Method for measuring steel rail appearance geometric dimension and surface quality and device thereof

A technology of surface quality and geometric dimensions, applied in the direction of measuring devices, optical devices, and optical testing of flaws/defects, can solve the problems of reducing the quality of finished rails, increasing straightening cycles, and increasing the workload of grinding, so as to improve utilization efficiency, reduce potential safety hazards, and achieve completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

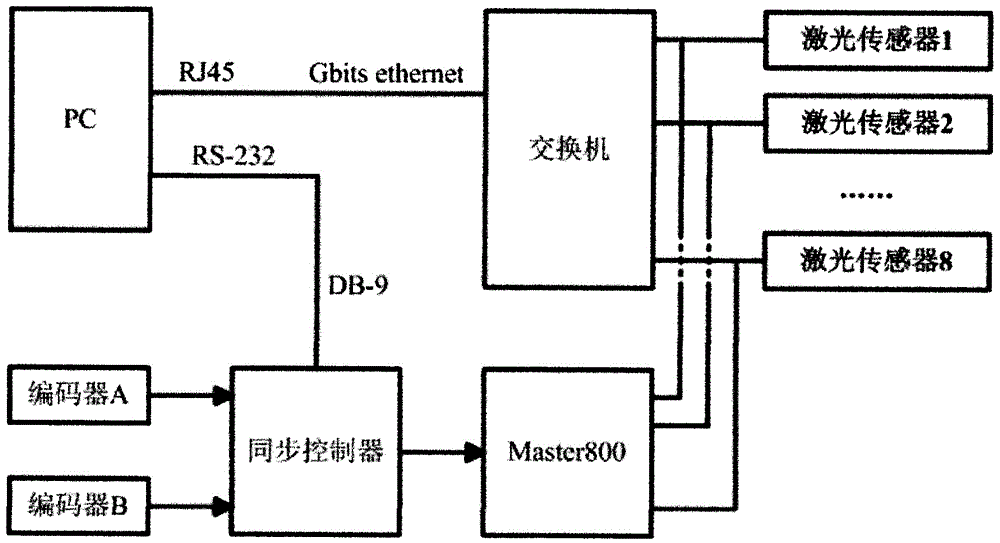

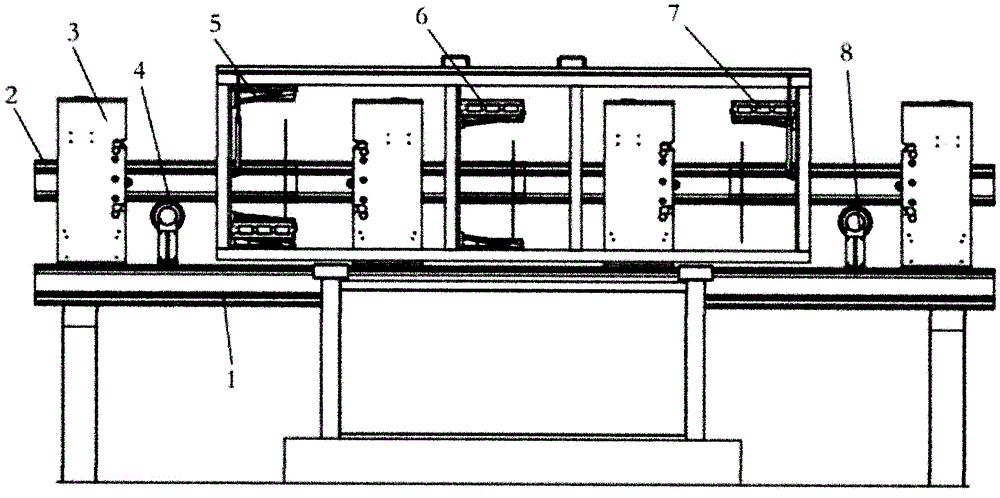

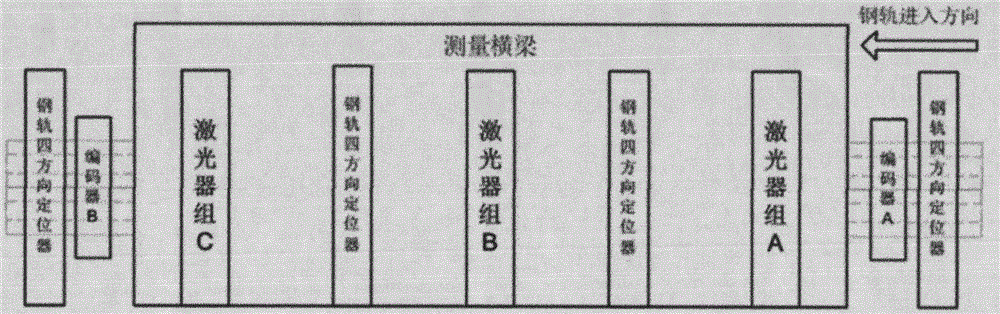

[0038] The method and device for measuring the appearance geometric dimensions and surface quality of rails use laser measurement technology to collect rail cross-section profile data by using three sets of lasers and a total of eight two-dimensional laser sensors in the state of rail movement, and use computer software for data fusion. Stitch each one to obtain the three-dimensional profile of the rail. Automatically analyze the profile of each section of the rail, detect the geometric dimensions of the rail appearance, including rail height, rail top width, rail waist width, rail bottom width, rail top straightness, rail side straightness and rail bottom twist, and detect the surface quality of the rail , such as scratches, scratches, etc., upload the test results to the welding rail production management system, realize automatic rail matching and rail information entry, real-time display of test results, record three-dimensional contour pictures of surface quality defects, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com