A kind of aluminum-clad steel wire and its manufacturing process

An aluminum-clad steel wire, manufacturing process technology, applied in the direction of cable/conductor manufacturing, root rod/rod/wire/strip conductor, power cable, etc., can solve problems such as large power consumption, easy cracking of aluminum layer, environmental pollution, etc. , to achieve the effects of environmental protection in the manufacturing process, stable quality assurance, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The manufacturing method of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

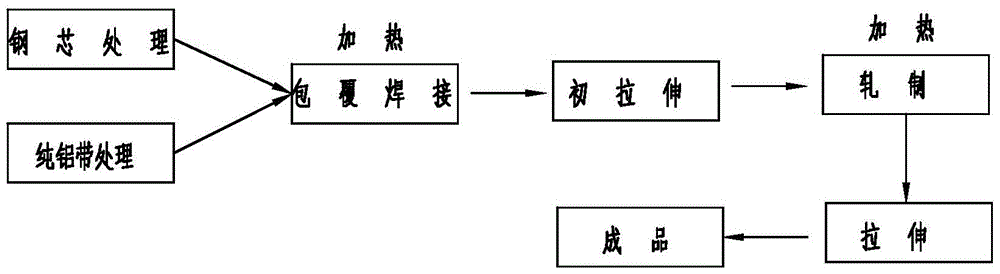

[0031] figure 1 It is a flowchart of the aluminum-clad steel wire manufacturing process of the present invention, and the process comprises the following steps:

[0032] (1) According to the specifications of the pre-processed aluminum-clad steel wire products, select steel wires with a wire diameter of 4.5-16mm. The steel wires are common medium and low carbon steels, and the steel raw materials are made of high-quality carbon with a carbon mass fraction of 0.1% to 0.7%. For steel wire rod, it is necessary to remove the oxide layer on the surface of the steel wire rod at 360° before coating, and then use a No. 70 steel wire brush to brush and grind for 2-3 times to achieve no scale and other media, and then pull it out The wire diameter required for coating is 4.3-12mm;

[0033] (2) Tempering the steel wire disc with brush...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com