Multifunctional full-automatic potato combine harvester

A combined harvester, fully automatic technology, applied in the direction of excavating harvesters, harvesters, excavators, etc., can solve the problems of increased labor intensity, inability to classify and collect fruits of different sizes, and inability to classify and collect fruits and stones, etc. To achieve the effect of reducing labor costs and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

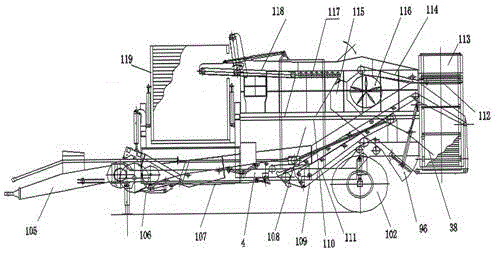

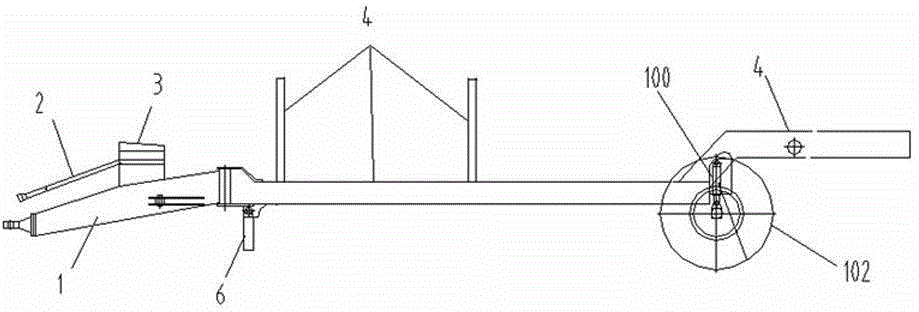

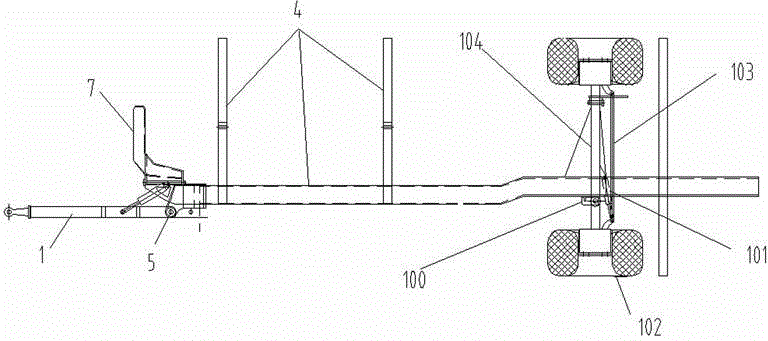

[0063] see figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes steering traction mechanism 105, machine head mechanism, feeding shovel mechanism 106, first seedling fruit conveying mechanism 107, second seedling killing conveying mechanism 109, the third fruit stone conveying mechanism 111, the fourth lifting conveying mechanism 113. The fifth turning conveying mechanism 112, the sixth winnowing conveying mechanism 114, the winnowing mechanism 116, the stone material conveying mechanism 115, the size separating mechanism 117, the seventh entering large silo conveying mechanism 118, and the large silo discharging conveying mechanism 119 1. Small silo discharge conveying mechanism 108, the sixth winnowing conveying mechanism 114, winnowing mechanism 116, stone material conveying mechanism 115, and siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com