Sampling device and method for material flows of each outlet of multistage centrifugal extractor

A sampling device and extractor technology, which is applied in sampling devices, liquid solution solvent extraction, etc., to achieve the effect of convenient manipulator operation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

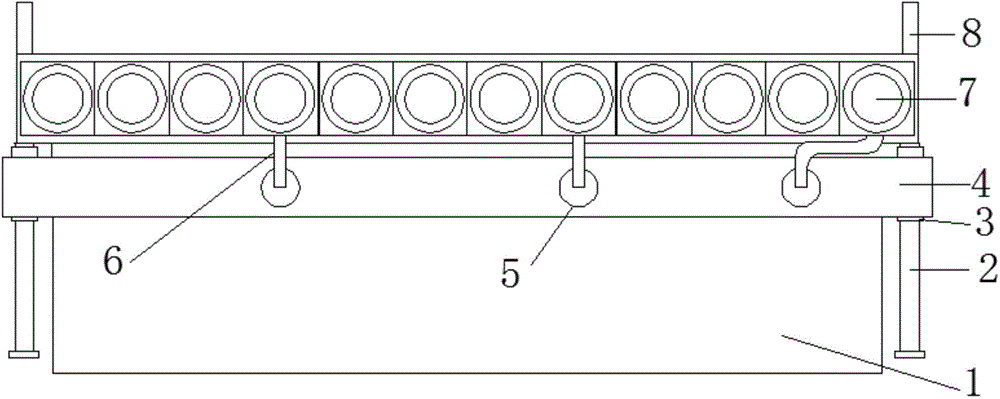

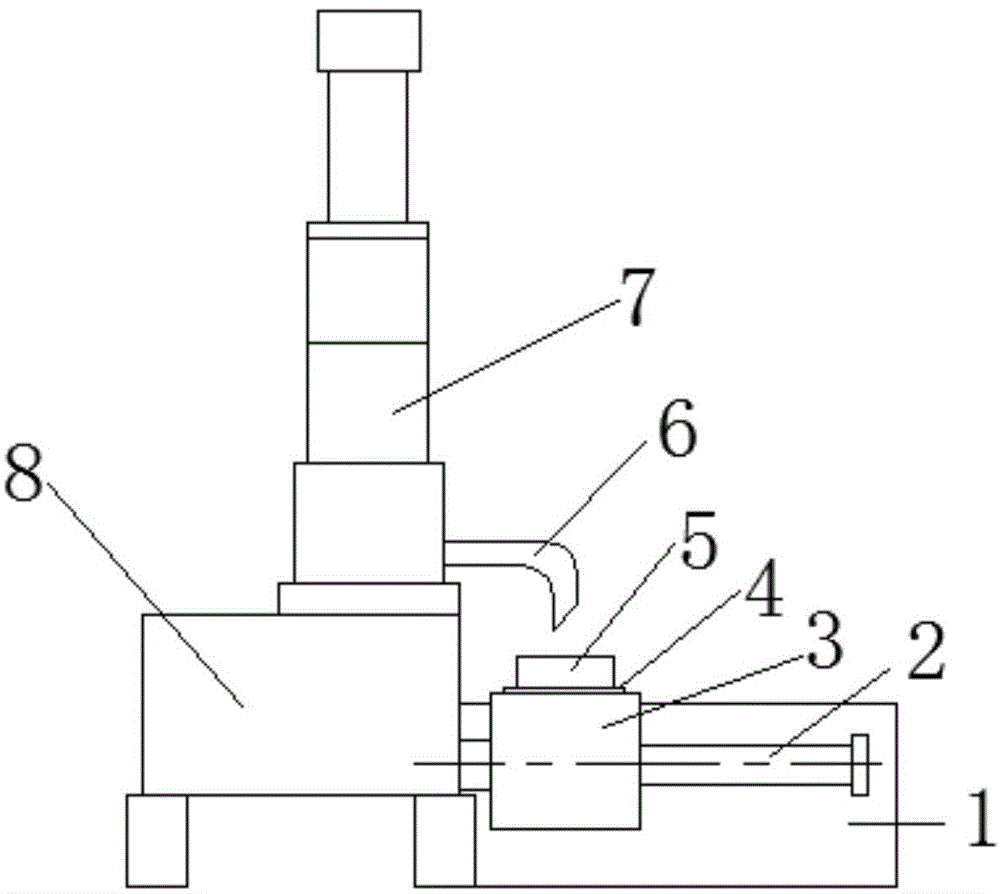

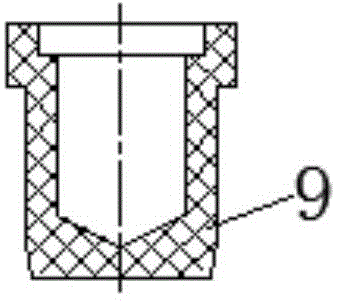

[0029] A φ10 centrifugal extractor with a 40-stage drum diameter of 10mm was used to conduct a verification experiment of the TRPO process for removing actinides in high-level waste liquid in the equipment room, and the feed liquid used was real high-level waste liquid. There are 10 inlet materials and 7 outlet streams in the whole experimental system, and the flow rate of the outlet streams is 48m L / h. When starting the strong radioactivity experiment, start the 40-stage φ10 centrifugal extractors to make them run at 4200r / min, and feed each material liquid to the 40-stage centrifugal extractor system according to the set process flow rate. When the entire 40-stage centrifugal extractor system is When the outlet pipe 6 has liquid flowing out, the sampling of each outlet stream can be carried out. When sampling at each outlet, first place the sampling cups 9 on the placement holes 5 of the sampling cups on the slide 4 with a manipulator, and then use the manipulator installed ...

Embodiment 2

[0031] A φ10 centrifugal extractor with a 32-stage drum diameter of 10mm was used to conduct a verification experiment of the process flow for removing strontium and cesium elements in high-level waste liquid in the equipment room, and the material liquid used was real high-level waste liquid. There are 8 inlet materials and 5 outlet streams in the whole experimental system, and the flow rate of the outlet streams is 80m L / h. When starting the strong radioactivity experiment, start the 32-stage φ10 centrifugal extractors to make them run at 3800r / min, and then feed each feed liquid to the 32-stage centrifugal extractor system according to the set process flow rate. When the entire 32-stage centrifugal extractor system is When the outlet pipe 6 has liquid flowing out, the sampling of each outlet stream can be carried out. When sampling at each outlet, first place the sampling cup 9 on the placement hole 5 of each sampling cup on the slide 4 with the manipulator, and then move t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com