Following rotation preventing rotary blade reverse type mini-tiller

A micro-tiller and reverse-type technology, which is applied in the field of micro-tillers, can solve problems such as failure to achieve results, lower production efficiency, and reduced safety of finished micro-tillers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

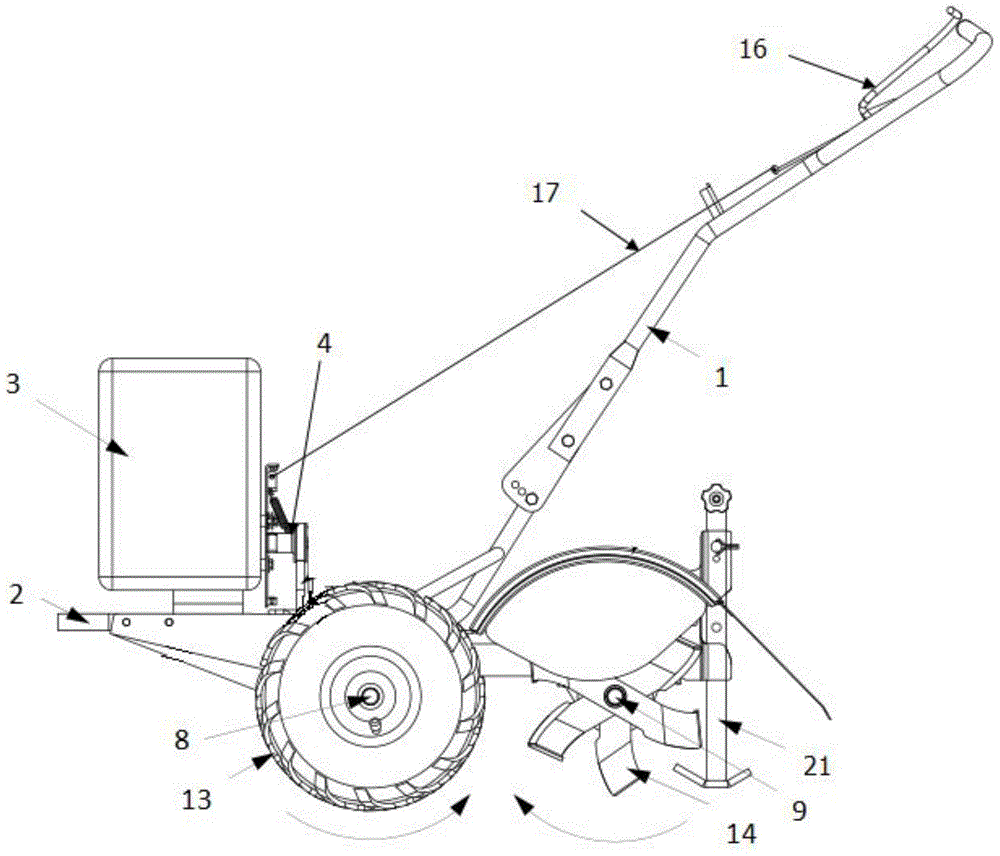

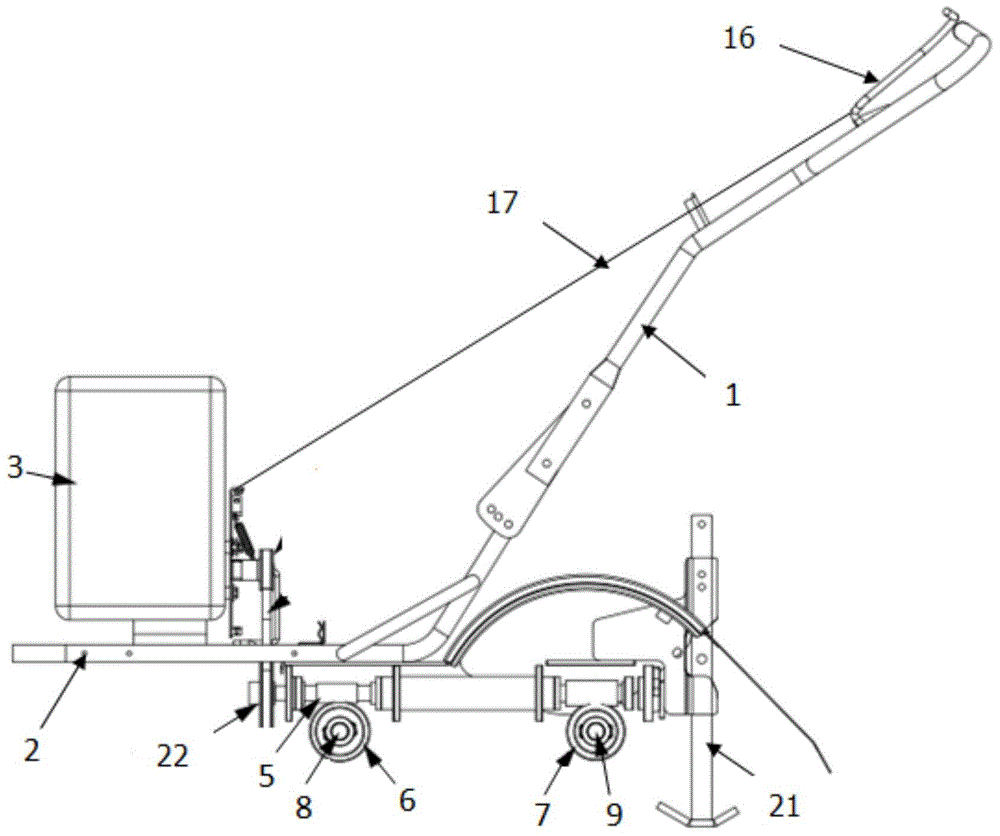

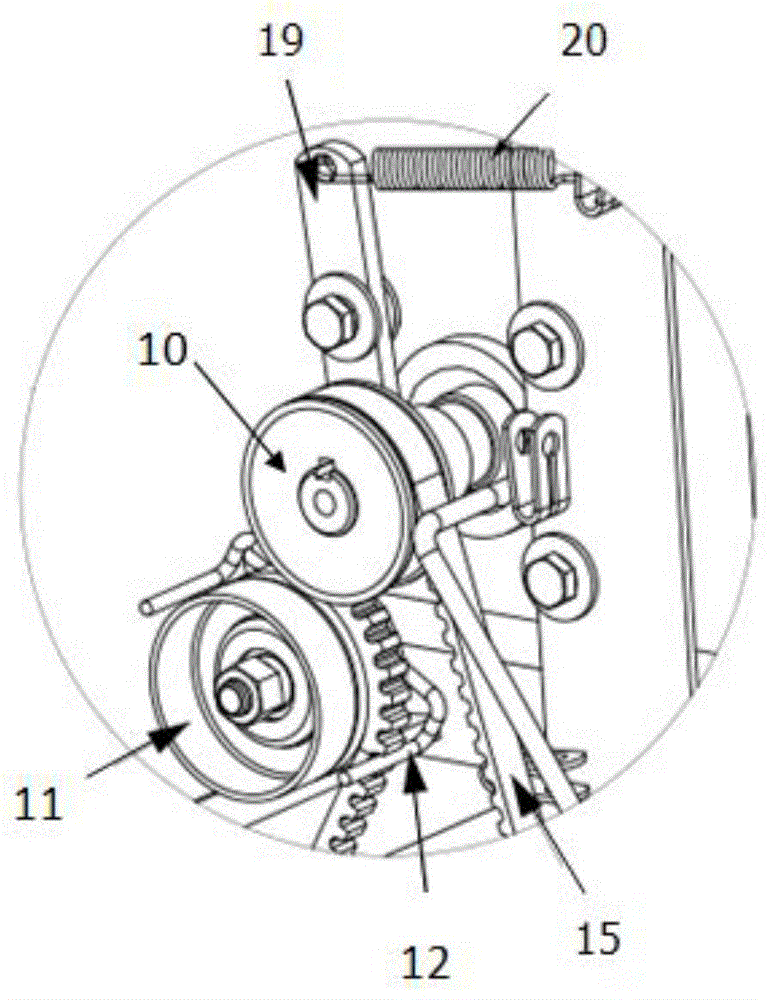

[0022] Such as Figure 1-Figure 4 In the anti-heel-rotating cultivating knife reverse micro tillage machine shown, the handrail 1 is connected to the frame 2, and the power 3 is connected to the frame 2. The power 3 is connected to the wheel 13 and the tiller 14 through the transmission mechanism 4, and is located on the handrail 1. The clutch switch 16 is connected to the transmission mechanism 4 through the connection line 17. The transmission mechanism 4 includes an inner toothed belt 15 which is sleeved and connected between the driving wheel 10 and the tension pulley 18. The inner tooth surface of the inner toothed belt 15 is connected to the The driving wheel 10 fits loosely, the non-internal tooth surface of the belt with internal cogging 15 fits loosely with the tensioning wheel 18, the thickness of the belt 15 with internal cogging is 0.1 cm, the depth of the internal teeth is 0.5 cm, and the belt stopper 12 Connected with the tensioning wheel 18, the distance between...

Embodiment 2

[0024] When utilizing a kind of anti-following tiller described in embodiment 1 to work, start the power 3, and when pressing the clutch switch 16, the connecting wire 17 will lift the tension arm 19, causing the tension spring 20 Tensile deformation is generated, and the tension arm 19 drives the tension wheel 18 to press the inner cogged belt 15, so that the inner cogged belt 15 and the driving wheel 10 are closely attached, and at the same time, the belt stopper 12 and the inner cogged belt The internal cogging of 15 is separated. At this time, the friction between the internal cogged belt 15 and the driving wheel 10 drives the driving wheel 10 to rotate, and the driving wheel 10 drives the driven wheel 22 to rotate through the internal cogging belt 15, thereby driving the worm 5 rotates, and now the wheel worm gear 6 and the cultivating blade worm gear 7 that are connected to the worm 5 rotate respectively, and the rotation direction of the wheel worm gear 6 and the cultiva...

Embodiment 3

[0027] Such as Figure 1-Figure 4 In the anti-heel-rotating cultivating knife reverse micro tillage machine shown, the handrail 1 is connected to the frame 2, and the power 3 is connected to the frame 2. The power 3 is connected to the wheel 13 and the tiller 14 through the transmission mechanism 4, and is located on the handrail 1. The clutch switch 16 is connected to the transmission mechanism 4 through the connection line 17. The transmission mechanism 4 includes an inner toothed belt 15 which is sleeved and connected between the driving wheel 10 and the tension pulley 18. The inner tooth surface of the inner toothed belt 15 is connected to the The driving wheel 10 fits loosely, and the non-internal tooth surface of the belt inner toothed belt 15 fits loosely with the tensioning wheel 18. The thickness of the belt inner toothed belt 15 is 1 cm, and the depth of the inner teeth is 1 cm. The tension wheel 18 is connected, and the distance between the belt retaining member 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com