A Permanent Magnet Assisted Synchronous Reluctance Motor Rotor for High Speed Applications

An auxiliary synchronous and reluctance motor technology, applied in synchronous machine parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc. Suitable for mass production and other issues, to achieve the effect of high cost performance and easy procurement management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

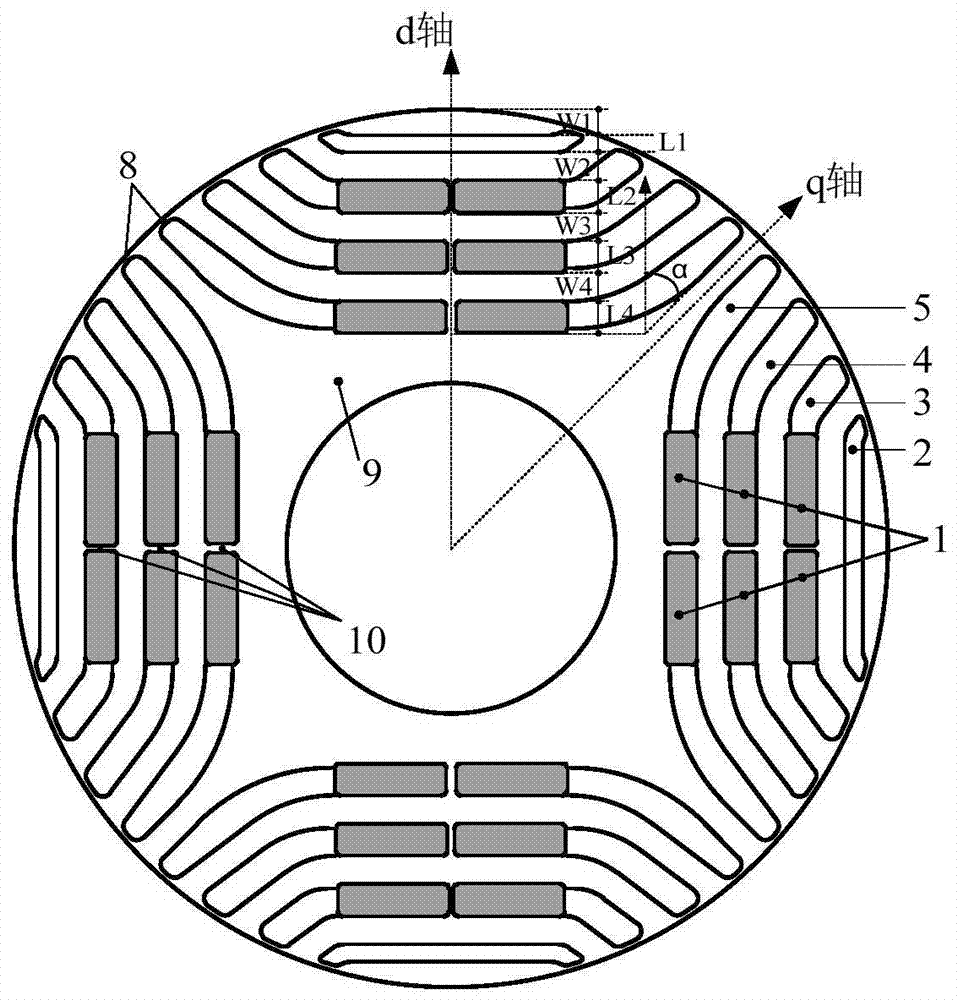

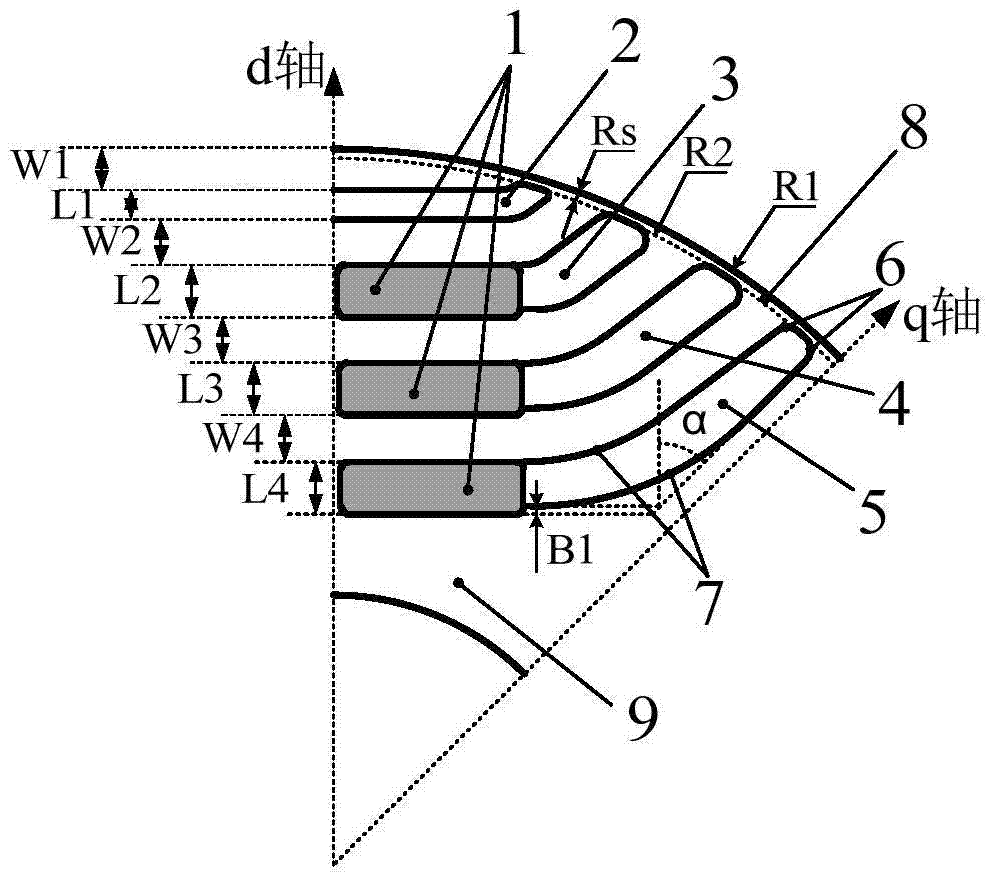

[0033] Refer to attached figure 1 , which is a structural schematic diagram of the permanent magnet assisted synchronous reluctance motor rotor that can be used in high-speed applications provided by the present invention. It can be seen from the figure that the permanent magnet assisted synchronous reluctance motor rotor mainly includes three parts: the rotor yoke (ie, the rotor core), the magnetic barrier disposed on it, and the magnetic steel disposed in the magnetic barrier.

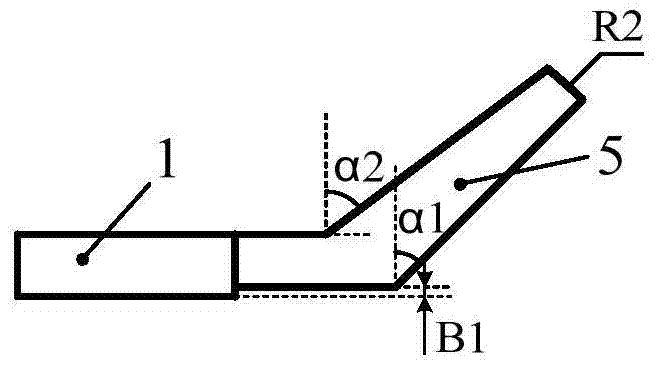

[0034] Among them, the motor rotor scheme distributes four layers of boat-shaped magnetic barriers under each pole of the rotor core 9, and the scheme shown in the figure arranges four layers of boat-shaped magnetic barriers symmetrically in the four pole directions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com