Expansion joint packing belt

A technology of expansion joints and annular sleeves, applied in the field of expansion joints, can solve the problems of increasing factory costs, accelerating the consumption of spectacle valve spare parts, and the difficulty of reaching the service life of spectacle valves, so as to prolong service life, reduce labor maintenance costs, and reduce maintenance The effect of frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

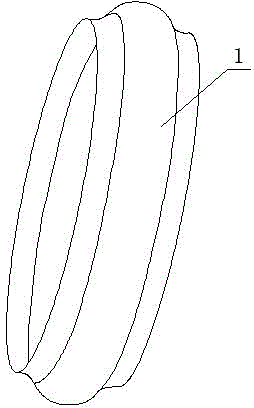

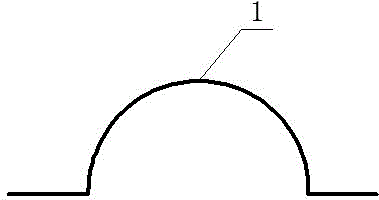

[0015] Figure 1-2 It is a structural schematic diagram of an expansion joint of a glasses valve. The expansion joint includes an expansion joint bead 1, and the expansion joint bead 1 is connected to the pipes on both sides through the horizontal sections on both sides.

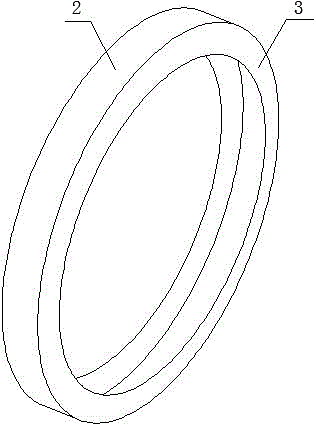

[0016] see Figure 3-4 , an expansion joint packing belt, comprising an annular sleeve 2 and concentric discs 3, two concentric discs 3 are arranged symmetrically on both sides of the annular sleeve 2, and the concentric discs 3 cooperate with the annular sleeve 2 A groove is formed to accommodate the flange 1 of the expansion joint. The diameter of the outer circle of the concentric disc 3 is the same as that of the annular sleeve 2, and the concentric disc 3 and the annular sleeve 2 are connected by full welding to ensure that the weld is seamless. Air holes, trachoma, prefer...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap