Heating device used for steam mop

A steam heating device and steam technology, which are applied in the directions of steam generation, steam generation method, lighting and heating equipment, etc., can solve the problems of poor effect, small coil volume, reduced steam dryness, etc., and achieve high efficiency and good steam quality. , to avoid the effect of channel blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] As mentioned in the background technology, the existing heating devices for steam mops have low heating efficiency, conversion efficiency and heat utilization rate, and the steam outlet effect is not good, easy to block, and the performance of the steam generator is low.

[0037] Next, the specific technical solution of the present invention will be introduced in detail.

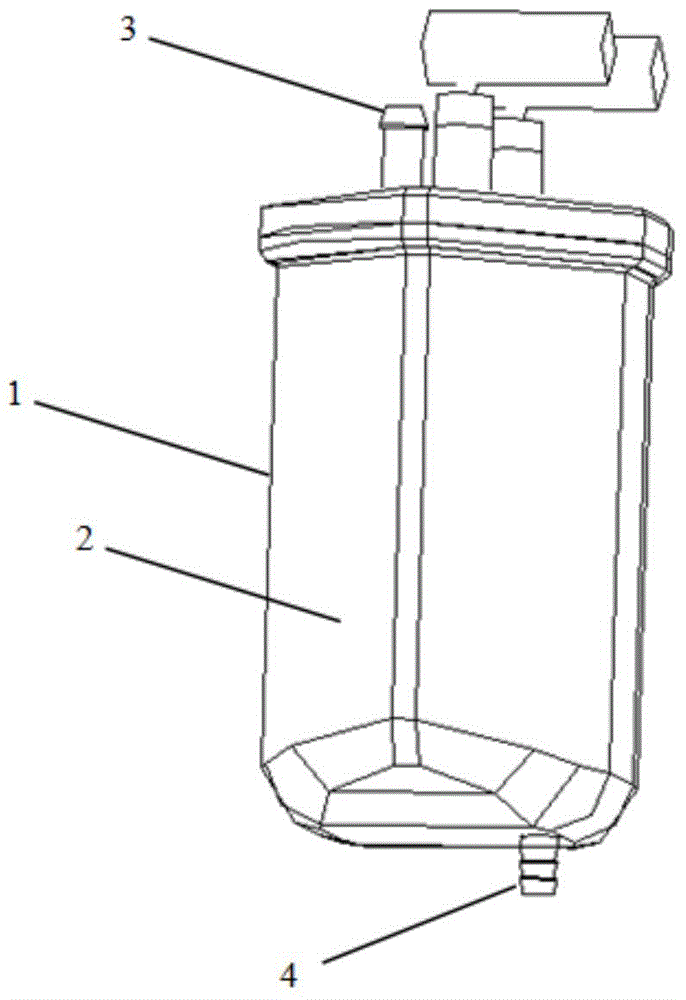

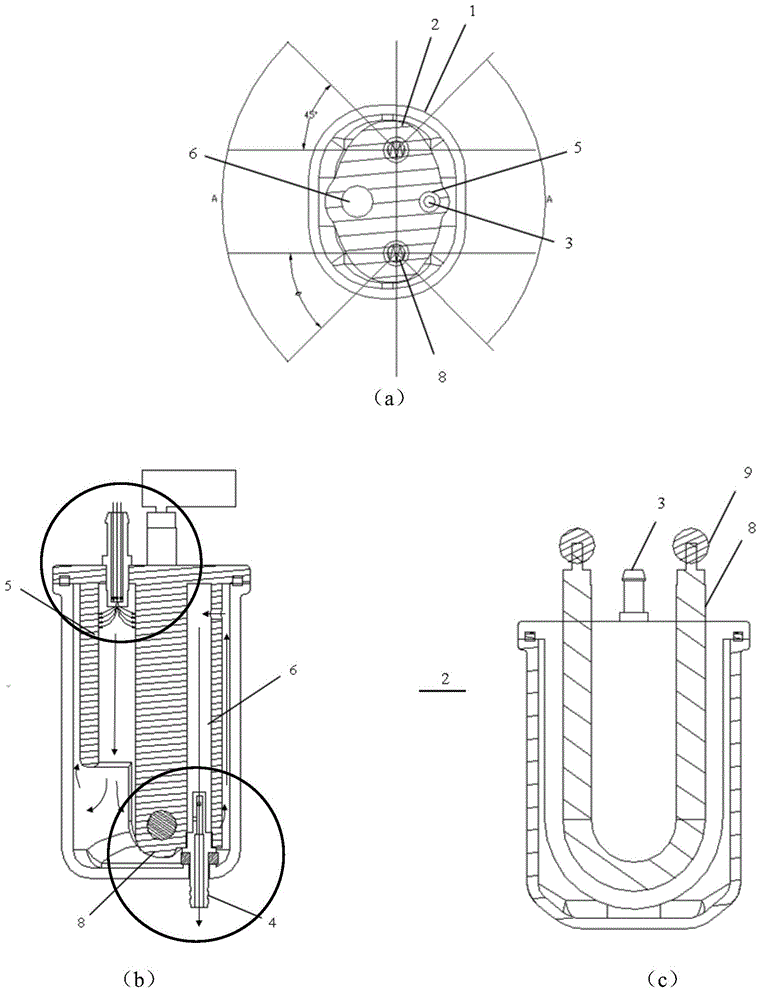

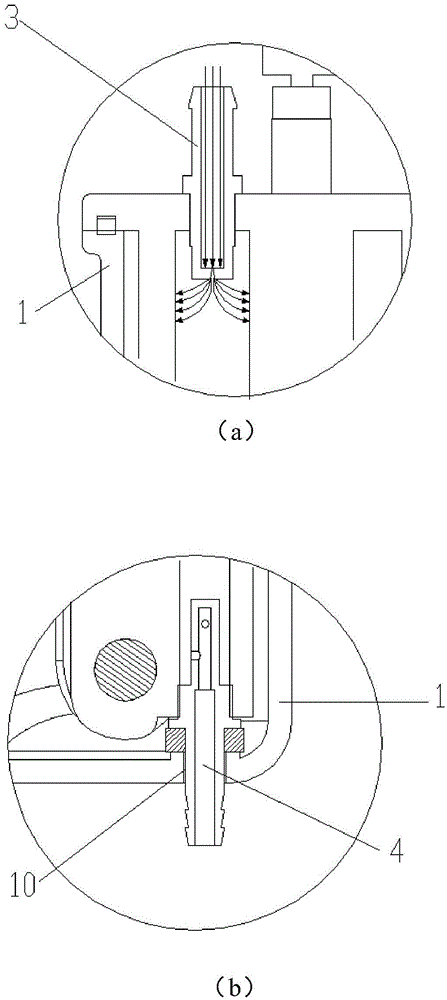

[0038] Please also see figure 1 ~ Figure 7 A heating device for a steam mop in a preferred embodiment of the present invention includes a housing 1, a heating body 2, a water inlet 3 and a steam outlet 4, and the heating body 2 includes a base and extends vertically downward from the base The heating body, the outer diameter of the heating body is smaller than the outer diameter of the base, the heating body is provided with a water inlet channel 5, a steam outlet channel 6 and a heating pipe 8, and the water inlet is arranged on the base The water inlet channel extends vertically along the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com