Low permeability rock gas permeation test device and method under air and heat coupling effect

A technology of thermomechanical coupling and gas permeation, which is applied in the directions of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems such as unconsidered, mechanical property degradation, uncontrollable temperature, etc., to ensure sealing, The effect of high degree of automation and avoiding experimental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

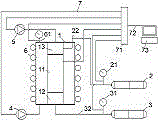

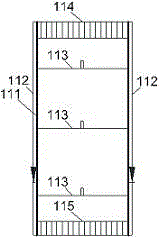

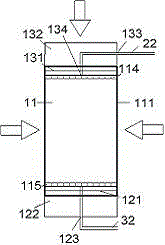

[0022] Such as figure 1 As shown, the low-permeability rock gas permeability test device under the action of gas-thermal-mechanical coupling includes: triaxial pressure chamber 1, high-pressure tank 2, low-pressure tank 3, confining pressure loader 4, axial pressure loader 5, and temperature heater 6 and data transmission acquisition processor 7; wherein: high pressure tank 2, low pressure tank 3 and confining pressure loader 4, axial pressure loader 5 are connected with triaxial pressure chamber 1 respectively, realize gas pressure application and different stress modes, different Loading of the stress path; the temperature heater 6 is close to the triaxial pressure chamber 1 and seamlessly surrounds the triaxial pressure chamber 1 to realize the control of the test temperature; the data transmission and acquisition processor 7 is respectively connected to the triaxial pressure chamber 1 and the high pressure tank 2. The low-pressure tank 3, the confining pressure loader 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com