Pre-charging device and method of electric automobile

An electric vehicle and pre-charging technology, applied in electric vehicles, battery circuit devices, circuit devices, etc., can solve the problems of inability to meet the requirements of high-voltage power-on time, affecting charging speed, and small charging current, so as to improve user experience and improve user experience. Vehicle performance, the effect of shortening the high-voltage pre-charge time, and shortening the high-voltage power-on time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

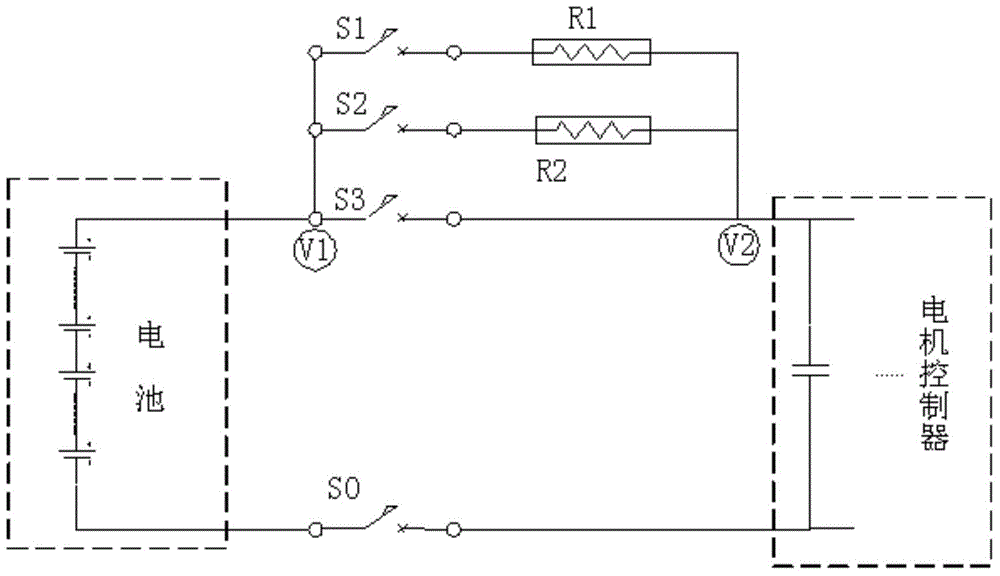

[0039] A kind of electric vehicle precharging device is provided in this embodiment, such as figure 1 As shown, it includes a battery system and a load circuit. The negative output terminal of the battery system is connected to the negative terminal of the load circuit through a controllable switch S0, and the positive output terminal of the battery system is connected to the positive terminal of the load circuit. terminals are connected through the S3 switch, and there is also a multi-stage pre-charging circuit connection between the positive output terminal of the battery system and the positive terminal of the load circuit, and the multi-stage pre-charging circuit can provide variable resistance as required Resistance value, the multistage precharge circuit in the present embodiment comprises:

[0040] Two pre-charging circuits are arranged in parallel between the positive output end of the battery system and the positive connection end of the load circuit, and each pre-cha...

Embodiment 2

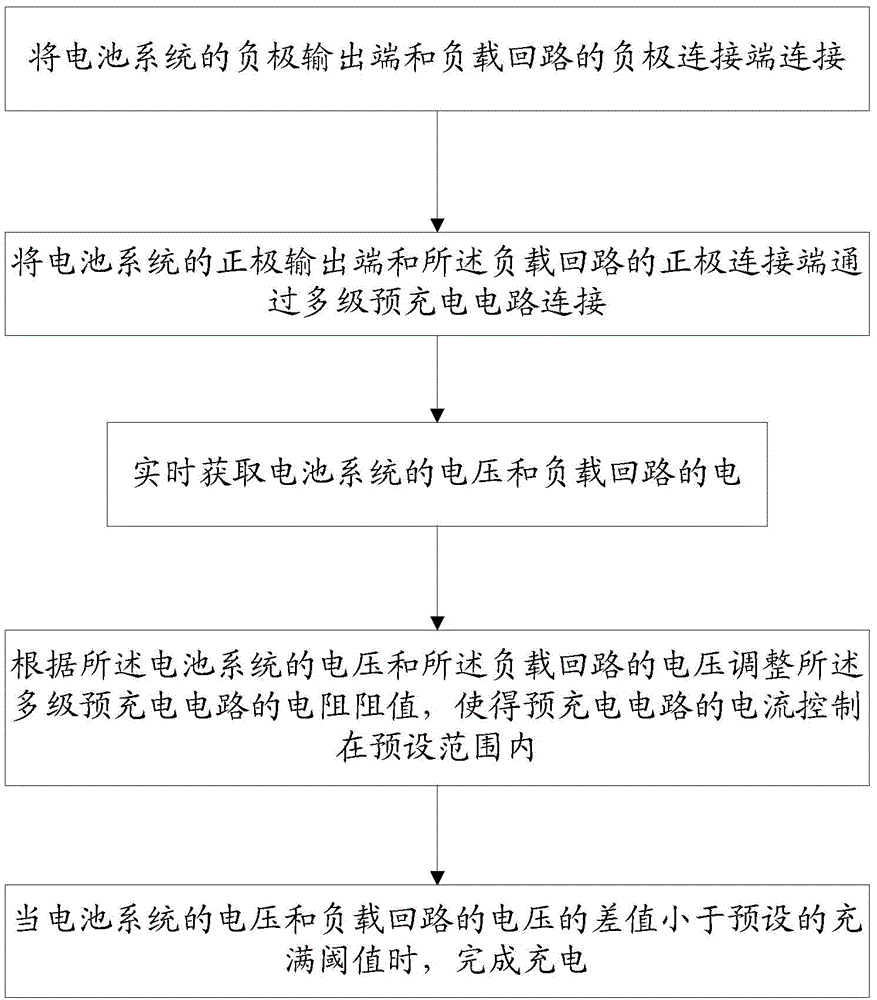

[0044] In this embodiment, a pre-charging control method for an electric vehicle is provided, which is used for figure 1 In the pre-charging device of , comprise the following steps:

[0045] First, after receiving the high-voltage power-on command, the battery management system closes the negative contactor S0, and connects the negative output terminal of the battery system to the negative terminal of the load circuit.

[0046] Then, obtain the voltage of the battery system and the voltage of the load circuit in real time;

[0047] Next, according to the voltage of the battery system and the voltage of the load circuit, the current state of the system is determined, and a pre-charging mode for starting pre-charging is selected. According to the selected pre-charging mode, the corresponding pre-charging circuit is connected, the equivalent resistance value in the pre-charging circuit is changed, and the voltage increase of the load circuit is controlled.

[0048] During the ...

Embodiment approach

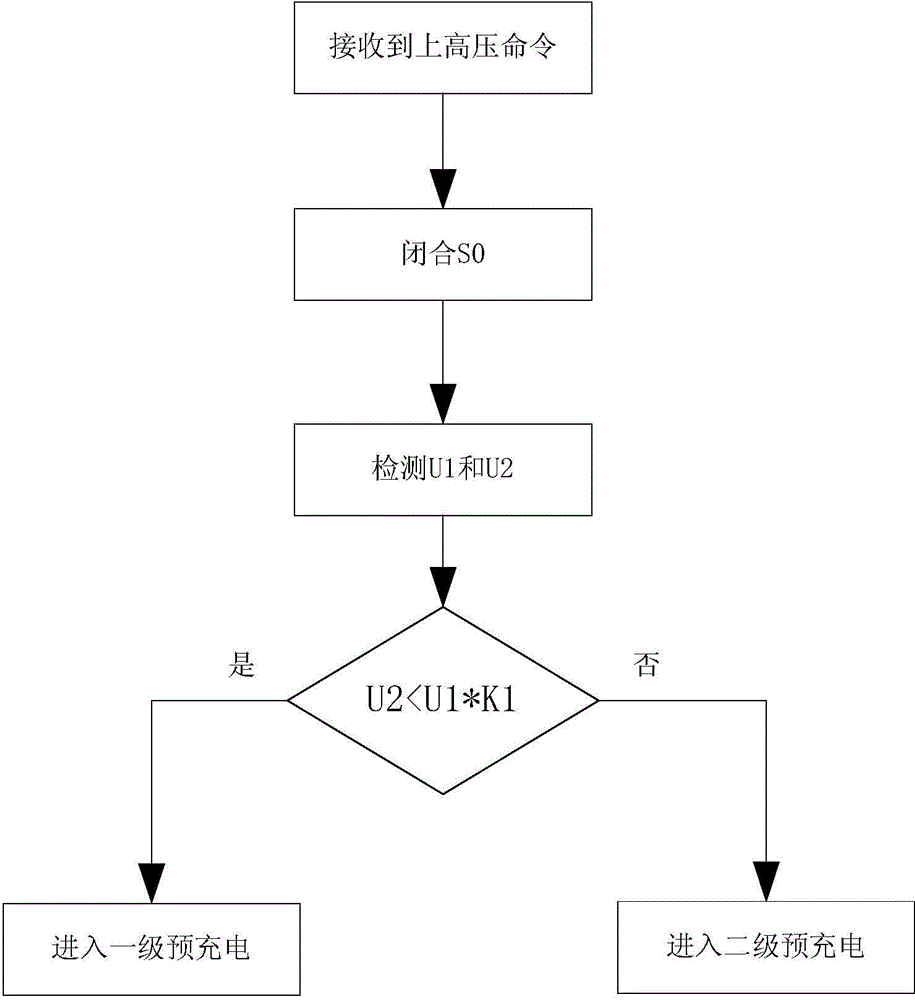

[0055] As a specific implementation, the process is as follows:

[0056] The specific steps are as follows:

[0057] First, detect battery-side voltage U1 and load-side voltage U2, and compare U1 and U2. If U2U1*K1, enter the second-level pre-charging mode, where K1 is the calibration coefficient. Such as image 3 shown.

[0058] When starting to charge U2<U1*K1, when entering the first-level pre-charging mode, close S1. At this time, S1 is closed, S2 is opened, and the high-voltage circuit is pre-charged through the pre-charging resistor R1.

[0059] The U2 voltage is monitored as the precharge progresses. When U2>U1*K2, enter the three-level pre-charging mode and close S2. At this time, S1 is closed, S2 is closed, and the high-voltage circuit is pre-charged through the pre-charging resistance connected in parallel between R1 and R2, such as Figure 4 shown. This can increase the pre-charging current and quickly increase the voltage across the capacitor.

[0060] If ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com