Auxiliary offshore oil-well power device with chromium alloy clamp pistons

A technology of auxiliary power and chromium alloy, which is applied in the direction of electric components, wellbore/well parts, production fluids, etc., can solve the problems of staggering maintenance costs, high power source troubleshooting costs, and affecting oil well production, etc., to achieve good rigidity and resistance deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

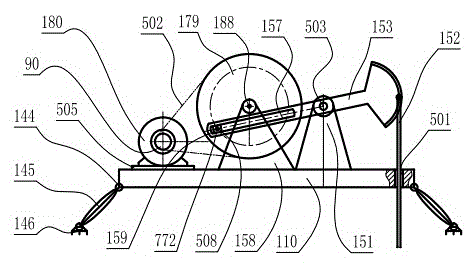

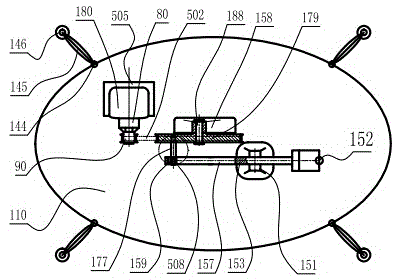

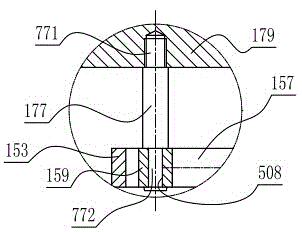

[0042] figure 1 , figure 2 , image 3 and Figure 4 Middle: Auxiliary power facilities for offshore oil wells with chrome alloy clamp pistons. Platform hinges 144 are evenly distributed on the periphery of the working platform 110 to connect with the end of the upper hole of the clamp piston buffer 145, and the end of the lower hole of the clamp piston buffer 145 is connected to the The fixed legs 146 are connected; the motor base 505, the turntable base 158 and the swing base 151 are fixed on the working platform 110, and the drilling swing 153 is rotatably fixed on the swing pin 503 on the swing base 151. The turntable axle pin 188 on the turntable base 158 described above can rotate and fix the synchronous wheel turntable 179, and the described motor base 505 is fixedly equipped with a disc type synchronous wheel motor 180; The big rope 152, the dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com