Self-unloading horizontal na 131 iProduction device

A production device and self-unloading technology, which can be used in radiation-converting chemical element devices, nuclear engineering, etc., and can solve the problems of large amount of radioactive solid waste, small single production capacity, and no real-time monitoring function of tail gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

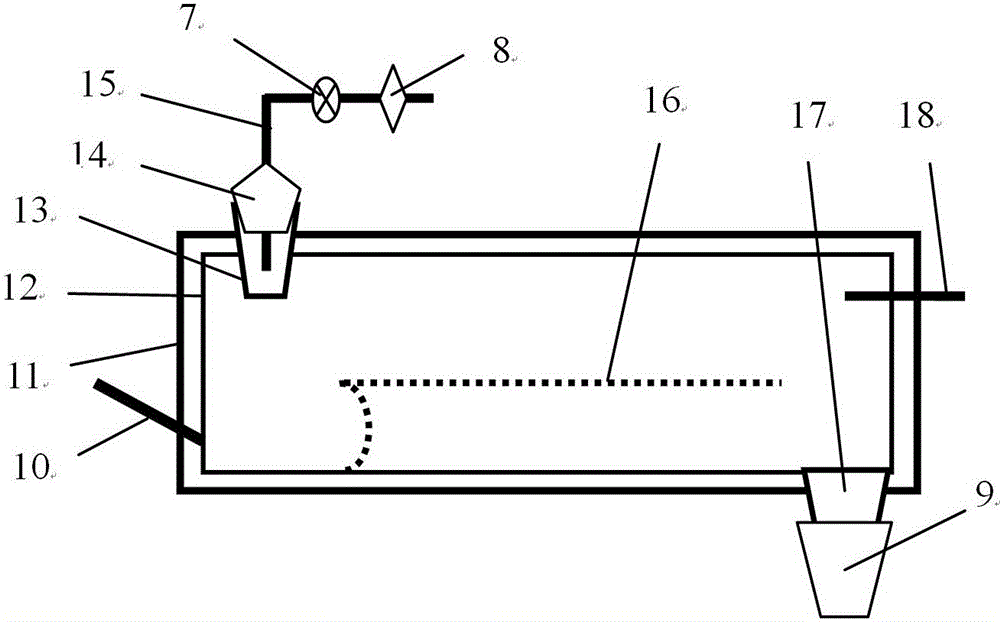

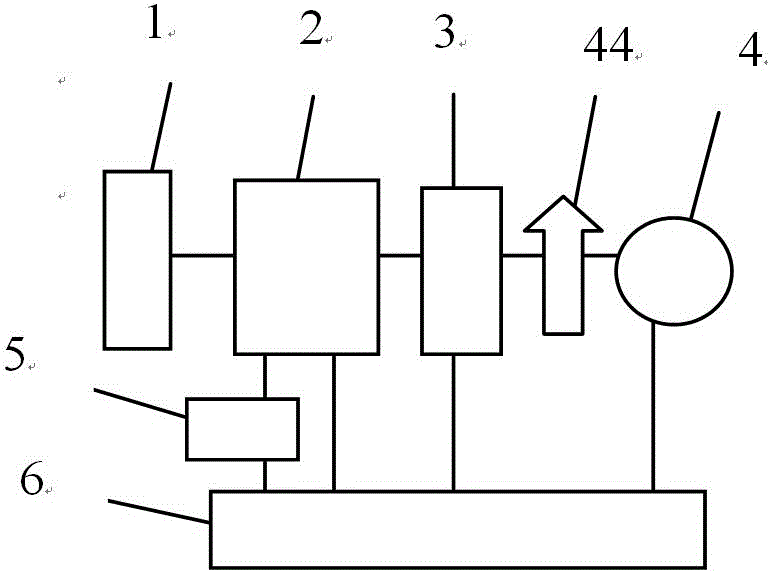

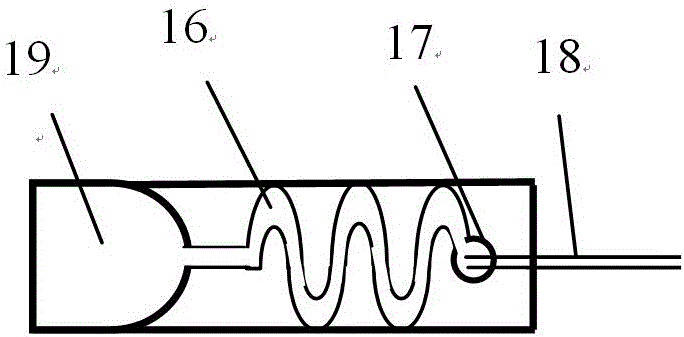

[0025] figure 1 For the self-unloading horizontal Na of the present invention 131 Structural block diagram of I production device, figure 2 It is the structural representation of distiller among the present invention, image 3 It is a structural representation of the bottom of the quartz furnace in the present invention, Figure 4 It is a structural schematic diagram of the catcher in the present invention, Figure 5 It is a structural schematic diagram of the exhaust gas monitor in the present invention. exist Figure 1~Figure 5 In, the horizontal Na of the present invention 131 1 production device, comprises platform 1, distiller 2, catcher 3, tail gas monitor 44, vacuum pump 4, lifting table 5, controller 6, and its connection relation is, described distiller 2 places platform 1 and fixedly connected with the platform 1, the distiller 2, the catcher 3, the tail gas monitor 44, and the vacuum pump 4 are connected sequentially through pipelines, the lifting table 5 is ...

Embodiment 2

[0039] The structure of this embodiment is the same as that of Embodiment 1, except that the angle between the heating furnace and the horizontal plane of the stand is set at 20 degrees.

Embodiment 3

[0041] The structure of this embodiment is the same as that of Embodiment 1, except that the angle between the heating furnace and the horizontal plane of the stand is set at 30 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com