Sanitary self-operated pressure regulating valve

A pressure-regulating, self-operated technology, applied in the direction of lift valves, valve details, safety valves, etc., can solve the problems of easy breeding of bacteria, easy safety, and inapplicability, so as to achieve the effect of not being easy to safety hazards, hygienic to use, and convenient to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

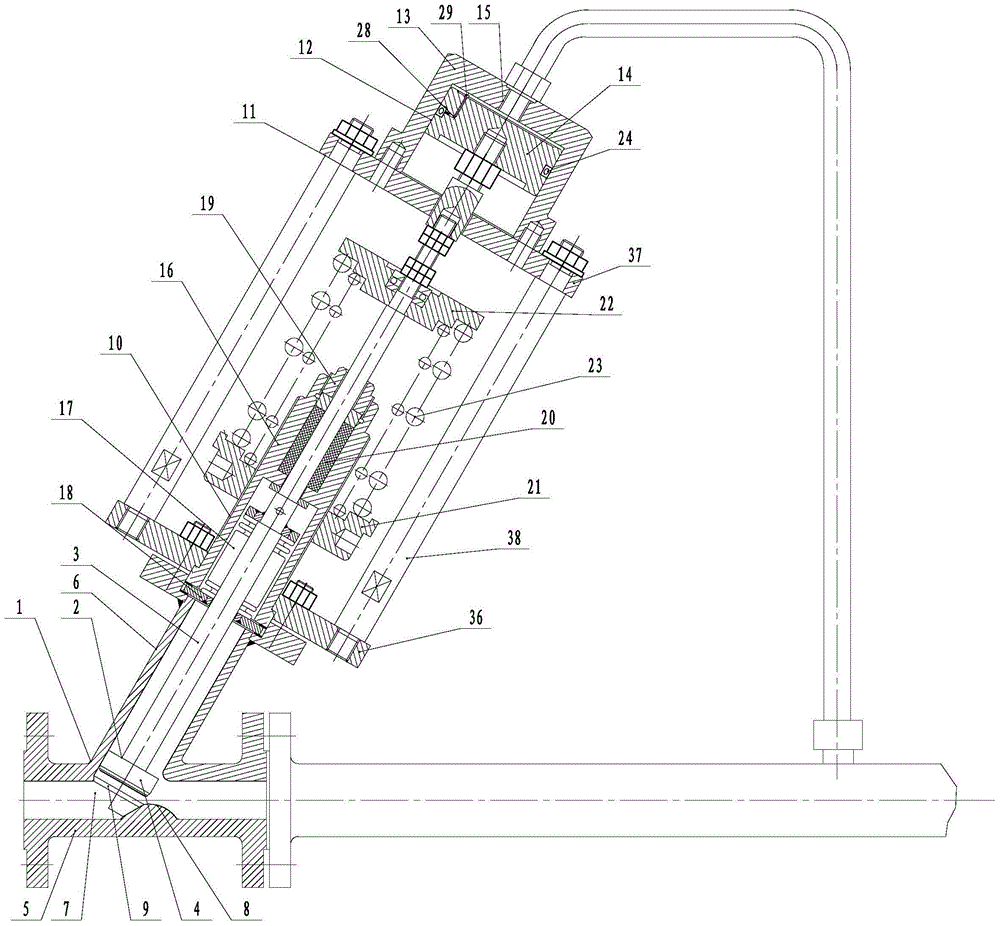

[0024] Embodiment 1: A sanitary self-operated pressure regulating valve (see attached figure 1 ), including a valve body 1, a valve core assembly 2, the valve core assembly includes a valve stem 3, a valve core 4 installed at the lower end of the valve stem, the valve body includes a guide cylinder 5, and an adjustment cylinder 6 communicated with the guide cylinder. The cylinder and the guide cylinder are connected together to form the valve body of the "y" structure and the valve chamber 7 of the "y" structure, and the included angle between the axes of the adjustment cylinder and the guide cylinder is 60 degrees. The valve stem is set in the regulating cylinder, the valve core is set at the connection position between the regulating cylinder and the diversion cylinder, and the inner wall of the diversion cylinder is provided with an arc-shaped protrusion 8 near the position of the valve core, and the arc-shaped protrusion is connected with the inner wall of the diversion cyl...

Embodiment 2

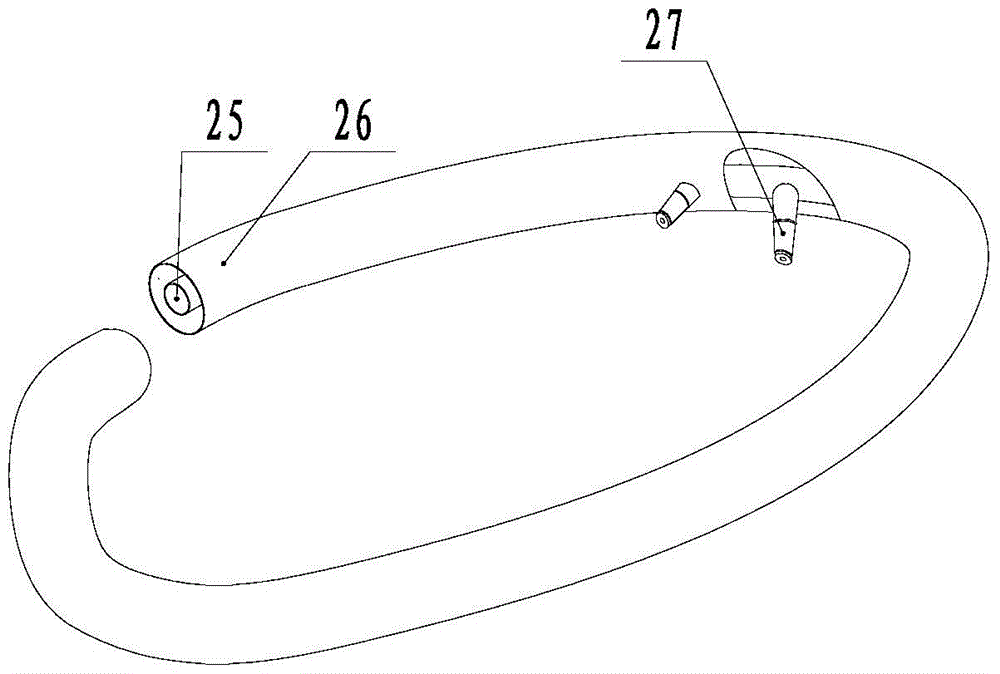

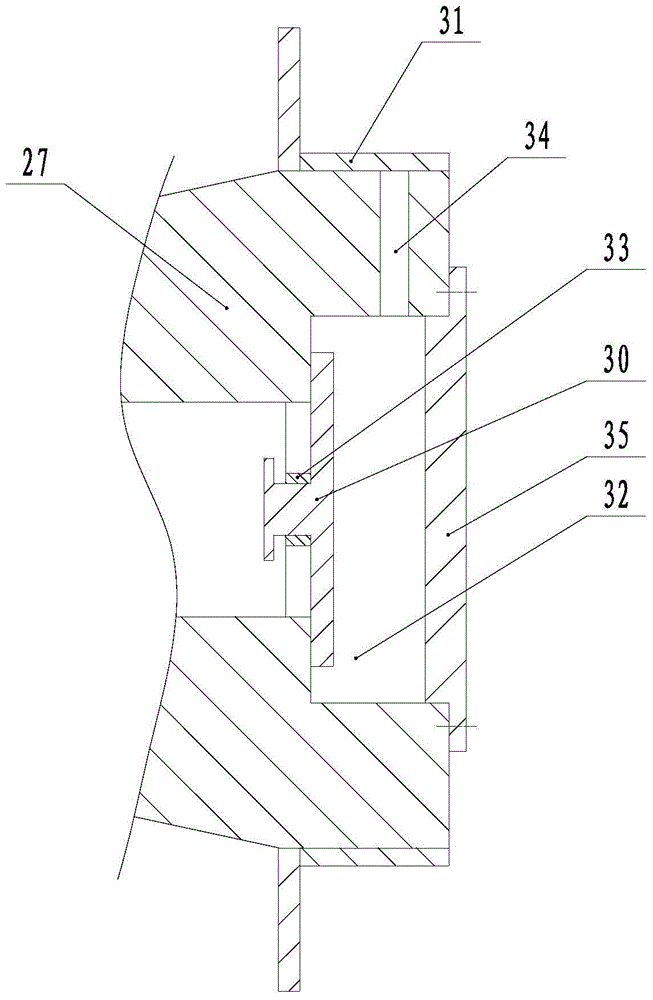

[0026] Embodiment 2: A sanitary self-operated pressure regulating valve (see attached figure 1 , attached figure 2 , attached image 3 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, the outer wall of the push piston is sleeved with a push seal ring 24, the push seal ring includes an inflatable inner ring 25 and an inflatable outer ring 26, and the inflatable inner ring is arranged on the inflatable Inside the outer ring, the cavity between the outer wall of the inflatable inner ring and the inner wall of the inflatable outer ring is provided with colored powder, and an inflatable head 27 is provided on the inflatable inner ring and the inflatable outer ring, and the inflatable head on the inflatable inner ring passes through the inflatable outer ring , the push piston is provided with two inflation connection holes 28 adapted to the inflation head, the inflation connection holes extend to the upper end of the push piston,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com