A high-temperature biochemical processor for food waste and its control method

A technology of biochemical processor and kitchen waste, which is applied in the direction of solid waste removal, etc., can solve the problems that kitchen waste cannot be effectively treated, and residues and waste gas cannot be properly recycled and reused, so as to avoid aerosol pollution and secondary pollution. Secondary pollution, convenient recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

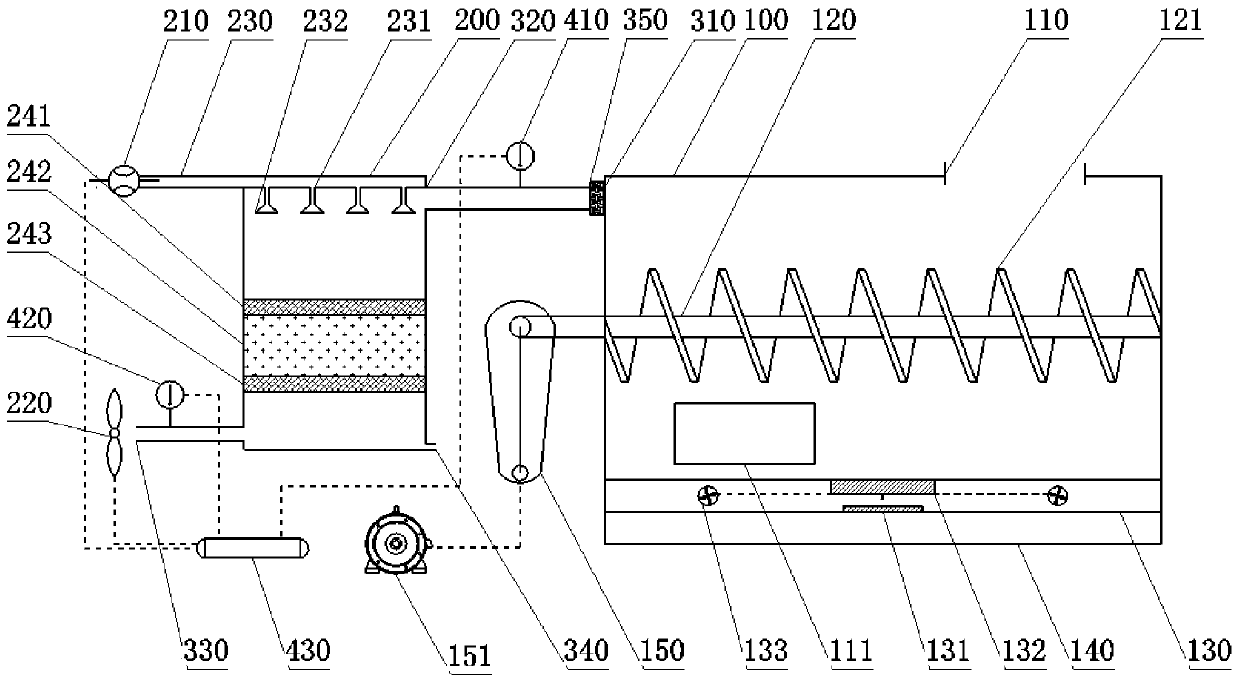

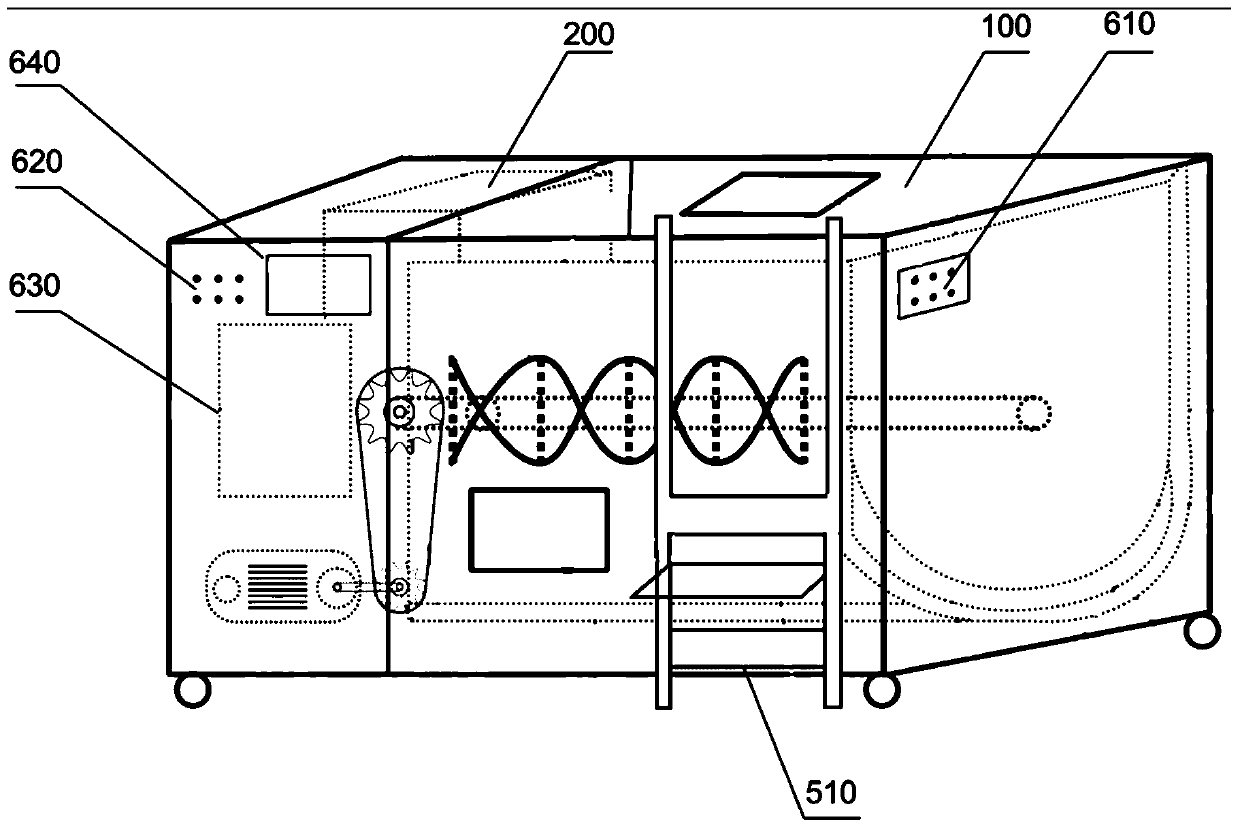

[0035] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a high-temperature biochemical treatment machine for food waste, which includes a fermentation bin 100 and a dedusting and deodorizing purification tower 200;

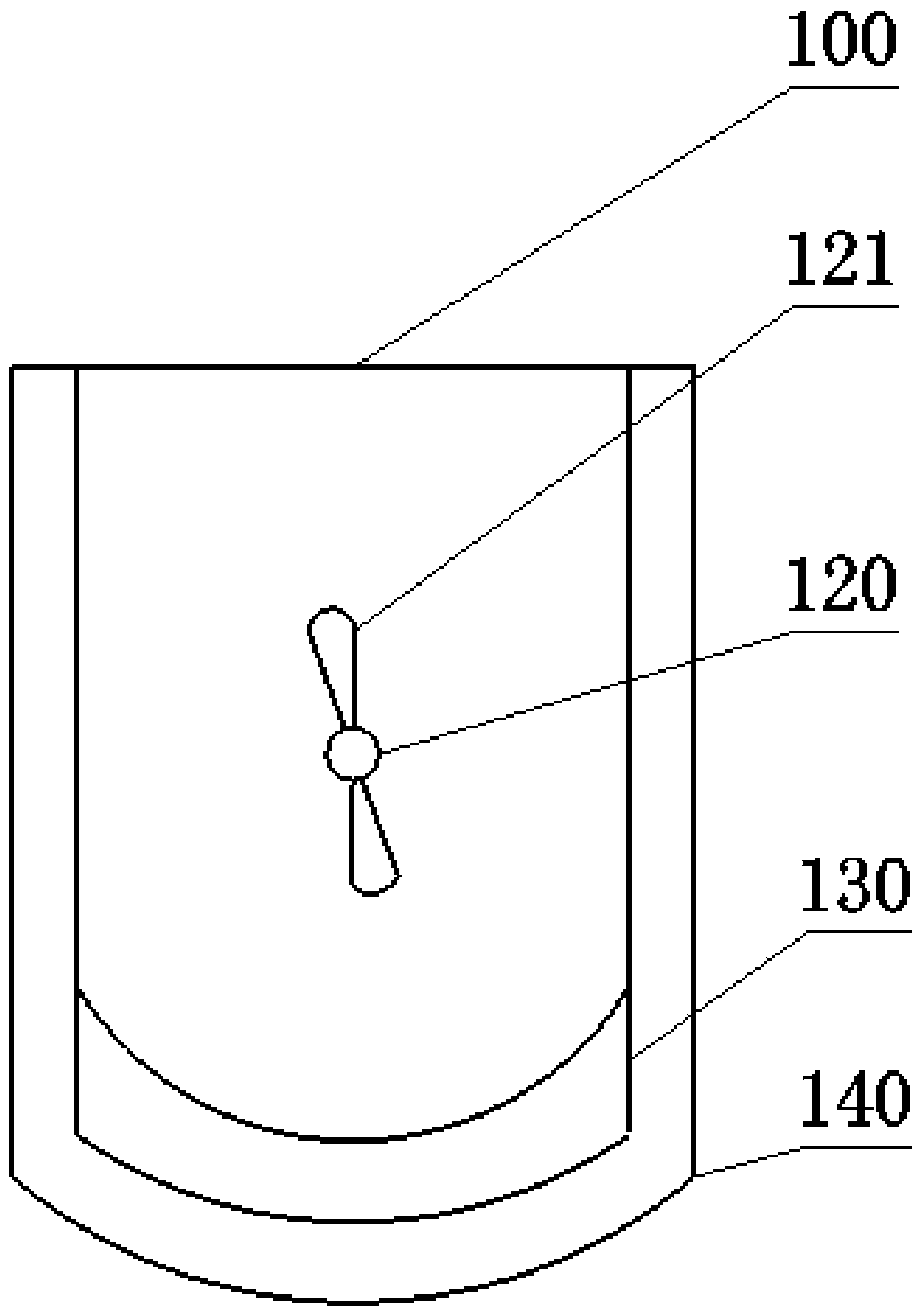

[0036] Wherein, the fermentation bin 100 is a closed chamber with a U-shaped cross section. The top of the fermentation bin 100 is provided with a feed port 110, and the front is provided with a discharge port 111. Through the feed 110, the food waste can be poured from top to bottom. into the fermentation bin, the treated material can be discharged from the outlet 111 through the outlet 111, and at the same time, the biodegradable strains are put into the fermentation bin 100 from the feed inlet 110 after pouring the kitchen w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com