Cylinder forced centering observation pillar and embedment method thereof

A technology of forced centering and observation of piers, which is applied in the directions of measuring devices, surveying instruments, surveying and navigation, etc., can solve the problems of poor quality of standard-making construction, difficulty in accurate centering, and poor aiming eccentricity, so as to save pier bodies Concrete material, reduce the centering error, and eliminate the effect of aiming eccentricity difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

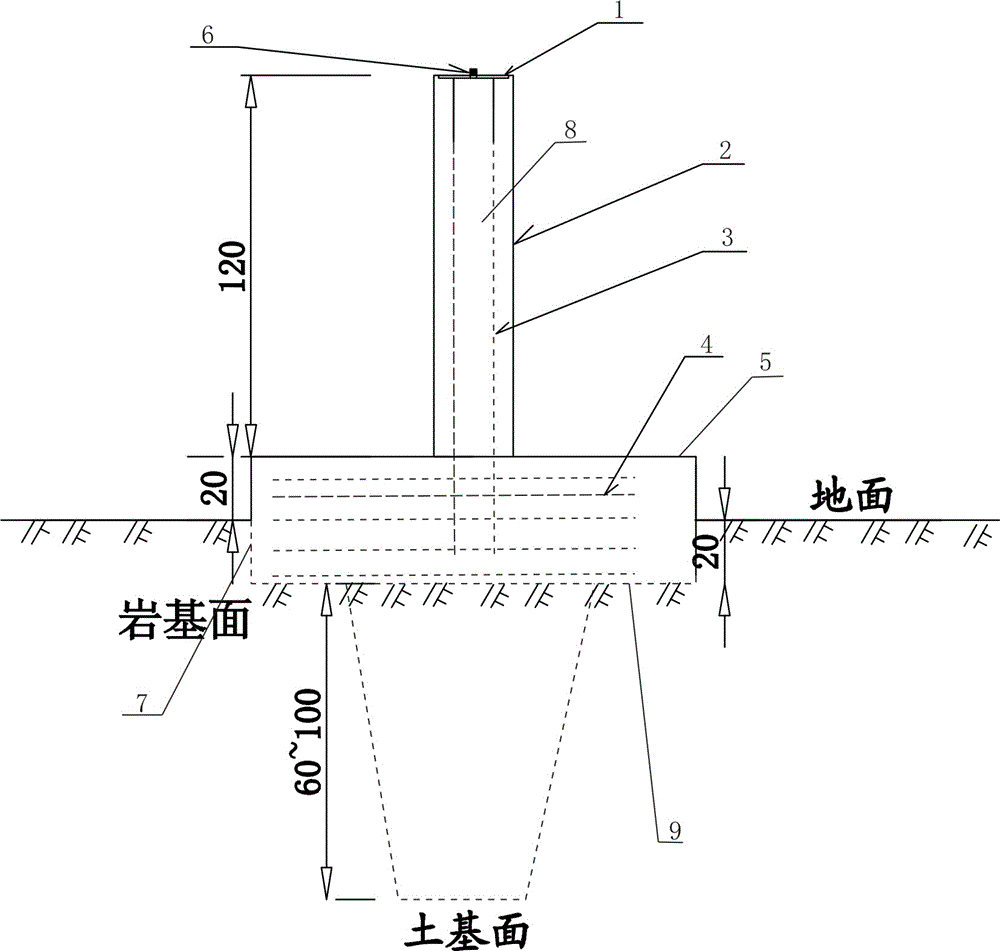

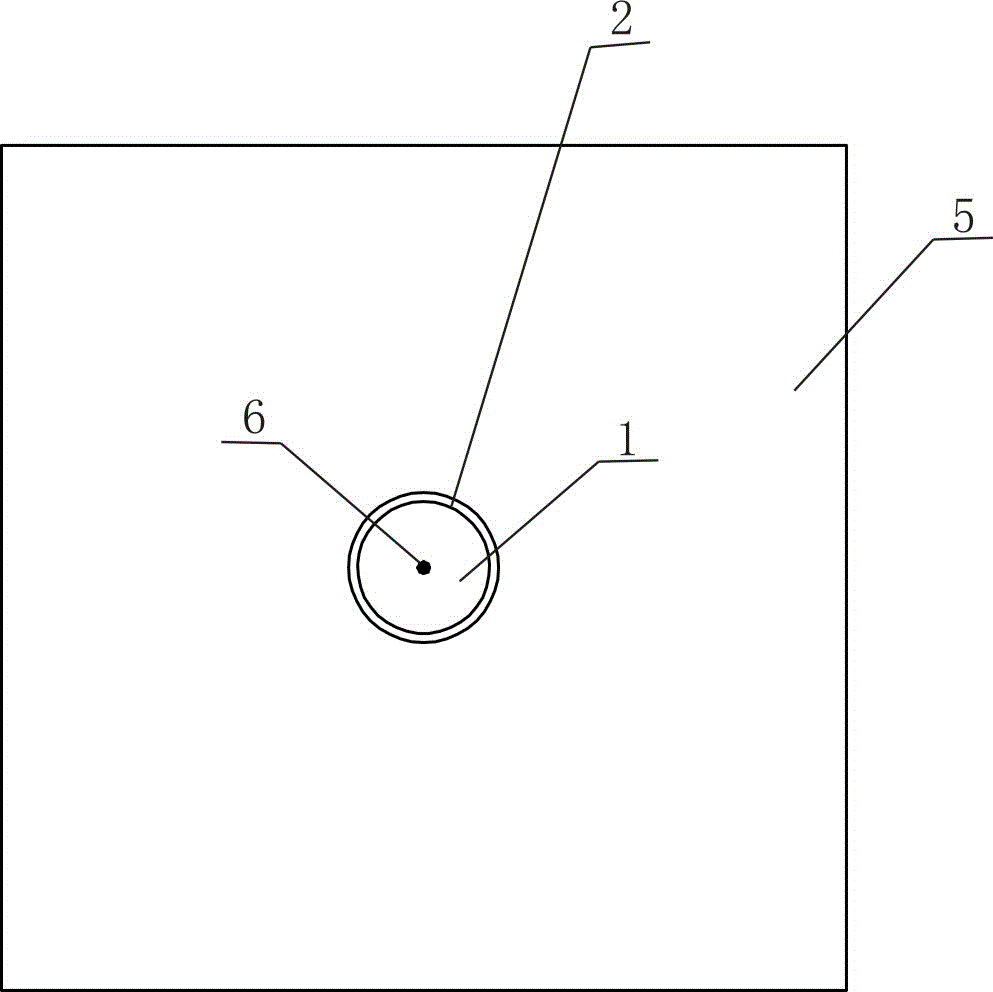

[0031] Such as figure 2 and image 3 As shown, a cylindrical forced centering observation pier,

[0032] It includes a cylindrical pipe body 2 as a pouring template, the lower part of the cylindrical pipe body 2 is wrapped with a concrete chassis 5 integrated with the cylindrical pipe body 2, and the lower part of the concrete chassis 5 is buried in the pile hole 7 under the ground surface Inside;

[0033] The height of the concrete chassis 5 above the ground is 20cm, and the height buried in the ground is 20cm;

[0034] The upper part of the cylindrical pipe body 2 is located on the concrete chassis 5 on the ground surface, and the upper concrete column 8 integrated with the cylindrical pipe body 2 is poured in the cylindrical pipe body 2, and the upper concrete column 8 is connected with the concrete chassis 5. as one;

[0035] The center of the top surface of the upper coagulation column 8 in the cylindrical pipe body 2 is fixedly provided with a forced centering dial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com