Transverse flux high-speed superconducting motor system

A superconducting motor and transverse magnetic flux technology, applied in the usage of superconducting elements, electrical components, electromechanical devices, etc., can solve the problems that limit the application and development of superconducting motors, and achieve the effect of improving current carrying capacity and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

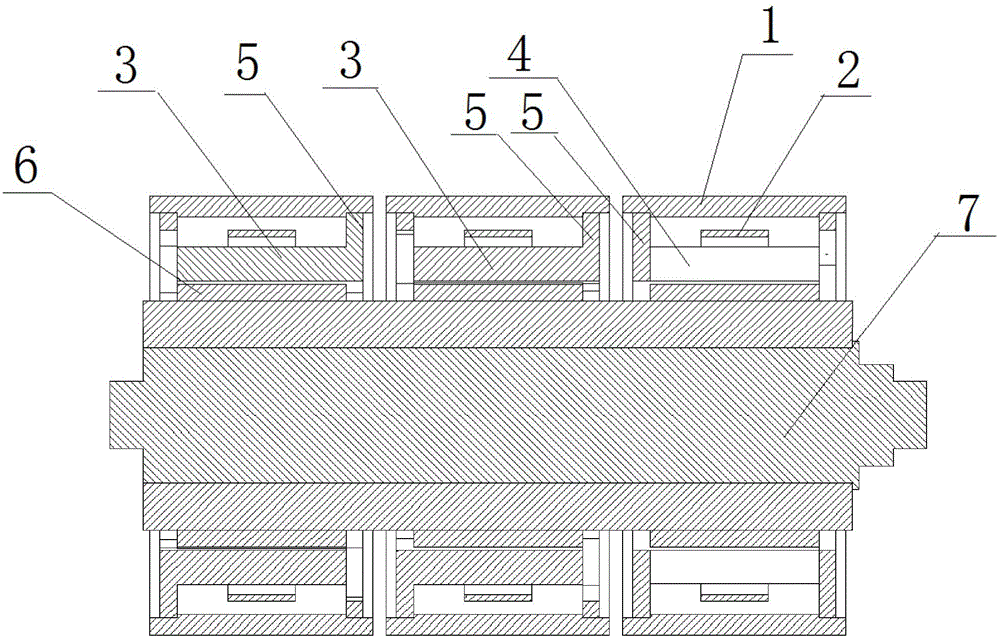

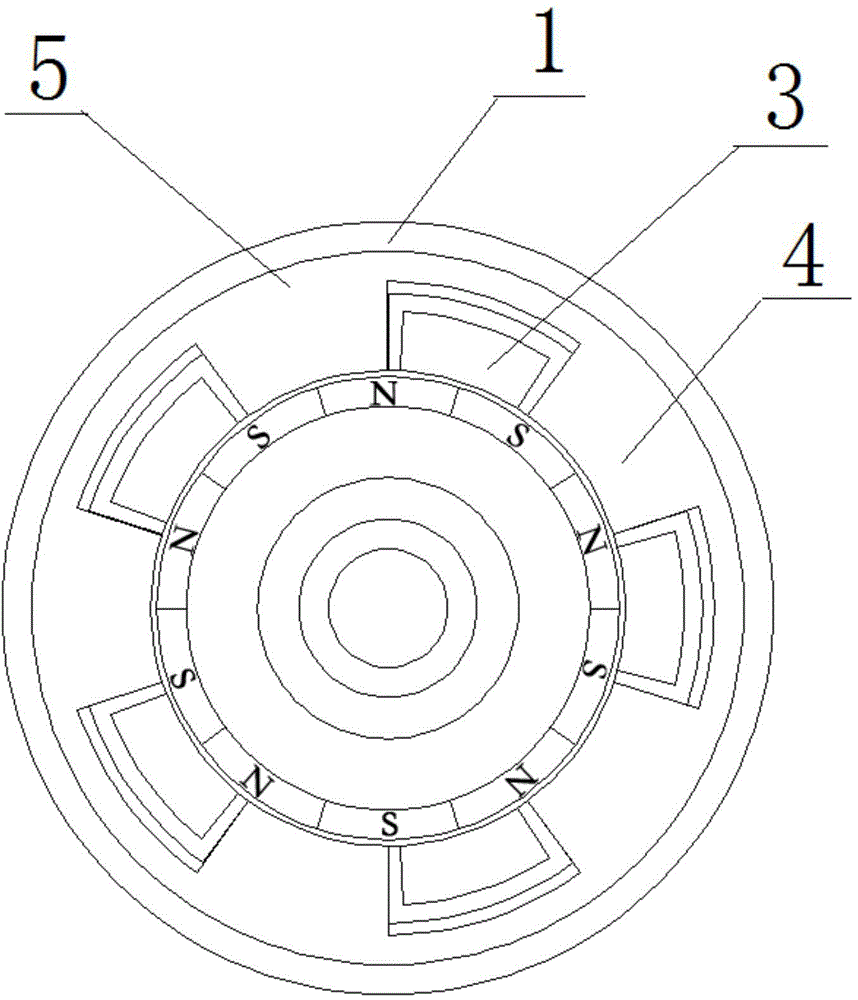

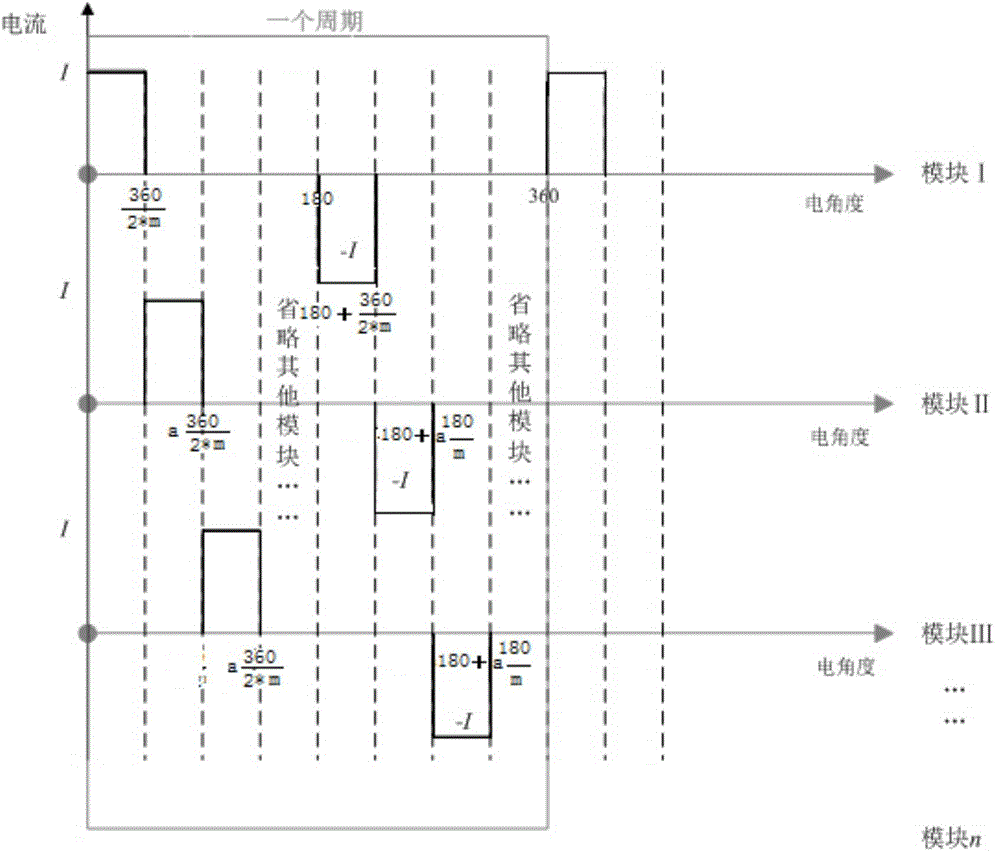

[0026] Such as figure 1 , figure 2 , Figure 5 and Figure 6 As shown, a transverse flux high-speed superconducting motor system, the motor is composed of m identical motor modules, where m is greater than or equal to 3; the motor modules include a stator and a rotor.

[0027] The stator includes a stator shaped magnetic conductor, a stator outer magnetic conductor ring 1 and a superconducting coil 2 .

[0028] There are two groups of stator special-shaped magnetizers, which are respectively the first stator special-shaped magnetizer 3 and the second stator special-shaped magnetizer 4; Square tile-shaped magnetic guide plate, the rectangular tile-shaped magnetic guide plate is connected with the outer ring 5 and forms an equidistant tooth structure (the magnetic guide plates adopted between the motor modules of the present invention are all the same); the first stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com