Polarizing plate, optical film and image display device

A technology of polarizing plate and cellulose ester film, which is applied in the direction of optics, optical elements, polarizing elements, etc., can solve the problem of panel display unevenness, and achieve the effects of small display unevenness, suppression of phase difference change, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

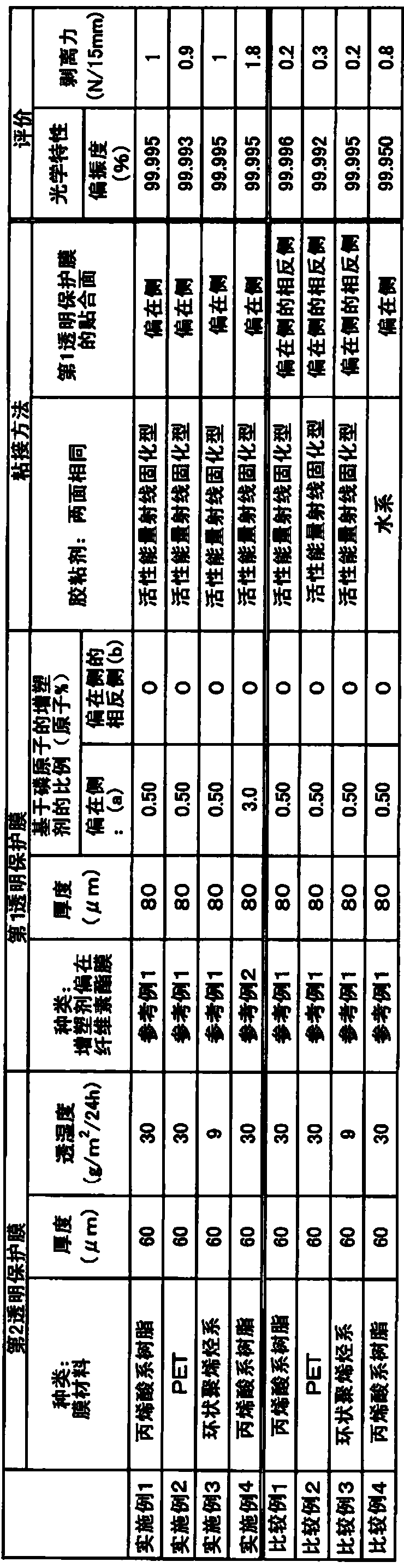

[0110] Hereinafter, examples of the present invention will be described, but the embodiments of the present invention are not limited thereto.

[0111]

[0112] A polyvinyl alcohol film having an average degree of polymerization of 2400 and a degree of saponification of 99.9 mol % and a thickness of 75 μm was immersed in warm water at 30° C. for 60 seconds to swell. Next, the film was dyed while being immersed in an aqueous solution having a concentration of 0.3% of iodine / potassium iodide (weight ratio = 0.5 / 8), and stretched to 3.5 times. Then, stretching was carried out so that the total stretching ratio became 6 times in a borate aqueous solution at 65°C. After stretching, it was dried in a 40° C. oven for 3 minutes to obtain a PVA-based polarizing plate (thickness: 23 μm).

[0113]

reference example 1

[0115] A plasticizer-localized cellulose ester film with a thickness of 80 μm was obtained. The ratio (a) of the phosphorus-based plasticizer based on phosphorus atoms on the side of the film is 0.5 atomic %; the ratio (b) of the phosphorus-based plasticizer on the opposite side of the film is 0 atom%.

[0116] The cellulose ester film in which the above-mentioned plasticizer is partial is produced by the following method.

[0117] 100 parts by weight of cellulose triacetate (the degree of acetyl substitution is 2.88, and the number average molecular weight is 150,000),

[0118] 10 parts by weight of triphenyl phosphate (phosphorus plasticizer),

[0119] 2 parts by weight of ethyl phthalate ethyl glycolate

[0120] チヌビン 326 (manufactured by Ciba Specialty Chemicals Co., Ltd.) 1 part by weight

[0121] AEROSIL 200V (manufactured by Aerosil Japan) 0.1 parts by weight

[0122] Acicular TiO 2 (manufactured by Ishihara Sangyo Co., Ltd., trade name FTL-100) 5 parts by weight ...

reference example 2

[0131] A plasticizer-localized cellulose ester film having a thickness of 80 μm was obtained. The ratio (a) of the phosphorus-based plasticizer based on phosphorus atoms on the side of the film is 3 atomic %; the ratio (b) of the phosphorus-based plasticizer on the opposite side of the film is 0 atom%. In the reference example 1, except having changed the compounding ratio of the triphenyl phosphate to 60 weight part, it carried out similarly to the reference example 1, and prepared this film.

[0132] Determination of the proportion of plasticizer

[0133] The proportions (a: atomic %) and (b: atomic %) of the plasticizer in the cellulose ester film were measured based on the phosphorus atoms in the plasticizer by ESCA. It should be noted that the measurement of the above-mentioned ratio (a) is carried out on the range from the side where the plasticizer is biased to a thickness of 5 nm (the biased side), and the measurement of the above-mentioned ratio (b) is from the oppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com