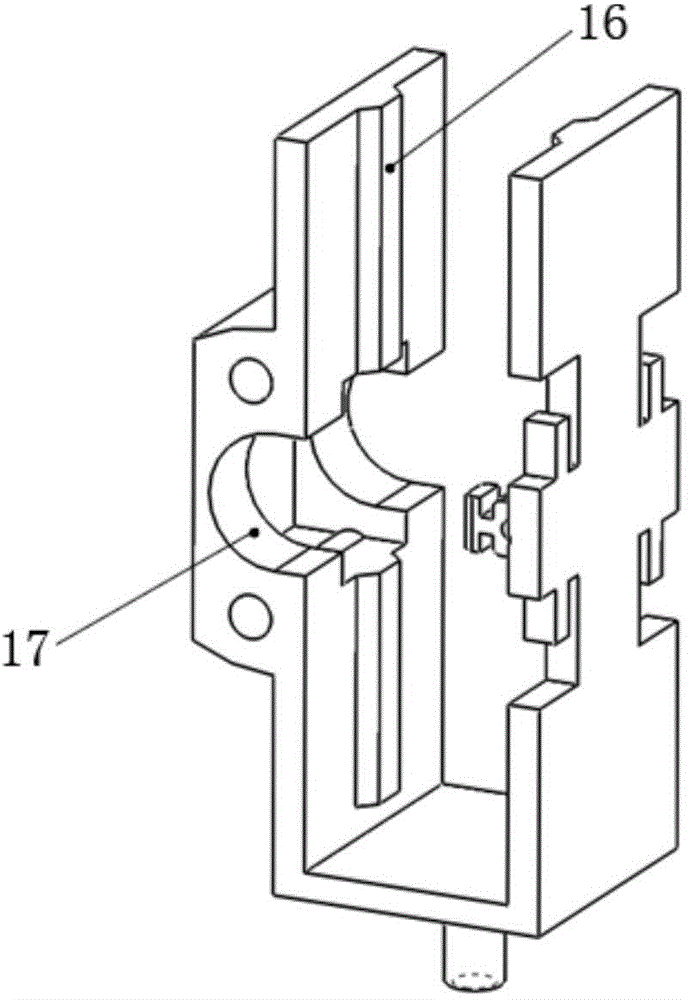

[0025] The parts represented by the symbols in the figure are as follows:

[0026] 1. Outer cylinder; 2. Guide roller; 3. Actuating member; 4. Roller shaft; 5. Extension spring; 6. Roller; 7. Roller shaft; 8. Elastic block; 9. Chute piece; Countersunk head screw; 11, micro-slope shock absorber; 12, damping object; 13, vibration foundation; 14, upper slope; 15, lower slope; 16, longitudinal guide rail; 17, cavity; 18, circular through hole.

[0027] Such as Figure 1-Figure 6 As shown, the four guide rollers 2 are respectively coaxially assembled on the four roller shafts 4 fixedly connected with the actuator 3, and the four gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com